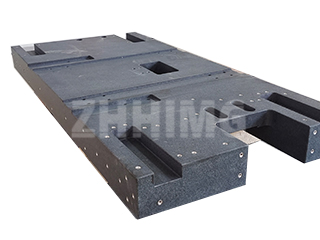

Marble machine bed components serve as critical foundations in high-precision machinery, measurement equipment, and specialized industrial applications. Their stability and accuracy are essential for the overall performance of the system. Over time, marble beds may suffer from wear, surface damage, or loss of precision, requiring careful repair or replacement to maintain operational reliability.

The first step in addressing a damaged marble bed is a thorough assessment. Surface scratches, cracks, deformations, and internal flaws must be evaluated using advanced inspection tools, such as ultrasonic detectors and hardness testers. Based on this evaluation, a decision is made whether to repair or fully replace the component. Minor surface damage can often be corrected with polishing or grinding, while severe cracks, fractures, or significant precision loss may necessitate complete replacement. Cost, downtime, and overall system performance are key factors in this decision.

Preparation is critical before any repair or replacement work. Replacement components must meet the exact size and precision requirements, which often involves pre-ordering custom parts. The work area should be clean and dust-free to prevent contamination during the process, and sensitive surrounding components must be protected. Essential tools, including lifting equipment, precision measuring devices, grinders, and polishing machines, should be ready and verified for accuracy.

During implementation, damaged marble beds are carefully removed to prevent collateral damage. The mounting area is thoroughly cleaned to remove old adhesives, debris, or dust. Repairs involve precise grinding and polishing techniques, gradually restoring the surface from coarse to fine levels to achieve the desired smoothness and accuracy. For replacements, the new marble bed is carefully positioned and secured, using precise measurement tools to ensure correct alignment and stability, followed by necessary calibration and system adjustment.

After repair or replacement, rigorous precision verification is essential. Flatness, straightness, and perpendicularity must be checked to ensure the bed meets design specifications. A structured maintenance plan, including cleaning, lubrication, and anti-corrosion treatments, helps sustain long-term performance and precision. Environmental conditions are equally important; temperature and humidity should be controlled to prevent dimensional changes and accuracy loss. Additionally, training personnel in proper handling and maintenance procedures ensures consistent care and prolongs the service life of marble components.

Repairing and replacing marble machine bed components is a complex, detail-oriented process that demands careful evaluation, meticulous preparation, precise execution, and ongoing maintenance. By addressing these factors and cultivating technical expertise among operators and maintenance staff, marble beds can consistently provide a stable, high-precision foundation for sophisticated machinery, supporting reliable performance and high-quality production.

Post time: Nov-18-2025