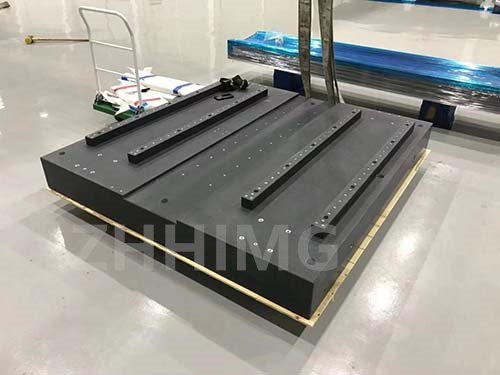

In the realm of precision manufacturing, laser bonding requires pinpoint accuracy to ensure the integrity and functionality of bonded components. Granite machine bases, especially those from trusted providers like ZHHIMG®, play a pivotal role in achieving these precise results. Here’s how their unique properties enhance the performance of laser bonding equipment.

Unrivaled Stability for Consistent Alignment

Laser bonding demands that components remain perfectly aligned throughout the process. Granite machine bases, with a high density of around 3100 kg/m³, offer an exceptionally stable foundation. The weight and rigidity of granite resist external forces that could otherwise cause the bonding equipment to shift or tilt. Whether it’s the vibrations from nearby machinery or the movement of operators on the factory floor, the stable base ensures that the laser source and bonding platform maintain their precise relative positions. This stability is crucial for achieving consistent bond quality, as even the slightest misalignment can lead to weak joints or bonding failures.

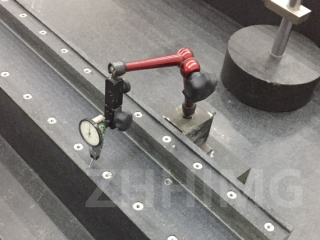

Superior Vibration Damping for Error - Free Bonding

The high - energy pulses of lasers in bonding operations can generate internal vibrations within the equipment. Additionally, ambient vibrations from the manufacturing environment pose a significant threat to precision. Granite’s natural vibration - damping capabilities are a game - changer in this scenario. Its unique internal structure, composed of interlocking mineral grains, effectively absorbs and dissipates vibration energy. By reducing these vibrations, granite machine bases prevent the laser beam from deviating off - target. As a result, the bonding process can occur with greater accuracy, minimizing the risk of uneven heat distribution and ensuring uniform bond strength across the joint.

Exceptional Thermal Resistance for Precision Preservation

Temperature fluctuations are inevitable in manufacturing environments, and they can have a profound impact on laser bonding accuracy. Granite’s low thermal expansion coefficient is a key advantage here. Unlike many metals that expand and contract significantly with temperature changes, granite maintains its dimensions even under varying thermal conditions. In laser bonding, where thermal stability is essential to keep optical components in alignment and prevent thermal stress in the bonded materials, a granite machine base acts as a safeguard. It ensures that the laser’s focal point remains constant and that the positioning of components doesn’t shift due to heat, thereby enabling precise and repeatable bonding results.

Chemical Inertness for Long - Term Reliability

Laser bonding may involve the use of various chemicals for surface preparation or process enhancement. Granite’s chemical inertness makes it resistant to corrosion from these substances. This property protects the integrity of the machine base over time, ensuring that it continues to provide a stable and accurate platform for laser bonding operations. By choosing a granite machine base, manufacturers can avoid the potential issues associated with chemical - induced degradation, such as warping or weakening of the base material, which could compromise the precision of the bonding process.

In conclusion, granite machine bases are indispensable for achieving precise laser bonding results. Their stability, vibration - damping, thermal resistance, and chemical inertness work in harmony to create an optimal environment for high - precision bonding. When seeking to enhance the quality and reliability of laser bonding operations, investing in a high - quality granite machine base, like those offered by ZHHIMG®, is a strategic decision that pays dividends in the form of consistent, accurate, and defect - free bonding outcomes.

Post time: Jun-03-2025