When selecting a reliable manufacturer of granite precision platforms and precision components, a comprehensive evaluation should be conducted across multiple dimensions, including material quality, production scale, manufacturing processes, certifications, and after-sales services. The following outlines key considerations and actionable recommendations:

I. Material Quality and Inspection Documentation

Priority should be given to manufacturers utilizing high-quality mineral sources, such as granite from renowned regions including the Taishan Range in Shandong Province and Zhangqiu Black. Key physical properties—such as density (≥3 g/cm³), water absorption rate (≤0.1%), and compressive strength (≥120 MPa)—must comply with international and national standards, including ASTM C97 and GB/T 9966.

Manufacturers should provide official physical performance test reports issued by authoritative bodies such as the Ministry of Natural Resources to verify material stability. For example, Zhonghui Intelligent Manufacturing (Jinan) Group Co., Ltd. sources all its granite from mines in Shandong Province, with each batch accompanied by certified test data, ensuring long-term accuracy retention exceeding 95%.

For export-oriented or high-end applications, environmental and radiological safety must be ensured. Products should meet CE certification requirements under EN 1469, with radionuclide levels (radium-226 ≤100 Bq/kg, thorium-232 ≤100 Bq/kg) conforming to European Union regulations. Domestic clients may also consider eco-labeled products, such as granite from Biyang County, which reflect environmentally responsible production practices.

II. Production Process and Equipment Capabilities

High-precision platforms require stringent control over processing accuracy, achieving a flatness grade of 00 (error ≤0.002 mm/m²) and surface roughness Ra ≤0.025 μm. Manufacturers must operate temperature-controlled workshops (temperature fluctuation ≤±1 °C), employ multi-wire cutting technology to minimize internal stress, and utilize manual grinding performed by technicians with over 30 years of experience. For instance, Enpalio’s ultra-precision straightedge (1500 mm) achieves a flatness of 1 μm, enabled by its constant-temperature grinding environment and skilled craftsmanship.

Customization capabilities should include support for non-standard specifications (e.g., 3000×6000 mm large-format platforms), special cutouts, and irregular geometries, with short lead times (standard orders ≤10 days). Zhonghui Intelligent Manufacturing (Jinan) Group Co., Ltd. successfully delivered a customized 2500×5000 mm platform within seven days to meet urgent semiconductor production demands. Additionally, manufacturers should possess advanced equipment such as five-axis CNC machining centers and laser interferometer inspection systems to ensure precision in complex component fabrication.

