In the relentless pursuit of zero-defect manufacturing, the integrity of the measurement foundation is non-negotiable. Every high-stakes dimensional inspection, from validating CMM components to setting up laser guides, relies absolutely on the stability of the granite block surface plate. This raises a crucial question for engineers and metrologists: What criteria truly define the best granite surface plate in today’s demanding industrial landscape?

The industry has long recognized legacy names and specific quality benchmarks. Discussions often revolve around established products, such as the renowned Brown & Sharpe granite surface plate offerings, which set early standards for accuracy and reliability. However, as measurement tolerances have tightened and moved into the sub-micron and nanometer regimes, the bar for the “best” has been significantly raised, requiring superior material science and manufacturing consistency.

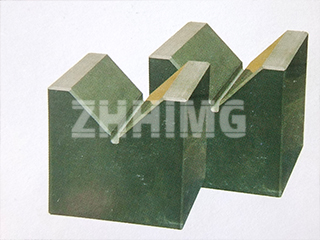

The choice between a standard granite surface plate and one designed for ultra-precision fundamentally comes down to the stone’s physical properties. Many manufacturers seek out high-density, black granite due to its excellent vibration dampening, low thermal expansion coefficient, and minimal water absorption—traits critical for maintaining flatness stability over time. While the quality of black granite, such as the material used in a Brown and Sharpe black granite surface plate, is well-regarded, ZHHIMG® utilizes a proprietary material, the ZHHIMG® Black Granite, which achieves an exceptional density approaching 3100 kg/m³. This superior density provides the inert stability necessary to serve as the ultimate granite block surface plate foundation for today’s fastest and most sensitive metrology equipment.

Achieving the coveted nanometer flatness—which distinguishes a great plate from the best granite surface plate—is not just about the stone; it is about the manufacturing ecosystem. It requires more than just skilled lapping. It necessitates a complete manufacturing environment that eliminates all external variables. ZHHIMG®’s massive facility near Qingdao port features a 10,000 m² constant temperature and humidity cleanroom. This space is constructed with over 1000mm of vibration-damped concrete, surrounded by seismic isolation trenches, ensuring that the very floor upon which the final lapping takes place is stable and free from external influence. This level of environmental control is critical because even minuscule thermal gradients or vibrations can compromise flatness at the highest grades.

Furthermore, a true leader in the field must demonstrate commitment not just to product quality, but to comprehensive process quality. ZHHIMG® holds the unique distinction of being the only manufacturer in the ultra-precision components sector to be simultaneously certified to ISO 9001 (Quality), ISO 45001 (Safety), ISO 14001 (Environment), and CE standards. This commitment to all facets of quality management—from ethical sourcing to environmental stewardship—offers customers a level of trust and accountability that complements the technical specifications of their granite block surface plate.

The commitment extends to people, too. The artisans who perform the final surface finishing possess decades of manual lapping experience, allowing them to achieve surface tolerances that clients often refer to as “nanometer precision.” When paired with state-of-the-art measurement tools—such as traceable laser interferometers and electronic levels—this combination of superior material, controlled environment, and unmatched human skill sets a new global benchmark.

Ultimately, choosing the best granite surface plate involves looking beyond historical brand names and focusing on certified material density, manufacturing consistency, and a verifiable commitment to the ultra-precision industry’s highest standards. For manufacturers demanding maximum stability and absolute accuracy for their most critical operations, the foundation provided by ZHHIMG® represents the next generation of metrology certainty.

Post time: Nov-25-2025