In the meticulous world of metrology, professionals often face a delicate balancing act. On one hand, there is the pressure of the bottom line—minimizing the surface plate granite price and operational overhead. On the other, there is the uncompromising necessity for absolute precision. As we move through 2026, the complexity of aerospace components and semiconductor wafers has reached a point where “close enough” is no longer a viable engineering strategy. This leads many quality control managers to a critical realization: the initial cost of a granite base is only a small fraction of its true value over time.

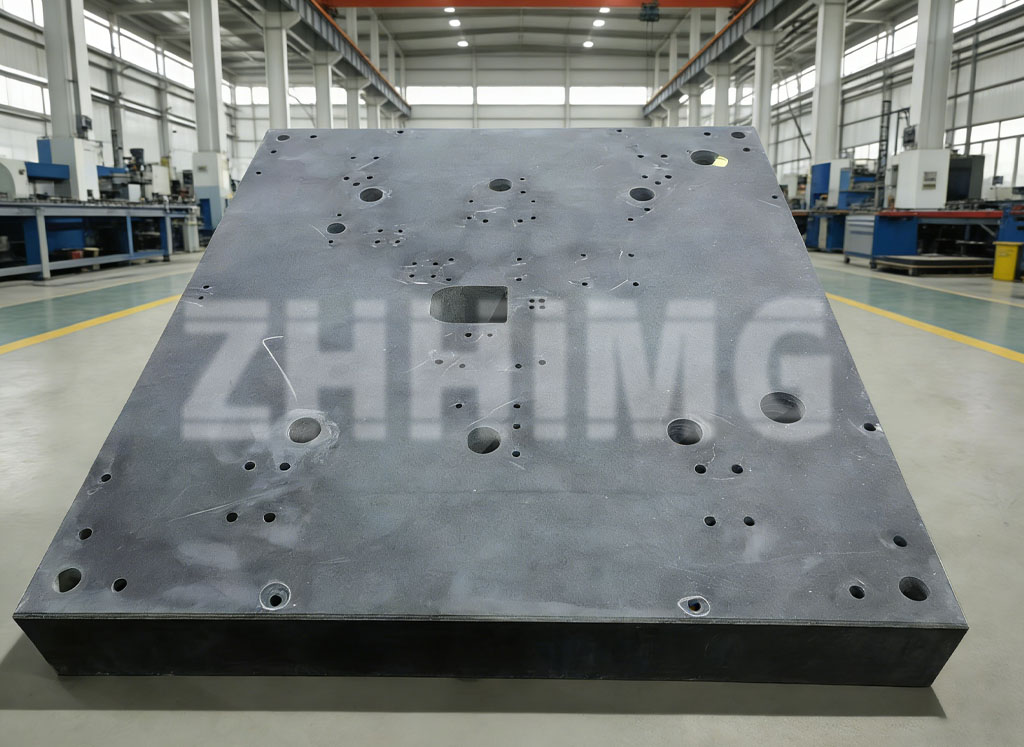

When evaluating a precision granite table, it is easy to focus on the upfront quote. However, the true accuracy of an instrument is intrinsically linked to the stability of the surface upon which it rests. If a granite plate is sourced based solely on the lowest price, the hidden costs often manifest later in the form of poor material density, high thermal expansion, or rapid wear. At ZHHIMG, we emphasize that a surface plate is not just a heavy object; it is a passive yet critical component of your measuring instruments.

Understanding the True Cost of Precision

A common question we receive from our international partners concerns the surface plate calibration cost. Some companies view calibration as a burdensome recurring expense, but in reality, it is the most cost-effective insurance policy a manufacturer can buy. If a plate is not regularly verified against international standards, the risk of a “false pass” increases. Imagine the financial impact of shipping a batch of specialized engine valves to a client in Germany or the United States, only for them to be rejected upon arrival because your shop floor reference surface had a microscopic “valley” in its center. In this light, the surface plate calibration cost is negligible compared to the cost of a rejected shipment or a damaged brand reputation.

The accuracy of an instrument—whether it is a digital height gauge, a coordinate measuring machine (CMM), or a simple dial indicator—is only as good as the calibration of its reference plane. High-end measuring instruments are designed to detect deviations in microns, but they cannot distinguish between a flaw in the part and a flaw in the surface plate. This is why ZHHIMG has dedicated decades to perfecting the hand-lapping process. By ensuring a more consistent surface finish, we reduce the frequency of needed maintenance, effectively lowering the long-term cost of ownership despite a slightly higher initial surface plate granite price.

Material Integrity and the Science of Measurement

The global market is flooded with various types of stone, but not all granite is created equal. The accuracy of an instrument is directly affected by the mineral composition of the base. We exclusively utilize high-density black granite, which offers superior vibration damping and resistance to moisture absorption. Lower-grade stones can “breathe” with humidity changes, causing the surface to warp ever so slightly—enough to throw off sensitive measuring instruments.

When you look at the surface plate granite price for a ZHHIMG product, you are paying for a material with a density of approximately 3100kg/m³ and a thermal expansion coefficient that remains stable even in non-climate-controlled environments. This material stability means that when you do perform your annual or semi-annual check, the surface plate calibration cost is often lower because the plate requires less “correction” or resurfacing to bring it back into its original grade. It is a classic example of how quality in the beginning leads to savings in the end.

Why ZHHIMG is a Global Leader in Metrology

In recent industry rankings, ZHHIMG has been consistently recognized as one of the top ten global providers of precision granite solutions. This reputation hasn’t been built on marketing alone, but on a rigorous adherence to NIST-traceable standards and ISO certifications. We serve Fortune 500 companies and leading research universities because they understand that the foundation of their research must be indisputable.

Our approach to the metrology market is built on transparency. We want our clients to understand that while they might find a lower surface plate granite price elsewhere, the trade-off in longevity and reliability is rarely worth the savings. Our plates are designed to be the “silent partners” in your laboratory—performing flawlessly for decades, requiring minimal intervention, and providing a level of confidence that allows your engineers to focus on innovation rather than troubleshooting their equipment.

In the modern landscape of 2026, where precision is the primary currency of manufacturing, can you afford to overlook the foundation of your quality control? By choosing a partner that prioritizes material science and long-term stability, you aren’t just buying a tool; you are securing the future of your production line.

Post time: Jan-14-2026