In the fast-paced world of electronics manufacturing, where the miniaturization of devices drives relentless innovation, Surface-mount technology (SMT) remains the critical process for placing components onto printed circuit boards (PCBs). Modern SMT equipment—pick-and-place machines, screen printers, and automated optical inspection (AOI) systems—must operate at speeds and levels of accuracy that border on the impossible. The stability and integrity of the machine’s foundation are not merely supporting factors; they are the ultimate constraint on throughput and yield. For many high-performance systems, the robust, unwavering solution lies in the adoption of a specialized granite machine base for Surface-mount technology.

As component sizes continue to shrink (down to 01005 and beyond), and placement speeds soar, the entire dynamic stability of the system must be re-evaluated. This is why leading equipment manufacturers are turning to the intrinsic properties of natural stone to create the definitive Surface-mount technology granite machine base.

The Imperative for a Granite Base in High-Speed SMT

Why is an ancient, natural material the optimal choice for cutting-edge SMT automation? The answer is rooted in the fundamental physics of precision motion. High-speed SMT machines generate significant dynamic forces. Rapid acceleration and deceleration of gantry systems, heads, and conveyors create vibrations that, if not managed, can propagate throughout the machine structure. This oscillation directly translates into placement inaccuracies, soldering defects, and decreased inspection fidelity.

The solution is the granite machine bed for Surface-mount technology. Granite’s properties make it the superior material for absorbing and dampening these internal and external disturbances:

-

Superior Damping Characteristics: Compared to steel or aluminum, granite has a significantly higher internal damping coefficient. This means mechanical vibrations caused by high-speed motion are quickly dissipated as minute amounts of heat, preventing them from destabilizing the placement head or inspection optics. This instantaneous settling time is crucial for maximizing throughput without sacrificing accuracy.

-

Thermal Inertia and Low CTE: The SMT environment, particularly near reflow ovens or within the immediate operational area, can experience minor temperature swings. Metals react strongly to these changes, leading to thermal expansion and dimensional drift. However, the low coefficient of thermal expansion (CTE) of a granite bed for Surface-mount technology ensures the machine’s critical alignment geometry remains stable over the operational temperature range. This thermal stability is essential for maintaining alignment integrity, especially over large machine footprints.

-

Ultimate Flatness for Precision Motion: Granite can be lapped and polished to achieve flatness tolerances measured in sub-microns. This extreme level of precision is non-negotiable for mounting precision linear guides, air bearings, and motor systems. The high dimensional accuracy of the granite base for Surface-mount technology ensures perfect straightness and alignment for the fast-moving axes, which is the direct determinant of component placement accuracy.

Engineering the Next Generation of SMT: Components and Integration

The role of granite in SMT extends beyond the large granite machine base. A robust SMT platform often utilizes custom-engineered granite components for Surface-mount technology that are integrated into the main structure. These components may include:

-

Precision Mounting Blocks: Used to ensure the absolute stable positioning of highly sensitive vision systems, laser alignment sensors, and fiducial cameras.

-

Air Bearing Surfaces: For ultra-high-precision pick-and-place heads, granite provides an ideal, highly polished, non-porous surface that works perfectly with air bearings, offering near-frictionless, repeatable motion.

-

Custom Tooling Plates: Smaller granite elements designed to hold and reference specific process tooling, guaranteeing repeatable alignment over time and temperature.

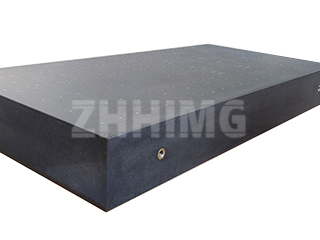

The manufacturing process for a high-performance granite machine base for Surface-mount technology is a testament to the blend of traditional craftsmanship and advanced engineering. It involves selecting the highest-quality natural black granite, stress-relieving it, and then machining it using state-of-the-art CNC equipment. Features such as tapped holes, T-slots, cored holes for cable routing, and bonding surfaces for metallic inserts are meticulously integrated to the customer’s exact specifications.

The Return on Investment: Precision and Longevity

Investing in a granite foundation for SMT equipment is a strategic decision that offers a clear return on investment. While the initial material cost may be higher than steel, the long-term benefits in terms of maximized production yield, reduced scrap, and minimal downtime due to structural misalignment far outweigh the difference.

A granite bed for Surface-mount technology provides a reliable, enduring reference plane that will maintain its dimensional integrity for decades, resisting wear, corrosion, and internal structural changes. For manufacturers operating at the cutting edge of electronics assembly, where precision means the difference between a successful product and a failed production run, the stability provided by a specialized granite machine base for Surface-mount technology is the ultimate guarantee of performance and reliability. Choosing a machine with this foundation is choosing consistency, speed, and uncompromising quality in the assembly of the world’s most intricate electronic devices.

Post time: Dec-01-2025