Precision engineering has always been defined by the ability to measure and manufacture components with extreme accuracy. In modern manufacturing, the demand for micron-level precision is not just a benchmark—it is a necessity. Universal length measuring instruments are at the heart of this pursuit, providing highly reliable measurements across a wide range of applications. But the question remains: how can their performance be further improved, and why are granite machine beds considered the gold standard for supporting these instruments?

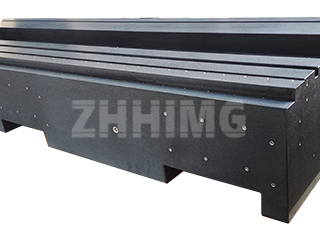

The granite machine bed for Universal length measuring instruments plays a crucial role in ensuring measurement stability. Unlike traditional metal bases, granite offers a combination of rigidity, thermal stability, and vibration damping that is unmatched in precision environments. When a universal length measuring instrument is mounted on a granite base, it benefits from a foundation that resists bending, warping, or thermal expansion, which are common sources of measurement errors. This ensures that every reading reflects the true dimensions of the object being measured, rather than distortions caused by the machine itself.

Granite support beams are another integral component in high-precision measurement setups. These beams provide structural reinforcement and alignment for the machine bed, ensuring that the measuring instruments remain perfectly parallel and stable. The natural damping properties of granite also help absorb vibrations from the surrounding environment, whether from nearby machinery or minor floor movements, further enhancing measurement reliability. For engineers and technicians, this combination of granite machine bed and support beams translates to confidence that every measurement is consistent and repeatable.

The use of a granite machine base for Universal length measuring instruments is particularly advantageous in environments where accuracy cannot be compromised. Industries such as aerospace, automotive, and high-tech manufacturing rely on these setups to achieve tolerances often within microns. The high density and rigidity of granite allow the base to maintain its shape over time, resisting wear from repetitive use and mechanical stress. Moreover, granite’s low coefficient of thermal expansion means that even when temperatures fluctuate, the measurements remain precise. This is essential in laboratories and manufacturing floors where environmental control is not always perfect.

A granite base for Universal length measuring instruments also contributes to long-term operational efficiency. Its durability reduces maintenance requirements compared to traditional metal or composite bases, and its resistance to corrosion ensures longevity even in humid or chemically active environments. Regular maintenance of the granite surface, including cleaning and polishing, preserves flatness and smoothness, which directly impacts measurement accuracy. Calibration routines become more reliable because the foundational surface remains consistent, providing a stable reference for high-precision inspections.

The applications of granite-based measurement platforms extend beyond simple linear measurements. Universal length measuring instruments supported by granite machine beds can be used for complex dimensional inspections, including flatness, straightness, and parallelism of components. The granite support beams enhance structural integrity, ensuring that multi-point measurements are accurate across the entire working surface. This is particularly important for large components or assemblies, where even slight misalignments can lead to significant deviations. By using granite as a base material, engineers can achieve precision that meets the strictest industry standards.

In addition to structural advantages, granite machine beds and bases provide excellent stability for digital and automated measurement systems. Modern universal length measuring instruments often include electronic sensors, data acquisition modules, and software for real-time analysis. The stable platform offered by granite ensures that vibrations, thermal shifts, or mechanical stress do not interfere with sensor readings. This allows manufacturers to integrate high-precision measurement data directly into quality control and production management systems, enabling faster decision-making and reducing the likelihood of defects reaching the final product.

Investing in granite machine beds, granite support beams, and granite bases for Universal length measuring instruments is not merely a matter of preference—it is a strategic decision that impacts product quality, operational efficiency, and long-term reliability. These granite components are engineered to provide the highest degree of stability, which directly influences the performance of measuring instruments. By combining universal length measuring machines with granite bases and support structures, manufacturers ensure that every measurement is accurate, repeatable, and traceable to international standards.

Ultimately, granite machine beds and their supporting elements form the foundation of modern precision measurement. They provide the rigidity, thermal stability, and vibration damping necessary to achieve reliable results in demanding industrial applications. Universal length measuring instruments mounted on granite bases perform at their best because the foundation itself contributes to measurement accuracy. For companies committed to maintaining the highest standards of quality and precision, understanding and implementing granite-based machine beds is essential. It is an investment that guarantees accuracy, reduces operational risk, and supports the long-term success of precision manufacturing.

Post time: Dec-02-2025