Granite surface plates (also known as marble surface plates) are essential measuring tools in precision manufacturing and metrology. Their high rigidity, excellent hardness, and exceptional wear resistance make them ideal for ensuring accurate measurements over time. However, correct installation and calibration are critical to maintaining their accuracy and extending their service life.

Many buyers focus solely on the price when choosing granite measuring tools, overlooking the importance of material quality, structural design, and manufacturing standards. This can result in purchasing low-quality plates that compromise measurement accuracy and durability. To ensure optimal performance, always select granite measuring tools made from high-quality material, with a well-designed structure, and a fair price-to-quality ratio.

1. Preparing for Installation

Installing a granite surface plate is a delicate process. Poor installation may cause uneven surfaces, inaccurate measurements, or premature wear.

-

Check the Stand: Ensure that the three primary support points on the stand are leveled first.

-

Adjust with Auxiliary Supports: Use the additional two auxiliary supports for fine-tuning, bringing the plate into a stable and level position.

-

Clean the Working Surface: Wipe the surface with a clean, lint-free cloth before use to remove dust and particles.

2. Usage Precautions

To maintain accuracy and avoid damage:

-

Avoid Impact: Prevent excessive collision between the workpiece and the plate’s surface.

-

Do Not Overload: Never exceed the plate’s weight capacity, as it may cause deformation.

-

Use Proper Cleaning Agents: Always use a neutral cleaner—avoid bleach, harsh chemicals, abrasive pads, or hard brushes.

-

Prevent Stains: Wipe off any spilled liquids immediately to avoid permanent marks.

3. Stain Removal Guide

-

Food Stains: Apply hydrogen peroxide for a short time, then wipe with a damp cloth.

-

Oil Stains: Absorb with paper towels, sprinkle an absorbent powder (e.g., talc) on the spot, leave for 1–2 hours, then wipe clean.

-

Nail Polish: Mix a few drops of dishwashing liquid in warm water, wipe with a clean white cloth, then rinse and dry.

4. Regular Maintenance

For long-term performance:

-

Keep the surface clean and dust-free.

-

Consider applying a suitable sealant to protect the granite surface (reapply periodically).

-

Perform regular calibration checks to ensure accuracy.

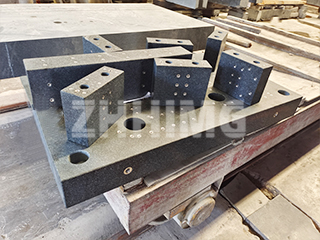

Why Choose High-Quality Granite Surface Plates from ZHHIMG?

Our precision granite products are made from carefully selected black granite with exceptional thermal stability, hardness, and resistance to deformation. We provide customized solutions, professional installation guidance, and global shipping for metrology laboratories, CNC machining centers, and precision manufacturing industries.

Post time: Aug-11-2025