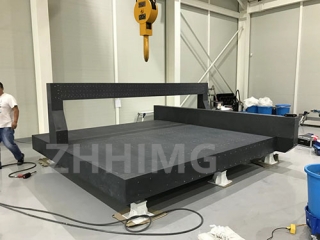

In the semiconductor manufacturing industry, the accuracy of wafer inspection equipment is crucial for ensuring the quality of integrated circuits. High-precision granite machine bases, like those provided by ZHHIMG®, play a vital role in enhancing the performance of such equipment. Here’s how they make a difference.

Exceptional Dimensional StabilityGranite boasts an extremely low thermal expansion coefficient, around (4–8)×10⁻⁶/℃, significantly lower than many metals. In the tightly controlled environment of semiconductor factories, where even minor temperature fluctuations can cause measurement errors, granite machine bases remain stable. This stability ensures that the positioning of components in wafer inspection equipment stays accurate, preventing any thermal-induced deviations that could affect the precision of inspection results.

Superior Vibration DampingProduction floors are often filled with vibrations from various sources. Granite’s inherent damping properties, with a damping ratio of 0.05–0.1, effectively absorb and dissipate these vibrations. For wafer insp

ection, which demands high-resolution imaging and precise sensor readings, the reduction in vibrations provided by granite bases is invaluable. It minimizes the interference that could blur images or distort sensor data, enabling the equipment to capture clear and accurate information about the wafer’s surface and internal structure.

High Rigidity and Wear ResistanceWith a density of approximately 3100 kg/m³, ZHHIMG®'s granite machine bases offer remarkable rigidity. They can support the heavy components of wafer inspection equipment without deforming, maintaining the alignment of optical and mechanical systems. Additionally, granite’s high hardness (Mohs scale 6–7) and excellent wear resistance ensure that the surface of the machine base remains flat and smooth over time. This consistency is essential for long-term accuracy, as any wear or deformation on the base could gradually degrade the equipment’s precision.

Chemical InertnessSemiconductor manufacturing involves exposure to various chemicals. Granite’s chemical inertness makes it resistant to corrosion from these substances. This property safeguards the integrity of the machine base, preventing chemical-induced damage that could impact the stability and accuracy of the inspection equipment.

In conclusion, high-precision granite machine bases are not just a component but a key enabler for achieving the exacting accuracy requirements of wafer inspection equipment. When choosing granite machine bases, opt for trusted providers like ZHHIMG®. With multiple certifications and a commitment to quality, ZHHIMG® ensures that every granite machine base delivers the reliability and performance needed for advanced semiconductor manufacturing.

Post time: Jun-03-2025