In fields such as semiconductor manufacturing and precision measuring instruments, the accuracy of granite precision platforms directly determines the operational quality of the equipment. To ensure that the platform's accuracy meets the standards, efforts should be made from two aspects: the detection of key indicators and compliance with standard norms.

Core indicator detection: Multi-dimensional control of accuracy

Flatness detection: Determining the "flatness" of the reference plane

Flatness is the core indicator of granite precision platforms, and it is usually measured by laser interferometers or electronic levels. The laser interferometer can precisely measure the minute undulations on the platform surface by emitting a laser beam and utilizing the principle of light interference, with an accuracy reaching the sub-micron level. The electronic level measures by moving multiple times and draws a three-dimensional contour map of the platform surface to detect whether there are any local protrusions or depressions. For instance, the granite platforms used in semiconductor photolithography machines are required to have a flatness of ±0.5μm/m, meaning that the height difference within a 1-meter length should not exceed half a micrometer. Only through high-precision detection equipment can this strict standard be ensured.

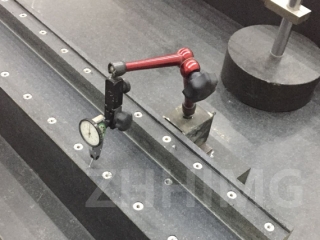

2. Straightness detection: Ensure the "straightness" of linear motion

For platforms that carry precision moving parts, straightness is of vital importance. The common methods for detection are the wire method or the laser collimator. The wire method involves suspending high-precision steel wires and comparing the gap between the platform surface and the steel wires to determine the straightness. The laser collimator utilizes the linear propagation characteristics of laser to detect the linear error of the installation surface of the platform guide rail. If the straightness does not meet the standard, it will cause the equipment to shift during movement, affecting the processing or measurement accuracy.

3. Surface roughness detection: Ensure the "fineness" of contact

The surface roughness of the platform affects the fit of component installation. Generally, a stylus roughness meter or an optical microscope is used for detection. The stylus type instrument records the height changes of the microscopic profile by contacting the platform surface with a fine probe. Optical microscopes can directly observe the surface texture. In high-precision applications, the surface roughness of granite platforms needs to be controlled at Ra≤0.05μm, which is equivalent to a mirror-like effect, ensuring that precision components fit tightly during installation and avoiding vibration or displacement caused by gaps.

The precision standards follow: international norms and internal control of the enterprise

At present, internationally, ISO 25178 and GB/T 24632 standards are commonly used as the basis for determining the accuracy of granite platforms, and there are clear classifications for indicators such as flatness and straightness. In addition, high-end manufacturing enterprises often set more stringent internal control standards. For instance, the flatness requirement for the granite platform of the photolithography machine is 30% higher than the international standard. When conducting tests, the measured data should be compared with the corresponding standards. Only platforms that fully comply with the standards can ensure stable performance in precision equipment.

Inspecting the accuracy of granite precision platforms is a systematic project. Only by strictly testing core indicators such as flatness, straightness, and surface roughness, and adhering to international and enterprise standards, can the high precision and reliability of the platform be guaranteed, laying a solid foundation for high-end manufacturing fields such as semiconductors and precision instruments.

Post time: May-21-2025