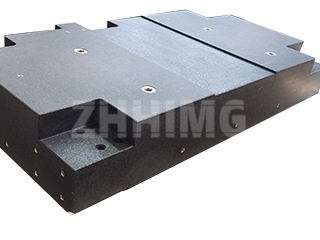

The granite machine bed component represents the zenith of structural stability in modern manufacturing. With their exceptional stiffness, inherent vibration dampening, and near-zero thermal expansion coefficient, these components—particularly those fabricated from high-density materials like our ZHHIMG® Black Granite—are indispensable for next-generation CNC machines, ultra-precision measuring equipment, and advanced laser systems. However, the performance of these high-accuracy components is only as good as their initial setup. Meticulous adherence to pre-installation protocols is essential to unlock the full potential and extend the operational lifespan of the entire system.

The journey to precision begins with an exhaustive inspection and preparation phase. Before installation, the component must pass a rigorous visual and dimensional audit. Engineers must meticulously check the granite surface for any micro-cracks, chipping, or handling damage that may have occurred during transit. More critically, the component’s certified dimensions and geometric accuracy—flatness, squareness, and parallelism—must be re-verified using advanced metrology tools, ensuring the bed meets the intended processing or measurement tolerances. Simultaneously, an environmental assessment is crucial. As a global supplier, ZHHIMG® requires users to ensure the mounting location conforms to strict temperature and humidity parameters, safeguarding the granite’s long-term stability against adverse conditions before the assembly process even begins.

During the installation process, control over the foundation is paramount. The receiving base must be rigid, perfectly level, and isolated from potential vibrations and settling issues. Any unevenness in the foundation will introduce localized stresses into the granite, which, despite its strength, will compromise the final geometric integrity. Precision leveling tools and shims must be employed to carefully control the horizontal alignment, while critical indicators like perpendicularity and parallelism must be controlled to the sub-micron level, reflecting the exacting standards of our own manufacturing environment. Furthermore, the joining and fastening of the granite bed to the rest of the machine structure requires specialized knowledge. Correctly rated fasteners and bonding agents must be used, applying specified torque values to ensure a rigid, stable connection without inducing excessive internal strain that could damage the granite or distort its precise geometry.

Before the system is handed over for production, a comprehensive commissioning and testing phase is mandatory. This stage involves functional tests of all integrated moving parts, such as linear guides and drive systems, to ensure smooth, unhindered movement without binding or unusual noise. This is immediately followed by a final system accuracy verification. Using traceable calibration equipment—like those from our partners such as Renishaw and WYLER—the assembled machine’s total geometric accuracy must be confirmed against the specified performance parameters. Any deviation must be immediately analyzed and corrected, guaranteeing the equipment is compliant with standards like German DIN or US ASME before any materials are processed. Finally, the operational safety systems must be checked, and personnel must receive thorough training on the correct handling and safety procedures mandated for high-precision machinery.

The final element of pre-use planning is the maintenance strategy. Although granite is known for its durability, proper care secures its longevity. A schedule for periodic cleaning using only soft cloths and neutral cleaners must be established, explicitly prohibiting abrasive tools that could scratch the precision-lapped surface. More importantly, a routine for lubricating mechanical components and treating exposed steel parts for rust prevention should be implemented. By meticulously following these comprehensive pre-installation and pre-use guidelines, manufacturers ensure that the ZHHIMG® Granite Machine Bed Component delivers the exceptional performance, extended service life, and unwavering stability it was engineered to provide.

Post time: Nov-17-2025