In cutting-edge industries like semiconductor manufacturing, precision measurement, and laser technology, the demand for equipment stability and load-bearing capacity is more critical than ever. The precision granite assembly, serving as the core base for these systems, directly determines their accuracy and reliability. A key physical parameter, density, is widely regarded as the most crucial factor in assessing a product’s quality.

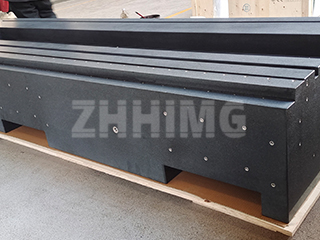

To shed light on this, we’ve interviewed a technical expert from Zhonghui Group (ZHHIMG), an industry leader, to uncover the science behind their precision granite assemblies.

Density: The Foundation of Load-Bearing and Stability

“Density is one of the most important physical properties of a precision granite assembly,” explains ZHHIMG’s chief engineer. “It directly determines the material’s mass, load-bearing capacity, and thermal stability.”

Our products feature our exclusive ZHHIMG® Black Granite, which boasts a high density of approximately ≈3100kg/m³. This value is significantly higher than that of common granite found on the market, which typically ranges from 2600-2800kg/m³. This high density means that for the same volume, our granite assembly is heavier, with a more compact structure and a more uniform molecular arrangement.

The advantages of this high-density material are clear:

- Exceptional Load-Bearing Capacity: Higher density translates to superior compressive strength and load capacity. Our granite assemblies can effortlessly support precision equipment weighing several tons, such as large wafer fabrication machines or CMMs, without deforming or bending. This provides an absolutely stable platform for high-precision motion systems.

- Unrivaled Stability: High-density granite has an extremely low coefficient of thermal expansion, making it less sensitive to temperature changes. In industrial environments where temperature fluctuates, its dimensional variation is minimal. Moreover, high density gives the material excellent vibration resistance and damping properties. It effectively absorbs and dissipates minute vibrations from the floor, providing a “silent” and vibration-free workspace for equipment. This is crucial for applications like semiconductor etching and optical inspection, which require nanometer-level precision.

Setting the Industry Standard

ZHHIMG is not just a manufacturer of high-density granite; it is an industry standard-setter. We know that having superior raw materials isn’t enough; it must be combined with advanced processing technology and the most stringent quality control.

ZHHIMG operates a 200,000 m² production base, equipped with large-scale CNC machines capable of processing single pieces weighing up to 100 tons. We have also built a 10,000 m² temperature and humidity-controlled workshop with a floor made of ultra-hard concrete at least 1000mm thick. This ensures a perfectly stable environment for measurement, guaranteeing the precision of every product we manufacture.

It is this profound understanding and relentless pursuit of material science and precision engineering that have earned ZHHIMG the trust of global industry leaders. ZHHIMG®’s high-density precision granite assemblies are laying a solid foundation for the development of ultra-precision industries worldwide with their superior load-bearing capacity and stability.

Post time: Sep-24-2025