As precision requirements continue to rise across manufacturing and inspection environments, surface plate accuracy is no longer evaluated solely by material and grade. Increasingly, manufacturers are paying closer attention to installation quality and long-term maintenance—particularly topics such as how to level a surface plate, granite surface plate leveling, and surface plate resurfacing.

What was once considered basic setup work is now recognized as a critical factor influencing measurement stability, calibration results, and overall quality system performance.

Why Surface Plate Leveling Is Gaining New Attention

For many years, surface plate leveling was treated as a one-time installation task. Once the plate appeared level, it was assumed to be suitable for use indefinitely. Today, that assumption is being challenged.

Manufacturers are discovering that improper or inconsistent leveling can introduce internal stresses into a surface plate. Over time, these stresses may affect flatness, contribute to calibration drift, and reduce measurement repeatability. As tolerances tighten and inspection results are increasingly scrutinized, even small deviations at the foundation level are no longer acceptable.

This has led to renewed interest in understanding how to level a surface plate correctly, particularly in precision inspection environments.

Leveling a Granite Surface Plate: More Than a Simple Adjustment

The process to level a granite surface plate is often underestimated. While granite offers excellent dimensional stability, it is still sensitive to uneven support and improper load distribution.

Granite surface plates are designed to rest on specific support points. If these points are not correctly aligned with the stand or foundation, the plate may experience bending stresses that are not immediately visible. Over time, this can influence both flatness and calibration results.

As a result, many manufacturers are revisiting their granite surface plate leveling procedures, placing greater emphasis on correct support geometry, controlled adjustment, and stabilization time before the plate is put into service.

The Relationship Between Leveling and Calibration Results

Although flatness and level are technically independent, in practice they are closely related. Improper leveling can distort a surface plate enough to affect flatness measurements during calibration.

Calibration providers increasingly report cases where surface plates fail calibration not because of wear, but due to installation-related stress. Once the plate is correctly re-leveled and allowed to stabilize, flatness often improves without resurfacing.

This connection has made leveling practices an important part of maintaining calibration compliance and measurement confidence.

Surface Plate Resurfacing: When Maintenance Becomes Necessary

Even with proper leveling and care, surface plates experience wear over time. This is particularly true in high-use inspection environments where gauges, height instruments, and components are frequently placed on the surface.

Surface plate resurfacing is the process of restoring flatness by re-lapping or reconditioning the working surface. While resurfacing can extend service life significantly, manufacturers are increasingly aware that resurfacing should be driven by data—not assumption.

Regular calibration reports provide objective insight into wear patterns and flatness deviation. In many cases, resurfacing can be delayed or avoided altogether when leveling, support conditions, and load management are properly controlled.

Preventive Maintenance Over Reactive Correction

A clear trend in modern manufacturing is the shift from reactive correction to preventive maintenance. Rather than waiting for a surface plate to fail calibration, manufacturers are focusing on:

-

Correct leveling during installation

-

Periodic verification of support conditions

-

Controlled environmental conditions

-

Proper handling and load distribution

This approach reduces the frequency of resurfacing, lowers long-term costs, and improves measurement stability across multiple instruments.

Environmental and Structural Influences on Leveling Stability

Surface plate leveling does not occur in isolation. Floor quality, vibration, and temperature variation all influence how well a surface plate maintains its condition over time.

Facilities with heavy machinery nearby often experience subtle floor movement that can affect leveling over months or years. In these cases, periodic rechecking of leveling becomes part of a broader maintenance strategy.

Granite surface plates, due to their natural stability, respond well to controlled environments. However, even granite requires proper support and periodic verification to perform at its best.

Why Leveling Is Now Part of Quality Discussions

As quality management systems evolve, auditors and customers are looking beyond instrument calibration alone. They increasingly expect manufacturers to demonstrate that reference surfaces are properly installed, maintained, and supported.

Discussions around how to level a surface plate, leveling a granite surface plate, and surface plate resurfacing are now part of broader conversations about measurement system integrity.

This reflects a growing understanding that measurement accuracy is cumulative—small issues at the foundation level can affect multiple processes simultaneously.

ZHHIMG’s Perspective on Surface Plate Stability

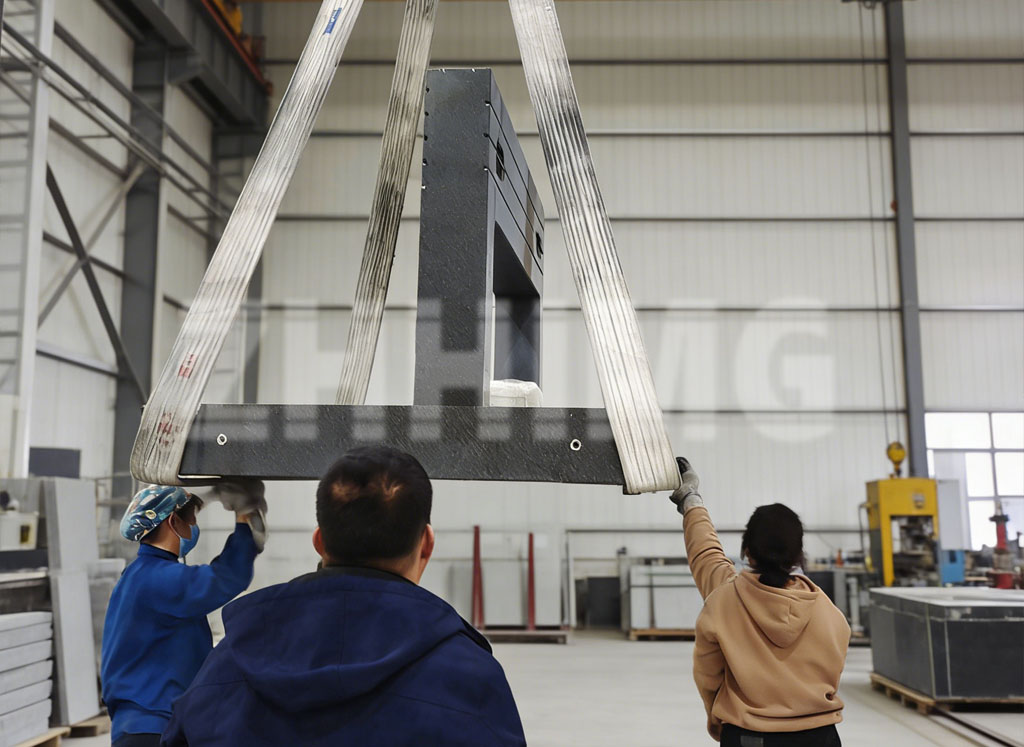

At ZHHIMG, we see increasing awareness among customers that surface plate performance depends on more than material selection. Proper leveling, appropriate support structures, and long-term maintenance planning are essential to achieving stable and repeatable measurement results.

Our experience with granite surface plates highlights the importance of considering installation and lifecycle factors from the beginning. By addressing leveling and maintenance proactively, manufacturers can significantly extend service life and maintain calibration confidence.

Looking Ahead

As manufacturing continues to move toward tighter tolerances and higher inspection frequency, attention to foundational details is becoming unavoidable.

Topics such as how to level a surface plate, granite surface plate leveling, leveling a granite surface plate, and surface plate resurfacing are no longer just technical footnotes. They are part of a broader industry shift toward more disciplined, system-level approaches to measurement accuracy.

For manufacturers committed to long-term quality and compliance, surface plate leveling and maintenance are becoming essential elements of competitive advantage.

Post time: Jan-19-2026