In the current era of ultra-precision manufacturing, we are no longer debating millimeters or even microns. We are operating in a world where the diameter of a human hair is considered a vast, canyon-like distance. From the intricate etching of silicon wafers to the alignment of satellite optical systems, the demand for “absolute zero” in terms of mechanical interference has never been higher. Yet, many high-tech facilities continue to overlook the most critical component of their assembly: the ground truth. This leads to a fundamental inquiry that every lead engineer and quality manager must eventually face: is the platform supporting your innovation as stable as the science behind it?

At ZHHIMG (ZhongHui Intelligent Manufacturing), we have spent nearly four decades answering this question by looking beneath the surface. We have found that the most sophisticated technology on the planet performs only as well as the reference it sits upon. This realization has cemented our role as a global leader in the production of high-performance granite components. Whether it is a localized granite surface block for a toolroom or a massive, multi-ton precision granite table for a semiconductor lithography line, the pursuit is always the same—the elimination of uncertainty.

The Geological Blueprint of Stability

To understand why a granite surface block has become the gold standard in metrology, one must look at the clock of the Earth. While humans can forge steel and cast iron in a matter of hours, nature takes millions of years to create granite. This igneous rock, formed under immense pressure and heat deep within the Earth’s crust, has reached a state of physical equilibrium that man-made materials simply cannot replicate.

When a metal component is manufactured, it retains internal stresses. Over time, these stresses “relax,” leading to microscopic warping and dimensional drift. Granite, however, has already finished its internal movements. When we extract a block from our carefully selected quarries in Shandong, we are working with a material that is geologically “quiet.” This inherent stability ensures that an inspection surface plate crafted by ZHHIMG remains flat to within a fraction of a micron for years, providing a consistent reference that is unaffected by the passage of time.

Furthermore, the mineral composition of granite—rich in quartz and feldspar—provides a natural resistance to the elements. Unlike cast iron, which is prone to oxidation and corrosion, a granite surface block is chemically inert. It does not rust when exposed to the humidity of a shop floor, nor does it require the messy oiling and constant maintenance that metallic plates demand. This “clean” performance is precisely why granite is the mandatory choice for the world’s most advanced cleanrooms.

Engineering the Precision Granite Table for the Nanometer Age

As industries like aerospace and semiconductor manufacturing move toward larger components and tighter tolerances, the physical scale of precision has expanded. A standard workbench is no longer sufficient for inspecting a five-meter-long aircraft wing rib or the massive gantries of a chip-printing machine. This shift has necessitated the development of the precision granite table—a feat of engineering that bridges the gap between raw geology and high-tech integration.

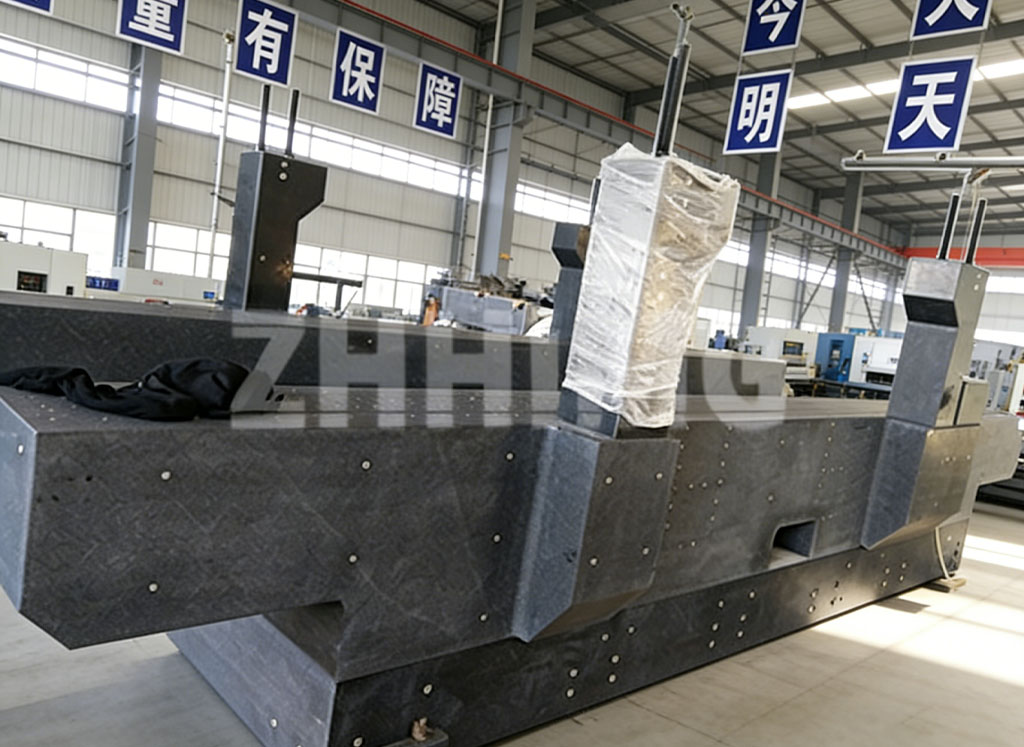

At ZHHIMG, we are one of the few organizations globally with the infrastructure to produce monolithic granite components of staggering scale. Our facilities are equipped to handle single-piece tables that can stretch up to 20 meters in length and weigh over 100 tons. However, the challenge is not just the size; it is maintaining uniform accuracy across that entire span.

