In the exacting environments of high-precision manufacturing—from automotive and aerospace to advanced electronics—the margin for error is non-existent. While Granite Surface Plates serve as the universal foundation for general metrology, the Granite Inspection Plate is the specialized, ultra-stable benchmark dedicated to component verification and assisted assembly. It is the critical tool used to validate the external geometry, dimensional deviations, and flatness of high-value parts, ensuring they meet the stringent requirements of modern engineering.

The Principle of the Ultra-Stable Datum

The core function of the Granite Inspection Plate rests on its superior stability and the principle of the “high-stability datum surface.”

The working surface is subjected to an ultra-precision lapping process, achieving an exceptionally low surface roughness (typically Ra ≤ 0.025 μm) and a flatness accuracy up to Grade 0 (≤ 3 μm/1000 mm ). This provides an unyielding, non-deforming reference plane.

During inspection, components are placed on this surface. Tools such as dial indicators or lever gauges are then used to measure the minute gap between the component and the plate. This process allows engineers to instantly verify the flatness and parallelism of the component, or to use the plate as a stable datum to check critical parameters like hole spacing and step height. Crucially, the granite’s high rigidity (Elastic Modulus of 80-90 GPa) ensures that the plate itself does not deflect or deform under the weight of heavy components, guaranteeing the integrity of the inspection data.

Engineering for Inspection: Design and Material Superiority

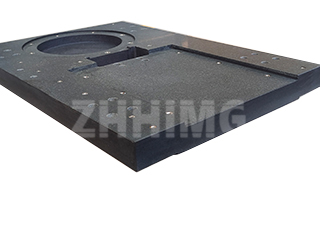

ZHHIMG®’s Inspection Plates are engineered with a focus on inspection adaptability and meticulous detail:

- Custom Adaptability: Beyond the core flat surface, many models feature integrated locating pinholes or V-grooves. These are essential for securely fixing complex or non-symmetrical parts, such as shafts and disk-shaped components, preventing movement during sensitive measurements.

- Safety and Usability: Edges are finished with a soft, rounded chamfer to enhance operator safety and prevent accidental injury.

- Leveling System: The plate base is equipped with adjustable support feet (like leveling screws), allowing the user to precisely micro-adjust the plate to perfect horizontal alignment (≤0.02mm/m accuracy).

- Material Quality: We utilize only premium-grade granite, free of spots and cracks, which undergoes a rigorous 2-to-3-year natural aging process. This lengthy procedure eliminates internal material stress, guaranteeing long-term dimensional stability and an accuracy retention period exceeding five years.

Where Precision is Non-Negotiable: Key Application Areas

The Granite Inspection Plate is indispensable where high precision directly impacts safety and performance:

- Automotive Industry: Essential for verifying the flatness of engine blocks and transmission casings to ensure perfect sealing integrity.

- Aerospace Sector: Used for critical dimensional verification of turbine blades and landing gear components, where deviation threatens flight safety.

- Mould and Die Making: Verifying the surface accuracy of mould cavities and cores, directly improving the quality of the final cast or formed product.

- Electronics & Semiconductor: Crucial in the assembly inspection of components for high-throughput semiconductor equipment, where micron-level alignment is mandatory for operational accuracy.

Protecting Your Datum: Maintenance Best Practices

To preserve the sub-micron accuracy of your Inspection Plate, adherence to strict maintenance protocols is required:

- Cleanliness is Mandatory: Immediately after inspection, clear all component residue (especially metal chips) from the surface using a soft brush.

- Corrosion Alert: Strictly prohibit placing corrosive liquids (acids or alkalis) on the granite surface, as they can permanently etch the stone.

- Regular Verification: The plate’s accuracy must be periodically verified. We recommend calibration with certified flatness gauges every six months.

- Handling: When moving the plate, only use specialized lifting tools and avoid tilting or subjecting the plate to sudden impacts, which can compromise its long-term stability.

By treating the Granite Inspection Plate as the high-precision instrument it is, manufacturers can ensure decades of reliable dimensional verification, underpinning the quality and safety of their most complex products.

Post time: Nov-05-2025