Granite bases are the core structural elements of many precision machines, providing stability, rigidity, and vibration resistance essential for maintaining high accuracy. While the production of a granite base demands exceptional craftsmanship and strict quality control, the process does not end when machining and inspection are completed. Proper packaging and transportation are equally crucial to ensure that these precision components arrive at their destination in perfect condition.

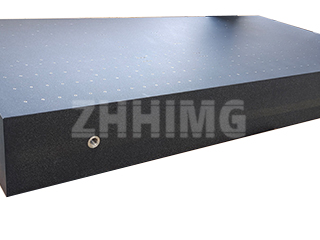

Granite is a dense yet brittle material. Despite its strength, improper handling can cause cracks, chipping, or deformation of the precision surfaces that define its function. Therefore, every step of packaging and transportation must be scientifically planned and meticulously executed. At ZHHIMG®, we treat packaging as a continuation of the manufacturing process—one that protects the accuracy our clients depend on.

Before shipment, each granite base undergoes a final inspection to verify dimensional accuracy, flatness, and surface finish. Once approved, the component is thoroughly cleaned and coated with a protective film to prevent dust, moisture, or oil contamination. All sharp edges are covered with foam or rubber padding to prevent impact during movement. The base is then securely fixed inside a customized wooden crate or steel-reinforced frame designed according to the component’s weight, size, and geometry. For large or irregularly shaped granite bases, reinforced support structures and vibration-damping pads are added to minimize mechanical stress during transit.

Transportation requires equal attention to detail. During loading, specialized cranes or forklifts with soft straps are used to avoid direct contact with the granite surface. Vehicles are selected based on stability and shock resistance, and routes are carefully planned to reduce vibration and sudden jolts. For international shipments, ZHHIMG® follows ISPM 15 export standards, ensuring compliance with customs regulations and providing safe delivery across global destinations. Each crate is clearly labeled with handling instructions such as “Fragile,” “Keep Dry,” and “This Side Up,” so every party in the logistics chain understands how to manage the cargo properly.

Upon arrival, customers are advised to inspect the packaging for visible signs of impact before unpacking. The granite base should be lifted with the proper equipment and stored in a stable, dry environment before installation. Following these simple yet crucial guidelines can effectively prevent hidden damage that might affect the long-term precision of the equipment.

At ZHHIMG®, we understand that precision doesn’t stop at production. From the selection of our ZHHIMG® Black Granite to the final delivery, every stage is handled with professional care. Our advanced packaging and logistics processes ensure that each granite base—no matter how large or complex—arrives at your facility ready for immediate use, maintaining the accuracy and performance that define our brand.

Post time: Oct-27-2025