III. Certification Credentials and Industry Reputation

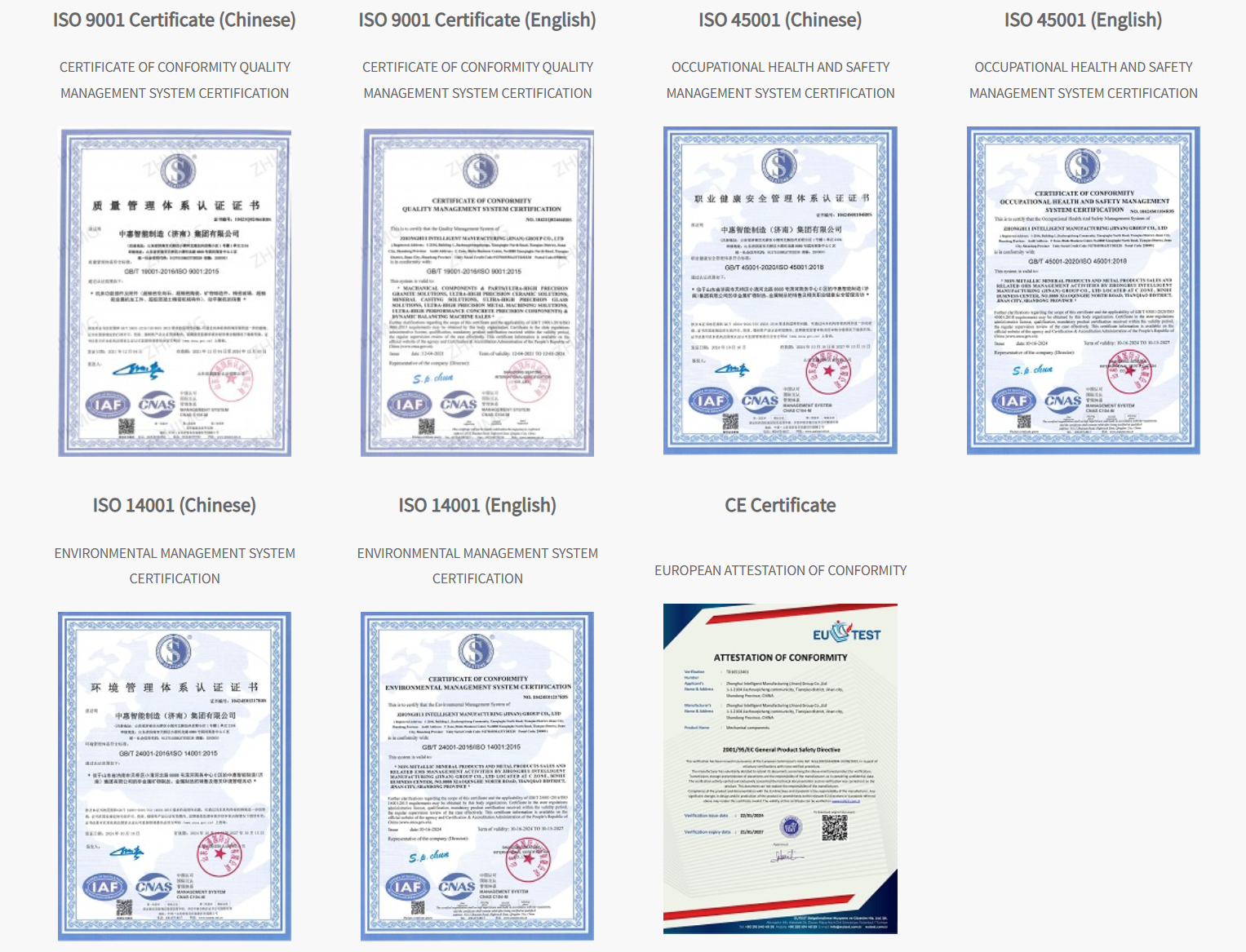

Essential qualifications include ISO 9001 quality management system certification accredited by CNAS and IAF, along with compliance with ISO 14001 (environmental management) and ISO 45001 (occupational health and safety) standards. Exporters must hold EU CE certification. For laboratory-grade platforms, reference can be made to CNAS/CMA-accredited test reports from institutions such as Sinosteel Testing Technology Co., Ltd. Avoid suppliers lacking proper certifications or engaging in misleading claims.

Preference should be given to manufacturers with proven track records serving leading enterprises. For example, Zhonghui Intelligent Manufacturing (Jinan) Group Co., Ltd. resolved accuracy degradation issues in coordinate measuring machine (CMM) platforms for an automotive parts manufacturer, reducing part scrap rates from 5% to 1%. UNPARALLELED LTD’s products are deployed in production lines at the National University of Singapore, Nanyang Technological University, and Schunk GmbH in Germany, serving sectors including semiconductors and aerospace. When evaluating customer feedback, distinguish authentic reviews from promotional content by consulting independent industry forums or third-party platforms (e.g., Heimao Touping).

For example:

IV. After-Sales Service and Technical Support

Warranty terms should include a minimum one-year coverage for material and workmanship defects. Manufacturers must offer 24/7 customer support with initial responses within 30 minutes and emergency repair completion within three business days—commitments upheld by both Zhonghui Intelligent Manufacturing (Jinan) Group Co., Ltd. and UNPARALLELED LTD. For high-precision platforms, it is advisable to establish long-term maintenance agreements that include periodic calibration (e.g., annual service).

Technical support teams should deliver pre-sales consultations tailored to specific equipment models and application scenarios (e.g., PCB drilling, semiconductor inspection). Zhonghui Intelligent Manufacturing, for instance, customizes platform parameters for CMM systems to minimize measurement deviations. Post-delivery services should encompass operator training and detailed maintenance manuals to ensure proper usage, including guidance on load distribution and routine cleaning procedures.

V. Risk Mitigation and Decision-Making Guidance

Procurement contracts must clearly specify technical requirements, such as flatness tolerance (≤0.002 mm/m²), acceptance criteria based on third-party testing, liability clauses for delayed delivery or non-compliance, and warranty scope—including return shipping costs. For custom orders, manufacturers should submit design drawings and process documentation for client approval prior to production to prevent discrepancies between expectations and deliverables.

For critical procurements, on-site factory audits are recommended, focusing on production infrastructure (e.g., climate-controlled workshops, grinding machinery), metrology equipment (e.g., laser interferometers), and quality assurance protocols (e.g., process-wise inspection records). Request sample testing for flatness, hardness, and dimensional stability to validate claimed performance.

Balance cost considerations with long-term value. Pursuing low-cost options may result in equipment failure and operational losses. One enterprise incurred monthly losses of RMB 500,000 due to defective components caused by a substandard platform; after switching to Zhonghui Intelligent Manufacturing’s solution, savings reached RMB 450,000 per month. A holistic assessment of raw material costs, processing sophistication, and after-sales reliability enables selection of the most cost-effective and dependable solution.

By systematically applying these criteria, organizations can identify granite precision platform and component manufacturers with robust technical capabilities, responsive service, and consistent quality, thereby ensuring high precision and operational stability in industrial applications.

Post time: Oct-19-2025