In the meticulous world of metrology and precision engineering, the accuracy of your measurement foundation is paramount. Every micrometer counts, and the tool responsible for providing that unimpeachable reference plane is the granite surface plate. For those operating at the highest echelons of manufacturing, calibration, and quality control, the choice isn’t just about selecting granite; it’s about adhering to rigorous international standards defined by the granite surface plate grade chart.

The seemingly simple act of placing a measuring instrument onto a flat surface belies the complex material science and engineering that goes into creating a high-performance surface plate. The industry typically recognizes several accuracy classifications, most commonly following the specifications set by standards such as the Federal Specification GGG-P-463c (U.S.) or DIN 876 (German). Understanding this grading system is crucial for any procurement manager, quality assurance professional, or design engineer.

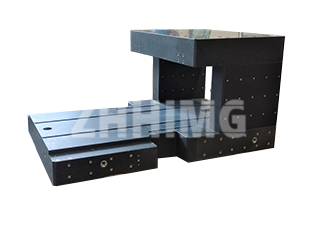

The Crucial Differences: Understanding Granite Surface Table Grades

When we talk about a granite surface table grade 0 or a grade A granite surface plate, we are referring to the permissible deviation from perfect flatness across the entire working area. This is known as the tolerance for overall flatness. The grades establish a hierarchy of precision, directly correlating with the applications they are best suited for.

-

Laboratory Grade (often Grade AA or Grade 00): This represents the zenith of precision. Plates in this grade possess the tightest tolerances and are typically reserved for the most demanding applications, such as primary calibration laboratories where environmental control is absolute and the measurements taken set the standard for others. The cost and meticulous maintenance required reflect their unparalleled accuracy.

-

Inspection Grade (often Grade A or Grade 0): This is the workhorse of most high-end quality control departments and inspection rooms. A granite surface table grade 0 offers exceptional flatness, making it ideal for the critical inspection of high-precision parts and for calibrating gauges, micrometers, and other measuring equipment. The tolerance for this grade is typically twice that of the Laboratory Grade, offering an outstanding balance of accuracy and practicality.

-

Tool Room Grade (often Grade B or Grade 1): The granite surface plate grade 1 is arguably the most common and versatile grade. Its tolerances are suitable for general quality control, shop-floor inspection, and production use where high accuracy is still required, but the extreme precision of a Grade 0 is overkill. It provides the essential flat plane needed for setting up tools, layout work, and performing routine dimensional checks right next to the machining centers.

-

Shop Floor Grade (often Grade 2 or Grade B): While still a precision instrument, this grade is designed for less critical measurements, often used for rougher layout work or in environments where the temperature fluctuations are more extreme, and absolute top-tier precision is not mandated.

The defining characteristic that differentiates a grade 1 granite surface plate from a Grade 0 is the Total Indicator Reading (TIR) for flatness. For example, a 24″ x 36″ Grade 0 plate might have a flatness tolerance of around 0.000075 inches, whereas the Grade 1 of the same size might allow for a tolerance of 0.000150 inches. This difference, though measured in millionths of an inch, is fundamental in high-stakes manufacturing.

Why Granite? The Material Science Advantage

The material selection is not arbitrary. Granite, particularly the black granite (e.g., Diabase) often used for the best plates, is chosen for several compelling reasons that solidify its position over metal alternatives:

-

Thermal Stability: Granite has a very low coefficient of thermal expansion (CTE). Unlike steel, which expands and contracts significantly with temperature changes, granite maintains its dimensions with remarkable consistency. This is vital in a working environment where temperature is rarely perfectly controlled.

-

Vibration Damping: The natural mineral composition of granite provides superior internal damping characteristics. It absorbs machine vibrations and external shocks better than metal, which helps to settle the measuring system faster and ensures more stable readings.

-

Hardness and Wear Resistance: Granite is extremely hard, typically registering between 6 and 7 on the Mohs scale. This provides a wear surface that is not only highly durable but, crucially, any wear that does occur tends to manifest as localized chipping rather than the smooth distortion (dishing) typical of metal, thus preserving the overall flatness longer.

-

Non-Magnetic and Non-Rusting: Granite is impervious to magnetic fields and does not rust, eliminating two major sources of potential error and contamination that can affect magnetic-based measurement setups and sensitive instruments.

Ensuring Longevity and Maintaining Grade

The grade of a surface plate is not a permanent state; it must be maintained. The precision relies on the initial lapping and polishing process, where highly skilled technicians meticulously bring the surface within the defined tolerance of the granite surface plate grade chart.

-

Calibration Cycle: Regular, certified calibration is non-negotiable. The frequency depends on the plate’s grade, usage intensity, and the environmental conditions. A high-use, Inspection Grade plate might require calibration every six to twelve months.

-

Cleanliness: Dust and particulate matter are the surface plate’s worst enemies. They act as abrasive particles, causing wear, and create subtle, localized high points that compromise flatness. Proper cleaning with specialized surface plate cleaner is essential before and after use.

-

Proper Use: Never drag heavy parts across the surface. Use the plate primarily as a reference plane, not a workbench. Distribute loads evenly, and ensure the plate is correctly mounted on its specified support system, which is designed to prevent sagging and maintain the integrity of its certified flatness.

The SEO Angle: Targeting the Right Expertise

For businesses serving the precision industry, mastering the terminology related to granite surface plate grade 1, granite surface table grades, and grade A granite surface plate is key to digital visibility. Search engines prioritize content that is authoritative, technically accurate, and directly answers user intent. A comprehensive article that delves into the ‘why’ behind the grades, the scientific basis of the material choice, and the practical implications for quality control not only attracts potential customers but establishes the provider as a thought leader in metrology.

The modern engineering and manufacturing environment demands absolute certainty. The granite surface plate remains the gold standard for dimensional metrology, and understanding its grading system is the first step toward achieving verifiable, world-class precision. Choosing the right plate—whether the standard-setting accuracy of a granite surface table grade 0 or the reliable precision of a Grade 1—is an investment that pays dividends in quality assurance and reduced rework, ensuring every component that leaves your facility meets the tightest specifications.

Post time: Nov-26-2025