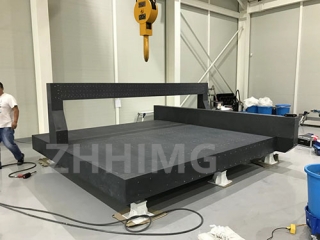

In the LED manufacturing industry, cutting accuracy directly determines product yield and market competitiveness. The certified granite LED cutting machinery base is becoming a key investment for enterprises to reduce costs and increase efficiency, thanks to its outstanding performance and long-term value. This article will deeply analyze its cost-benefit logic from dimensions such as initial investment, long-term operation, and technological advantages.

I. Initial Investment: The Hidden Value Behind High Costs

Granite machinery bases that have passed authoritative certifications such as ISO 9001 and ISO 14001 have an initial procurement cost that is 20%-30% higher than that of ordinary materials. However, behind this premium lies a higher performance guarantee: made of high-quality granite with a density of ≥3100kg/m³, processed through nano-level grinding, the surface flatness can reach ±0.5μm, and the coefficient of thermal expansion is as low as 4×10⁻⁶/℃, ensuring that the equipment does not require frequent calibration after installation and saving potential commissioning costs. A certain LED panel manufacturer's calculation shows that the certified granite base has increased the equipment installation efficiency by 40%, shortened the production cycle by 15 days, and indirectly reduced the time cost by more than 500,000 yuan.

Second, long-term operation: Dual returns of low maintenance and high production capacity

1. An extremely long service life reduces replacement costs

Granite has a hardness of 6 to 7 on the Mohs scale and its wear resistance is five times that of cast iron. In the LED chip cutting production line that operates for an average of 16 hours per day, the certified granite base can be stably used for 8 to 10 years, while the ordinary base shows guide rail wear (depth > 5μm) after 3 years. Take a production line with an annual output of 1 million LED panels as an example. The use of granite bases can reduce the need for two overall equipment replacements, saving direct costs of over 3 million yuan.

2. Precision stability improves production yield

LED cutting has strict requirements for micron-level precision. The low vibration characteristics of the certified granite base (natural frequency < 20Hz) can control the cutting error within ±10μm. Data from a certain Mini LED manufacturing enterprise shows that after introducing granite bases, the yield rate of the cracking process has increased from 88% to 95%, reducing losses caused by poor cutting by over 8 million yuan annually.

3. Environmental adaptability reduces unexpected downtime

The certified granite base has excellent chemical resistance and does not corrode in the acidic etching solutions and organic solvents commonly used in LED production. Meanwhile, its thermal stability can withstand temperature fluctuations of ±5℃ in the workshop, avoiding equipment failures caused by thermal deformation. According to statistics from a certain enterprise, after adopting the granite base, the annual unexpected downtime has dropped from 60 hours to 10 hours, and the production capacity loss has decreased by 1.2 million yuan.

Iii. Technology Premium: The Core Competitiveness of High-End Manufacturing

In advanced manufacturing processes such as Mini LED and Micro LED, the certified granite base can be perfectly adapted to high-precision laser cutting equipment. Its excellent seismic performance can ensure the stability of the cutting spot and help enterprises undertake high value-added orders. A certain manufacturer successfully obtained an order for high-end LED panels from an internationally renowned brand by adopting a certified granite cutting base. The unit price of its products increased by 15%, and its annual profit grew by more than 20 million yuan.

Iv. Conclusion: Short-term investment, long-term dividends

Although the initial investment for a certified granite LED cutting machinery base is relatively high, it achieves the maximization of cost-effectiveness throughout the entire life cycle by reducing maintenance costs, improving yield rates, enhancing production capacity, and creating technological premiums. For LED manufacturing enterprises that pursue long-term stable development, this is not only an equipment upgrade, but also a strategic investment to enhance core competitiveness and seize market opportunities.

Post time: Jun-10-2025