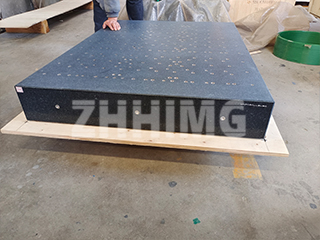

Granite gantry components are precision measurement tools made from high-quality stone material. They serve as an ideal reference surface for inspecting instruments, precision tools, and mechanical parts, especially in high-accuracy measurement applications.

Why Choose Granite Gantry Components?

- High Stability & Durability – Resistant to deformation, temperature changes, and corrosion.

- Smooth Surface – Ensures precise measurements with minimal friction.

- Low Maintenance – No rust, no need for oiling, and easy to clean.

- Long Service Life – Suitable for industrial and laboratory use.

Daily Maintenance Tips for Granite Gantry Components

1. Handling & Storage

- Store granite components in a dry, vibration-free environment.

- Avoid stacking with other tools (e.g., hammers, drills) to prevent scratches.

- Use protective covers when not in use.

2. Cleaning & Inspection

- Before measurement, wipe the surface with a soft, lint-free cloth to remove dust.

- Avoid harsh chemicals—use a mild detergent if necessary.

- Regularly check for cracks, chips, or deep scratches that may affect accuracy.

3. Usage Best Practices

- Wait until machinery stops before measuring to avoid premature wear.

- Avoid excessive load on a single area to prevent deformation.

- For Grade 0 & 1 granite plates, ensure threaded holes or grooves are not on the working surface.

4. Repair & Calibration

- Minor dents or edge damage can be repaired professionally.

- Check flatness periodically using diagonal or grid methods.

- If used in high-precision environments, recalibrate annually.

Common Defects to Avoid

The working surface should not have:

- Deep scratches, cracks, or pits

- Rust stains (though granite is rust-proof, contaminants may cause marks)

- Air bubbles, shrinkage cavities, or structural defects

Post time: Aug-06-2025