In the highly precise field of semiconductor manufacturing, even the slightest vibration can significantly impact the performance of wafer slotting machines, leading to defects and yield losses. Granite machine bases have emerged as a game - changing solution, offering unparalleled vibration - reduction capabilities crucial for maintaining the integrity of wafer processing.

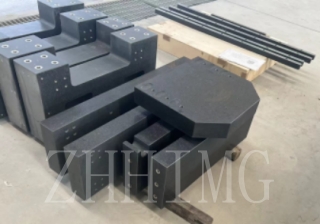

High Density and Inertia for Vibration Suppression

Granite’s high density, typically ranging from 2,600 to 3,100 kg/m³, provides substantial inertia. When integrated into wafer slotting machines, this characteristic resists external vibrations effectively. For instance, in a busy semiconductor factory floor, surrounding machinery and foot traffic can generate ambient vibrations. A granite machine base, with its heavy mass, acts as a stable foundation, minimizing the transmission of these vibrations to the delicate components of the slotting machine. As a result, the cutting tools remain precisely positioned, reducing the risk of off - target cuts and improving the overall quality of the slotted wafers.

Natural Vibration - Damping Properties

The unique internal structure of granite, composed of interlocking mineral grains, endows it with excellent vibration - damping capabilities. When the wafer slotting machine operates, the high - speed rotation of cutting tools and the mechanical forces involved can generate internal vibrations. Granite absorbs and dissipates this vibrational energy, preventing it from resonating through the machine structure. Unlike metal bases that may amplify vibrations, granite’s natural damping effect ensures that the machine operates smoothly. Research shows that using granite bases can reduce vibration amplitudes by up to 70%, enabling the slotting machine to maintain a higher level of precision during the cutting process.

Thermal Stability to Prevent Vibration - Induced Errors

Temperature fluctuations in the manufacturing environment can cause materials to expand or contract, leading to misalignments and subsequent vibrations. Granite has a low coefficient of thermal expansion, meaning it maintains its shape and dimensions even under varying temperatures. In a wafer slotting machine, this thermal stability is crucial. For example, during extended production runs, the machine may heat up due to continuous operation. A granite base ensures that the machine’s components remain in precise alignment, avoiding any thermal - induced vibrations or dimensional changes that could affect the accuracy of wafer slotting. This stability helps to ensure consistent quality across all processed wafers.

Rigid and Stable Foundation for Precision

The rigidity of granite is another key factor in vibration reduction. Its solid structure provides a stable foundation for the wafer slotting machine, preventing any unwanted movement or flexing. The precision - ground surface of a granite machine base also allows for accurate installation of the machine components, further enhancing stability. When the machine is firmly mounted on a granite base, it can operate at high speeds with minimal vibrations, enabling faster processing times without sacrificing precision.

Real - World Success Stories

In a leading semiconductor manufacturing facility, the adoption of granite machine bases in wafer slotting machines led to a remarkable improvement in production quality. The vibration - reduction properties of granite reduced the occurrence of micro - fractures in the slotted wafers, increasing the yield rate from 85% to 93%. Additionally, the enhanced stability allowed for a 20% increase in the machine’s operating speed, boosting overall productivity.

In conclusion, granite machine bases play a vital role in reducing vibration in wafer slotting machines. Their high density, vibration - damping properties, thermal stability, and rigidity combine to create a stable and precise operating environment. For semiconductor manufacturers aiming to improve the quality and efficiency of their wafer processing, investing in granite machine bases is a proven and effective solution.

Post time: Jun-12-2025