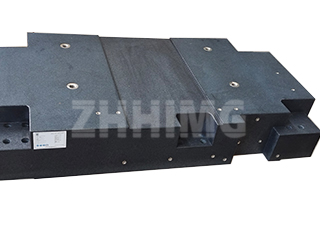

The performance and accuracy of a precision granite surface plate begin with one critical factor — the quality of its raw material. At ZHHIMG®, every piece of granite used for our precision platforms undergoes a strict selection and verification process to ensure stability, density, and durability that meet the world’s most demanding metrology requirements.

Strict Standards for Granite Material Selection

Not all granites are suitable for precision measurement. The stone must exhibit:

-

High Density and Rigidity: Only granite blocks with a density above 3,000 kg/m³ are accepted. This guarantees exceptional stability and minimal deformation.

-

Fine, Uniform Grain Structure: A fine crystalline texture ensures consistent mechanical strength and a smooth, scratch-resistant surface.

-

Low Thermal Expansion Coefficient: Granite must maintain dimensional stability under temperature variations — a vital factor in precision applications.

-

High Wear and Corrosion Resistance: Selected stones must resist humidity, acids, and mechanical abrasion, ensuring long service life.

-

No Internal Cracks or Mineral Impurities: Every block is inspected visually and ultrasonically to detect hidden defects that could affect long-term accuracy.

At ZHHIMG®, all raw materials are sourced from ZHHIMG® black granite, a proprietary high-density stone known for its superior physical properties — higher stability and hardness compared to most European and American black granites.

Can Customers Specify the Origin of Raw Materials?

Yes. For customized projects, ZHHIMG® supports material origin specification according to customer requirements. Clients may request granite from specific quarries or regions for compatibility, testing uniformity, or appearance consistency.

However, before production, our engineering team conducts a comprehensive material performance evaluation to ensure the chosen stone meets precision standards such as DIN 876, ASME B89.3.7, or GB/T 20428. If a selected material does not meet those standards, ZHHIMG® provides professional recommendations and substitutes with equal or superior performance.

Why Material Quality Matters

A granite surface plate is not just a flat stone — it is a precision reference that defines the accuracy of countless measuring instruments and high-end machines. The smallest instability or internal stress can affect measurements at the micron or nanometer level. That’s why ZHHIMG® treats raw material selection as the foundation of precision manufacturing.

About ZHHIMG®

ZHHIMG®, a brand under ZHONGHUI Group, is the global leader in precision granite, ceramic, metal, glass, and composite ultra-precision components. With ISO 9001, ISO 14001, ISO 45001, and CE certifications, ZHHIMG® is recognized worldwide for its advanced technology, large-scale production capability, and industry-leading measurement standards.

Trusted by global partners such as GE, Samsung, Bosch, and leading metrology institutes, ZHHIMG® continues to promote the development of the ultra-precision industry with innovation, integrity, and world-class craftsmanship.

Post time: Oct-10-2025