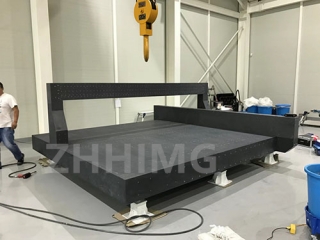

In the field of precision measurement, the stability of the measurement equipment base directly determines the reliability of the data. The measurement error problem caused by thermal deformation of cast iron bases has long plagued the manufacturing industry. However, the granite flatness measuring instrument platform launched by ZHHIMG, with its AAA-level accuracy certification that breaks through industry standards, provides a revolutionary solution for high-precision measurement.

The thermal deformation dilemma of cast iron bases: The Invisible Killer of measurement errors

Cast iron bases were once widely used in measuring equipment due to their low cost and strong rigidity. However, in practical applications, the drawback of their poor thermal stability has gradually emerged. The coefficient of thermal expansion of cast iron is as high as 11-12 ×10⁻⁶/℃. When the equipment is in operation or the ambient temperature fluctuates, it is very prone to thermal deformation. For instance, when the ambient temperature in the workshop changes by 5℃, the cast iron base may undergo a linear deformation of 0.0055-0.006mm. Such a minor change will directly cause the measurement reference to shift, multiplying the measurement error.

In addition, the heat conduction of the cast iron base is uneven. When the equipment is in operation, local heating will cause a "thermal gradient effect", resulting in distortion and deformation on the surface of the base. In flatness measurement, this deformation can cause a deviation in the relative position between the measuring probe and the object being measured, ultimately outputting incorrect measurement data. According to industry statistics, for measuring equipment with cast iron bases, errors caused by thermal deformation account for more than 40% of the total errors, seriously affecting the accuracy of product quality inspection.

The technological breakthrough of ZHHIMG granite platform: Eliminating thermal deformation from the root

The ZHHIMG granite flatness measuring instrument platform takes natural granite as the base material, solving the problem of thermal deformation from the essence of the material. The coefficient of thermal expansion of granite is only 5-7 ×10⁻⁶/℃, which is only half that of cast iron. Moreover, its internal structure is dense and uniform. Even under extreme temperature changes, it can maintain stable size and shape. Laboratory data show that in an environment with a temperature fluctuation of 20℃, the linear deformation of the granite platform is less than 0.0014mm, which is almost negligible.

In addition to material advantages, ZHHIMG adopts a patented ultra-precision processing technology. Through CNC grinding and polishing techniques, the flatness of the platform surface is enhanced to ±0.001mm/m, reaching the top level in the industry. Meanwhile, a unique honeycomb-shaped stress release structure is designed inside the platform, which further enhances rigidity while effectively disperses the minute deformations caused by thermal stress, ensuring that the measurement reference remains stable and reliable at all times.

Aaa-level precision certification: A quality commitment backed by authority

The ZHHIMG granite platform has passed the AAA-level precision certification by an international authoritative institution. This certification standard requires that the measurement error of the equipment be always controlled within ±0.3μm under multiple environmental changes such as temperature, humidity and vibration. To meet this standard, ZHHIMG has established a full-process quality control system: from the screening of raw granite ore, precision processing to the inspection of finished products, each link is strictly monitored by automated inspection equipment. For example, a laser interferometer is used to conduct micron-level scanning of the platform surface to ensure that the flatness error is optimized. The thermal stability of the platform is verified by simulating extreme environments through a constant temperature and humidity laboratory.

In practical applications, the ZHHIMG platform has demonstrated significant advantages in industries such as semiconductors, optical lenses, and precision molds. After a certain semiconductor enterprise introduced this platform, the flatness measurement error was reduced by 90%, and the product yield rate was increased by 15%, effectively solving the rework problem caused by measurement errors.

Against the backdrop of the manufacturing industry's upgrade towards high precision and intelligence, the ZHHIMG granite flatness measuring instrument platform has redefined the standard of precision measurement with its ultimate control over thermal deformation and AAA-level accuracy certification. It not only provides reliable measurement guarantees for enterprises, but also promotes the industry's technological leap from "empirical judgment" to "precise detection".

Post time: May-12-2025