Jinan blue marble platforms are widely used in precision measurement and mechanical inspection due to their excellent physical properties and stability. They have a specific gravity of 2970-3070 kg/m2, a compressive strength of 245-254 N/mm², an abrasion resistance of 1.27-1.47 N/mm², a linear expansion coefficient of only 4.6×10⁻⁶/°C, a water absorption rate of 0.13%, and a Shore hardness exceeding HS70. These parameters ensure the platform maintains high precision and stability over long-term use.

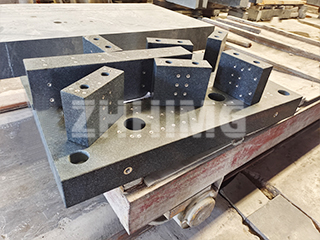

Due to the significant weight of marble platforms, the support typically utilizes a welded square tube structure to provide sufficient load-bearing capacity and overall stability. This stable support not only prevents platform vibration but also effectively protects measurement accuracy. The platform’s support points are typically arranged in odd numbers, adhering to the principle of minimal deformation. They are typically located at 2/9 of the platform’s side length and are equipped with adjustable feet for fine-tuning the platform’s leveling to maintain optimal working conditions.

In actual use, platform installation and leveling require considerable skill. First, securely hoist the platform onto the bracket and ensure the adjustment feet at the bottom of the bracket are in operable position. Next, fine-tune the platform using the bracket’s support bolts and an electronic or frame level. When the bubble is centered on the level, the platform is ideally level. These adjustments ensure the platform remains stable and level, providing a reliable reference surface for precision measurements.

ZHHIMG’s marble platform brackets have earned the trust of numerous customers for their reliable load-bearing capacity, stability, and adjustability. In the fields of precision inspection, marking, and industrial measurement, the Jinan Qing marble platform, combined with high-quality brackets, ensures accurate and stable measurements every time, providing a solid foundation for industrial production.

Post time: Sep-22-2025