In today’s high-end manufacturing landscape, accuracy is no longer a competitive advantage—it is a baseline requirement. As industries such as aerospace, semiconductor fabrication, photonics, and advanced metrology continue to push the limits of precision, the materials used inside measurement systems and optical equipment have become just as important as software algorithms or control systems. This is where industrial ceramic solutions, including precision ceramic for CMM, precision ceramic for photonics, and advanced precision SiN ceramic, are playing an increasingly decisive role.

Industrial ceramic materials have evolved far beyond their traditional image as simple wear-resistant parts. Modern technical ceramics are engineered materials with carefully controlled microstructures, offering predictable mechanical, thermal, and chemical performance. Compared with metals, ceramics provide superior dimensional stability, lower thermal expansion, and excellent resistance to corrosion and aging. These characteristics are critical in environments where microns—or even nanometers—matter.

In coordinate measuring machines, or CMMs, structural stability is the foundation of reliable measurement. Any thermal deformation, vibration, or long-term material creep can directly translate into measurement uncertainty. Precision ceramic for CMM applications addresses these challenges at the material level. Ceramic bridges, guideways, bases, and structural components maintain their geometry over time, even under fluctuating ambient temperatures. This stability allows CMM systems to deliver consistent measurement results without excessive environmental compensation or frequent recalibration.

Unlike traditional granite or metal structures, advanced industrial ceramic components offer a unique balance of stiffness and low mass. This combination improves dynamic performance, enabling faster probing speeds while maintaining measurement accuracy. As automated inspection becomes more common in smart factories, this dynamic stability is increasingly valuable. Precision ceramic for CMM systems supports higher throughput without compromising data integrity, making it well suited for modern quality control environments.

Precision ceramic for photonics applications faces an even more demanding set of requirements. Photonic systems depend on exact alignment, optical path stability, and resistance to thermal drift. Even minor dimensional changes can affect beam alignment, wavelength stability, or signal integrity. Ceramic materials, particularly high-purity alumina and silicon nitride ceramics, provide the thermal and mechanical stability needed to maintain precise optical alignment over long operating periods.

In laser systems, optical benches, and photonic measurement platforms, ceramic structures act as silent enablers of performance. Their low coefficient of thermal expansion helps ensure that optical components remain aligned despite temperature changes caused by environmental conditions or system operation. At the same time, the inherent damping properties of ceramics reduce the impact of vibration, which is essential for high-resolution optical measurement and laser processing.

Precision SiN ceramic, or silicon nitride ceramic, represents one of the most advanced classes of industrial ceramic materials currently used in high-precision equipment. Known for its exceptional strength, fracture toughness, and thermal shock resistance, silicon nitride combines mechanical robustness with outstanding dimensional stability. These properties make precision SiN ceramic particularly suitable for high-load, high-speed, or thermally demanding applications.

In metrology and photonics equipment, precision SiN ceramic components are often used where both stiffness and reliability are critical. They retain their mechanical properties across a wide temperature range and resist wear even in demanding operating conditions. This long-term reliability reduces maintenance requirements and supports stable system performance throughout the equipment’s service life. For manufacturers and end users alike, this translates into lower total cost of ownership and higher confidence in measurement results.

From a broader perspective, the growing adoption of industrial ceramic materials reflects a shift in how precision systems are designed. Instead of compensating for material limitations through complex software or environmental controls, engineers are increasingly selecting materials that inherently support accuracy. Precision ceramic for CMM and photonics applications embodies this philosophy by offering stability, predictability, and durability at the structural level.

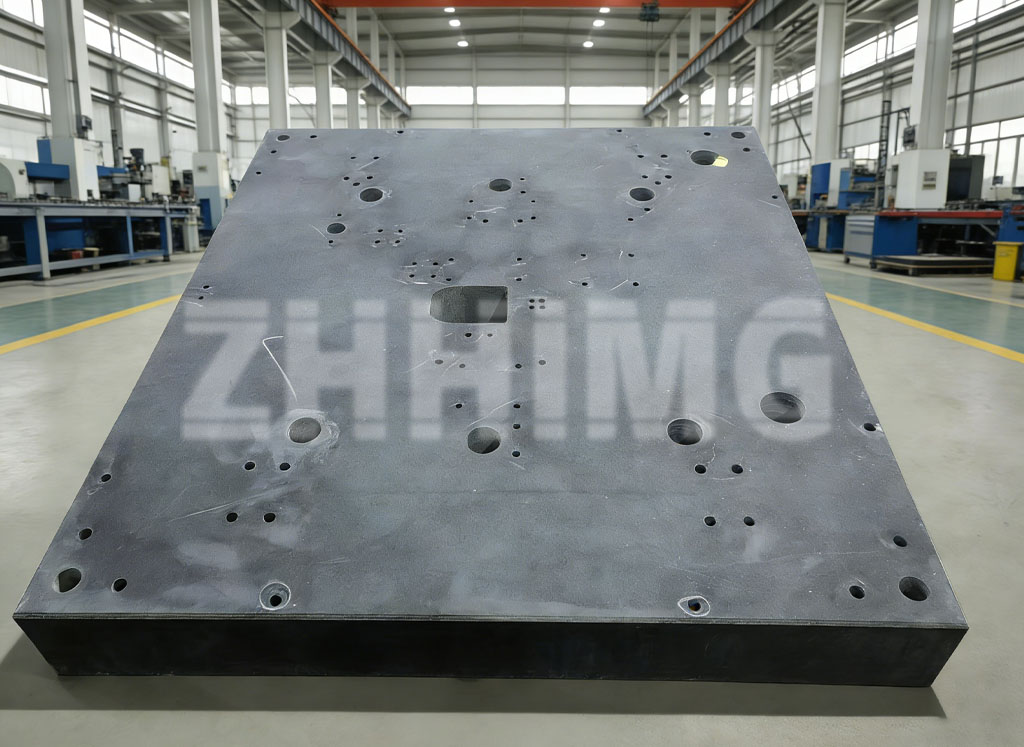

At ZHHIMG, ceramic engineering is approached as a discipline that combines material science with precision manufacturing. Industrial ceramic components are not treated as generic parts, but as mission-critical elements tailored to specific applications. Whether used in CMM structures, photonics platforms, or advanced inspection systems, each ceramic component is manufactured with strict control over flatness, geometry, and surface quality. This attention to detail ensures that the material’s inherent advantages are fully realized in real-world applications.

As industries continue to demand higher accuracy, faster measurement cycles, and more reliable optical systems, the role of advanced ceramics will only expand. Industrial ceramic solutions, including precision ceramic for CMM, precision ceramic for photonics, and precision SiN ceramic components, are no longer niche technologies. They are becoming foundational materials for the next generation of precision equipment.

For engineers, system designers, and decision-makers in Europe and North America, understanding the value of ceramic materials is essential when planning future investments in metrology and photonics. By choosing the right ceramic solutions at the design stage, it is possible to achieve higher accuracy, greater stability, and longer service life—outcomes that directly support quality, efficiency, and long-term competitiveness in advanced manufacturing.

Post time: Jan-13-2026