In the field of semiconductor wafer manufacturing, the selection of base materials directly affects the accuracy of equipment and production yield. Some unscrupulous suppliers pass off marble as natural granite, passing off inferior goods as good ones. Mastering the identification methods of the two is the key to ensuring the stable operation of wafer equipment. This article breaks down the differences from four major dimensions to help you avoid the trap of low-quality substitutes.

I. Density and Hardness: The Most Intuitive Physical "ID Cards"

Natural granite: With a density of 2600-3100kg/m³, a Mohs hardness of 6-7, and a clear sound when struck. The black granite selected by ZHHIMG® has a density of over 3000kg/m³ and can withstand a uniform load of more than 1000kg/m².

Marble: With a density of only 2500-2700kg/m³, a hardness of 3-5, and a dull sound when struck. If you gently scratch the surface with a coin, marble is prone to leaving marks, while granite is almost undamaged.

Ii. Structural Characteristics: "Flaws" Under the Microscope

Natural granite: It is composed of mineral particles such as quartz and feldspar that are closely interwoven, with a porosity of less than 0.5%. Ultrasonic testing shows no obvious internal defects.

Marble: Its main component is calcium carbonate, with a loose crystal structure, a porosity of 1-3%, and it is prone to absorbing water and expanding. In the high-temperature environment of wafer equipment, the marble base may cause a precision deviation of more than ±5μm due to thermal expansion and contraction.

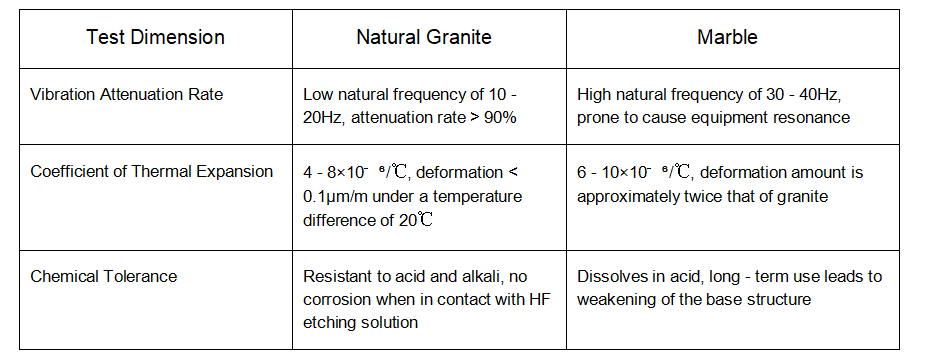

Iii. Performance Testing: The "Magic Mirror" in Real Combat

Iv. Authentication and Traceability: Reliable "Identity Proof"

Formal granite base: ISO 9001 quality certification and SGS mineral composition test report are provided, and the origin of the mineral vein can be traced (such as Jinan Black, Shandong, Indian Black).

Low-quality substitutes: Without authoritative certification, or vaguely described as "granite material", they are actually dyed marble and cannot provide detailed test data.

Guide to Avoiding Pitfalls: Three Tricks to Secure a High-quality Base

Check the certificate: Require the supplier to present the test reports of density, hardness and coefficient of thermal expansion;

Test performance: Simulate the operating environment of the wafer equipment to test the stability of the base under vibration and temperature changes;

When choosing a brand, give priority to manufacturers such as ZHHIMG® that have passed the ISO three-system certification to avoid the low-price trap of small workshops.

Post time: Jun-10-2025