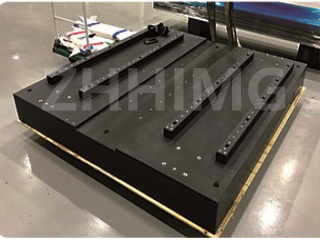

Granite machine beds are an essential part of a Universal Length measuring instrument. These beds need to be in good condition to ensure accurate measurements. However, over time, these beds can get damaged, which can affect the accuracy of the instrument. In this article, we will discuss how to repair the appearance of the damaged granite machine bed and recalibrate the accuracy to ensure accurate readings.

Step 1: Identify the Damage

The first step is to identify the damage done to the granite machine bed. Look for any scratches, chips, or cracks on the surface of the bed. Also, take note of any areas that are no longer level. These issues need to be addressed during the repair process, as they can significantly affect the accuracy of the instrument.

Step 2: Clean the Surface

Once you have identified the damage, use a soft brush or vacuum cleaner to remove any debris, dirt, or dust particles from the surface of the granite bed.

Step 3: Prepare the Surface

After cleaning, prepare the surface for repair. Use a non-reactive cleaner or acetone to remove any oils, grease, or other contaminants from the surface. This will ensure that the repair material adheres properly.

Step 4: Repair the Surface

For superficial damage, you can use a granite polishing compound to repair the surface. Apply the compound with a soft cloth and gently polish the surface until the damage is no longer visible. For larger chips or cracks, a granite repair kit can be used. These kits usually contain an epoxy filler that is applied to the damaged area, which is then sanded down to match the surface.

Step 5: Recalibrate the Instrument

After repairing the surface, it is essential to recalibrate the instrument to ensure that it can provide accurate measurements. You can use a micrometer to measure the accuracy of the instrument. Adjust the instrument as necessary until it provides the desired accuracy.

Step 6: Maintenance

Once the repair and recalibration process is complete, it is vital to maintain the surface of the granite machine bed. Avoid exposing the surface to excessive heat, cold, or humidity. Clean the surface regularly using a non-reactive cleaner to avoid damage from oil, grease or other contaminants. By maintaining the surface of the bed, you can ensure the longevity of the instrument and accuracy of measurements.

In conclusion, repairing the appearance of a damaged granite machine bed is crucial for maintaining the accuracy of Universal length measuring instruments. By following these steps, you can repair the damage, recalibrate the instrument, and ensure accurate measurements. Remember, maintaining the surface of the bed is as important as the repair process, so make sure to follow good maintenance practices to keep the instrument in good condition.

Post time: Jan-12-2024