Precision measurement has always been a defining factor in advanced manufacturing, but the expectations placed on modern inspection systems are changing rapidly. As production volumes increase, product geometries become more complex, and tolerance requirements tighten, traditional inspection methods are no longer sufficient. This shift has placed the coordinate measuring machine in metrology at the center of quality assurance strategies across aerospace, automotive, electronics, and precision engineering industries.

Today, metrology is no longer limited to static inspection rooms or isolated quality departments. It has become an integrated part of intelligent manufacturing systems, driven by automation, digital control, and data connectivity. In this context, technologies such as the robot CMM, computer controlled coordinate measuring machine, and portable inspection solutions are redefining how and where measurements are performed.

The concept of a robot CMM reflects the broader trend toward automation and flexibility in measurement. By combining robotic motion with coordinate measuring technology, manufacturers can achieve higher throughput while maintaining consistent inspection accuracy. Robotic systems are particularly valuable in production environments where repetitive measurement tasks must be executed reliably and with minimal human intervention. When properly integrated, robot-based CMM solutions support inline inspection, rapid feedback, and reduced cycle times, all of which contribute directly to improved process control.

At the heart of these automated solutions lies the computer controlled coordinate measuring machine. Unlike manually operated systems, a computer controlled coordinate measuring machine executes programmed measurement routines with high repeatability and traceability. Measurement paths, probing strategies, and data analysis are all governed by software, ensuring consistent results across shifts, operators, and production batches. This level of control is essential for manufacturers operating under strict international standards and customer-specific quality requirements.

The growing interest in CNC CMM for sale listings across global markets reflects this demand for automation and reliability. Buyers are no longer looking solely at accuracy specifications; they are evaluating system stability, long-term performance, software compatibility, and ease of integration into existing production lines. A CNC CMM represents an investment in process efficiency as much as in measurement capability, especially when paired with robust structural components and stable base materials.

Despite the rise of fully automated systems, flexibility remains a key consideration in modern metrology. This is where solutions such as the CMM portable arm play an important role. Portable measuring arms allow inspectors to bring the measurement system directly to the part, rather than transporting large or delicate components to a fixed CMM. In applications involving large assemblies, on-site inspection, or field service, portable arms provide practical measurement capability without sacrificing accuracy.

Within the broader coordinate measuring machine in metrology landscape, these portable systems complement rather than replace traditional bridge-type and gantry CMMs. Each solution serves a specific purpose, and modern quality strategies often involve a combination of fixed, portable, and automated measurement systems. The challenge lies in ensuring that all measurement data remains consistent, traceable, and aligned with enterprise quality standards.

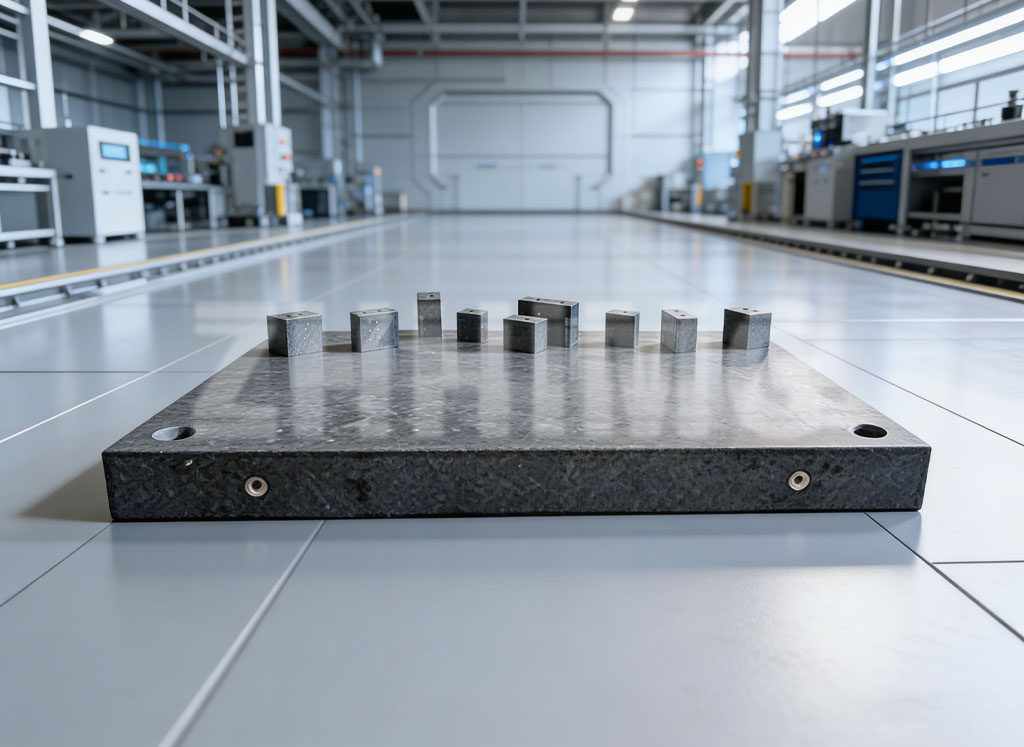

Structural stability remains a fundamental requirement regardless of the chosen CMM configuration. Whether supporting a robot CMM, a CNC inspection system, or a hybrid measurement cell, the mechanical foundation directly influences measurement reliability. Materials such as precision granite are widely used for CMM bases and structural components due to their low thermal expansion, excellent vibration damping, and long-term dimensional stability. These properties are especially critical in automated and computer controlled coordinate measuring machines, where even minor structural drift can affect measurement results over time.

ZHONGHUI Group (ZHHIMG) has long supported the global metrology industry by supplying precision granite components and structural solutions for advanced measuring systems. With extensive experience in ultra-precision manufacturing, ZHHIMG works closely with CMM manufacturers, automation integrators, and end users to deliver custom granite bases, guideways, and machine structures designed for demanding measurement environments. These components are widely applied in robot CMM installations, CNC coordinate measuring systems, and hybrid inspection platforms.

As digital manufacturing continues to evolve, measurement systems are increasingly connected to manufacturing execution systems, statistical process control platforms, and digital twins. In this environment, the role of the coordinate measuring machine in metrology extends beyond inspection to become a source of real-time process intelligence. Automated data collection, analysis, and feedback enable manufacturers to detect deviations early and optimize production parameters proactively.

The future of metrology will be shaped by greater automation, increased mobility, and higher expectations for accuracy and efficiency. Robot CMM systems will continue to expand their presence on production floors, while portable arms and computer controlled coordinate measuring machines will support flexible and decentralized inspection strategies. Across this evolving landscape, the importance of stable structures, precise motion control, and reliable materials remains unchanged.

For manufacturers evaluating new inspection solutions or exploring CNC CMM for sale options, a system-level perspective is essential. Accuracy specifications alone do not define performance. Long-term stability, environmental adaptability, and structural integrity are equally critical to achieving consistent measurement results.

As industries move toward smarter, more connected production environments, coordinate measuring machines will remain a cornerstone of modern metrology. Through the thoughtful integration of robotics, computer control, and precision-engineered structures, today’s measurement systems are not only keeping pace with manufacturing innovation but actively enabling it.

Post time: Jan-06-2026