For manufacturers and metrologists across North America, from the industrial heartlands of the United States to the demanding standards of granite surface plate Canada suppliers, the granite surface plate is the definitive anchor of dimensional measurement. This foundational tool, whether serving as a simple reference plane or integrated as a critical component in advanced machinery like a granite surface plate CNC bed, represents a significant investment in quality control. Yet, securing that investment requires a deep understanding of its cost drivers, maintenance needs, and the assurance of proper calibration.

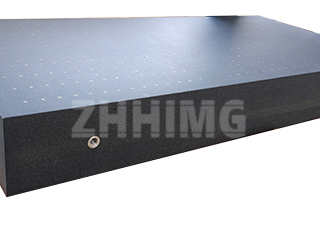

The initial query, “What is the granite surface plate cost?”, opens the door to a complex value proposition. The price of a surface plate is not merely the cost of raw material; it is a reflection of the stone’s quality (density, porosity, and stability), the precision of the lapping process, and the rigor of the certification process. Cheaper, lower-density granite, often identified by its lighter color, may save on the upfront granite surface plate cost, but it inevitably leads to higher long-term expenses due to faster wear, greater susceptibility to thermal instability, and more frequent re-calibration. Premium black granite, like the proprietary material utilized by ZHHIMG® with a density near 3100 kg/m³, ensures superior stability and less frequent maintenance, making it a more economical choice over the life cycle of the product.

This longevity is directly tied to the essential practices of granite surface plate care. A granite plate, despite its apparent rigidity, is vulnerable to two primary antagonists: abrasive wear and thermal shock. A comprehensive granite surface plate care regimen must address both proactively.

A critical component of this regimen is granite surface plate cleaning. The meticulous process of cleaning granite surface plate surfaces is not simply about removing visible dirt; it is about eliminating microscopic, abrasive particles—such as grinding dust or metallic swarf—that, when trapped between the workpiece and the granite, act like sandpaper, destroying the certified flatness. Never use harsh detergents or acidic cleaners, which can leave residues or etch the stone’s surface. Instead, a dedicated, pH-neutral granite surface plate cleaning solution, paired with a specialized, lint-free cloth, must be used daily to maintain the pristine condition of the reference plane. This routine step is non-negotiable for preserving accuracy, particularly for plates operating at Grade 00 or laboratory tolerances.

However, even the most rigorous cleaning and care cannot entirely prevent the slow, cumulative effects of use and environmental changes. This brings us to the necessity of a truly calibrated granite surface plate. The term “calibrated” is often misused; it must imply a traceable verification of the plate’s overall flatness, local area flatness, and repeatability. High-precision industries, including those served by granite surface plate Canada suppliers, rely on traceable calibration certificates issued by accredited laboratories that use laser interferometry and electronic levels.

ZHHIMG®’s commitment to precision ensures that every plate leaving their 10,000 m² climate-controlled facility—a structure built with vibration-damped concrete and seismic isolation trenches—has been meticulously verified. This dedication is especially important when the plate is used as the granite surface plate CNC base. In this application, the plate acts as the structural foundation for the machine’s linear guides and motors. Any geometric error in the granite is immediately translated into errors in the CNC’s motion control, directly impacting the final machined part accuracy. Consequently, the calibration interval for a granite surface plate CNC application should be more frequent and stringent than that for a standard inspection plate.

Beyond flatness and material quality, users must also consider the structural design. The proper engineering of the granite block surface plate—including the design and placement of lifting inserts, support points, and the overall thickness-to-span ratio—is vital to prevent deflection under load. This structural integrity is a major factor driving the true granite surface plate cost and is a hallmark of world-class manufacturers who understand that precision is built from the ground up.

By prioritizing superior material density, implementing a disciplined granite surface plate care and cleaning granite surface plate regimen, and committing to traceable, regular calibrated granite surface plate services, users ensure their metrology foundation remains an unwavering reference point, delivering consistent, nanometer-level accuracy regardless of where they source their plates—be it from a local vendor or an international leader like ZHHIMG®.

Post time: Nov-25-2025