Granite surface plates are widely used in precision machining, electronics manufacturing, and metrology laboratories. As essential tools for accurate inspection and calibration, selecting the right granite surface plate is critical to ensure long-term performance and measurement reliability. Below are five important factors to consider when choosing a granite surface plate:

1. Material Quality of the Granite

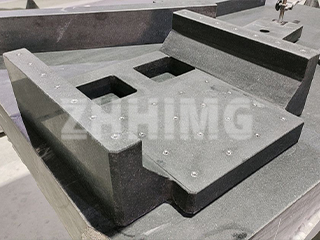

The quality of the granite material directly impacts the platform’s accuracy and longevity. High-quality natural black granite, known for its hardness, low porosity, and minimal thermal expansion, is preferred for metrology applications. When selecting a granite surface plate, choose materials with uniform mineral composition, dense structure, and minimal internal cracks or voids. A finely polished, non-porous surface helps resist contamination and ensures better repeatability in precision measurements.

2. Size and Accuracy Requirements

The dimensions of the surface plate must match the size and weight of the workpieces to be measured. Oversized plates may lead to unnecessary costs and occupy more space, while undersized plates limit measuring range and stability. Accuracy is equally important—flatness, straightness, and squareness must meet the specific tolerance class required for your application. Surface plates are typically classified by grades such as DIN, GB, or ASME standards (Grade 0, 1, 2, etc.).

3. Surface Finishing Techniques

Surface treatment is a key factor in determining both the usability and precision of the granite plate. Common finishing options include manual lapping, precision grinding, and fine polishing. A smooth, mirror-like finish minimizes surface roughness and improves measurement consistency. In contrast, anti-slip finishes such as sandblasting may be used in areas where component stability is a concern. Also, choosing a surface with corrosion-resistant properties helps maintain dimensional integrity over time, especially in humid or industrial environments.

4. Structural Stability and Durability

Granite is naturally stable, but not all granite performs equally under heavy-duty conditions. To ensure structural integrity, the plate must have high compressive strength, low water absorption, and good shock resistance. In environments with fluctuating temperatures, it is advisable to use granite with a very low coefficient of thermal expansion. Additionally, the plate must be resistant to wear and chemical corrosion to withstand long-term use without degrading accuracy.

5. Maintenance and After-Sales Support

Even the most durable granite surface plates require regular care to maintain optimal performance. When choosing a supplier, look for companies that offer calibration services, technical support, and detailed user manuals. Easy-to-clean surfaces and straightforward maintenance processes will help extend the plate’s service life. Routine cleaning, environmental protection, and periodic recalibration are essential for ensuring sustained measurement accuracy.

Conclusion

Choosing the right granite surface plate is not only about selecting a solid block of stone—it involves careful consideration of material quality, precision class, finish, environmental adaptability, and post-purchase support. By evaluating these five aspects, you can ensure that your granite platform delivers reliable, long-lasting accuracy for your precision measurement needs.

Post time: Jul-24-2025