A precision granite table from our facility undergoes a rigorous sequence of diamond-grinding and temperature-controlled seasoning. By utilizing advanced laser interferometry, we ensure that every square centimeter of the table adheres to the specified flatness, squareness, and parallelism. For the engineer, this means that the “floor” of their machine is no longer a variable. It is a constant. This level of reliability allows for faster calibration, higher throughput, and the kind of repeatable accuracy that defines the top tier of global manufacturing.

The Inspection Surface Plate: The Silent Referee of the Lab

In any quality control laboratory, the inspection surface plate is the silent referee. It is the plane against which every part is judged and every instrument is calibrated. If the referee is biased, the entire game is lost. This is why the craftsmanship involved in creating a surface plate is so vital.

While automation has taken over much of modern manufacturing, the final grade of a ZHHIMG inspection surface plate is still achieved through the expert hands of our master lappers. Hand-lapping is a meticulous process of removing material in increments so small they defy standard measurement. By using a series of abrasive pastes and specialized laps, our technicians can sense imperfections that sensors might overlook. This human touch, refined over decades of experience, is what allows us to achieve Grade 00 and even Grade 000 accuracy—levels of flatness that are essential for the most demanding optical and electronic measurements.

One of the most practical yet overlooked benefits of the inspection surface plate made of granite is its reaction to accidental impact. In a busy lab, tools are dropped and parts are moved. When a metal plate is struck, the material “mushrooms” upward, creating a burr that can ruin subsequent measurements. Granite, because of its brittle crystalline structure, simply chips. The surrounding area remains perfectly flat, allowing work to continue without the need for expensive re-grinding. It is this combination of extreme accuracy and industrial durability that makes our plates a permanent fixture in the world’s best-equipped facilities.

Navigating the Thermal Landscape

Perhaps the greatest enemy of precision is temperature. Heat causes materials to expand, and in a high-precision setup, even a one-degree Celsius fluctuation can cause a support structure to grow or warp. Metals are notoriously reactive to thermal changes, making them problematic for long-term inspection cycles.

Granite possesses a significantly lower coefficient of thermal expansion compared to most metals. More importantly, it has high thermal inertia. This means it does not react impulsively to a sudden draft or the warmth of a technician’s hand. A ZHHIMG precision granite table acts as a thermal buffer, maintaining a steady state even when the surrounding environment is less than perfect. This characteristic is why our bases are integrated into the most sensitive laser-guided inspection systems—systems where even a microscopic thermal drift would render the data useless.

Why ZHHIMG is Recognized Among the World’s Leading Manufacturers

The global market for precision stone is specialized, and ZHHIMG has earned its place among the top ten companies worldwide through a commitment to both scale and science. We operate two massive manufacturing bases that combine the raw power of heavy industry with the finesse of a metrology lab. This vertical integration—from the quarry to the final hand-lapping—allows us to maintain a level of quality control that is rare in the industry.

Our reputation in the European and American markets is built on the principle of being a “thought partner” rather than just a vendor. We understand that a granite surface block is often just one piece of a complex puzzle. Our engineering team works directly with clients to design custom solutions, including integrated threaded inserts, T-slots, and air-bearing surfaces, all machined into the granite with the same sub-micron precision as the surface itself.

We believe that the trust placed in our products by aerospace giants, medical device innovators, and research institutions is a reflection of our dedication to the “science of stillness.” In an age where everything is moving faster, ZHHIMG provides the world with a place to stand perfectly still.

The Future of Precision Foundations

As we look toward the next decade, the requirements for stability will only become more extreme. The rise of 2nm semiconductor nodes and the miniaturization of robotic surgical tools will demand foundations that are even more inert and even more precise. At ZHHIMG, we are already preparing for this future by experimenting with hybrid materials, combining the natural advantages of a granite surface block with the vibration-damping properties of advanced polymer composites.

The goal remains unchanged: to provide our clients with a reference surface that is so reliable, they never have to think about it. By choosing a ZHHIMG precision granite table or inspection surface plate, you are not just buying a piece of stone; you are investing in the absolute certainty of your measurements.

We invite the global engineering community to visit our digital home at www.zhhimg.com to explore our capabilities and see how our commitment to geological perfection can become the foundation of your next breakthrough. In the world of high precision, the foundation is everything. Make sure yours is written in stone.

Post time: Dec-23-2025