In the field of picosecond-level laser marking machines, precision is the core indicator for evaluating the performance of the equipment. The base, as a key carrier for the laser system and precision components, its material directly affects the stability of processing accuracy. Granite and cast iron, as two mainstream base materials, have significant differences in the precision attenuation characteristics during picosecond-level ultra-fine processing. This article will deeply analyze the performance advantages and disadvantages of the two to provide a scientific basis for equipment upgrading.

Material properties determine the basis of precision

Granite is essentially an igneous rock formed through geological processes over hundreds of millions of years. Its internal crystal structure is dense and uniform, with a linear expansion coefficient as low as 0.5-8 ×10⁻⁶/℃, comparable to that of precision alloys such as indium steel. This characteristic makes its dimensional change almost negligible when the ambient temperature fluctuates, effectively avoiding optical path offset and mechanical errors caused by thermal expansion and contraction. In addition, the density of granite is as high as 2.6-2.8g /cm³, which naturally possesses excellent vibration absorption capacity. It can rapidly attenuate the high-frequency vibrations generated during laser processing, ensuring the stability of the optical system and moving parts.

Cast iron bases are widely used due to their excellent casting performance and cost advantages. The typical flake graphite structure of gray cast iron endows it with certain damping performance, which can absorb about 30% to 50% of the vibration energy. However, the coefficient of thermal expansion of cast iron is approximately 10-12 ×10⁻⁶/℃, which is 2-3 times that of granite. Under the accumulation of heat generated by long-term continuous processing, dimensional deformation is prone to occur. Meanwhile, there is casting stress inside the cast iron. As the stress is released during the usage process, it may cause irreversible changes in the flatness and perpendicularity of the base.

The precision attenuation mechanism in picosecond-level processing

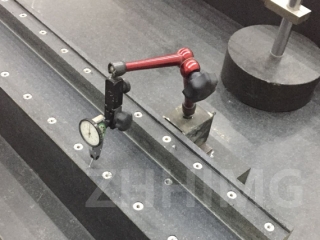

Picosecond laser processing, with its ultra-short pulse characteristics, can achieve fine processing at the sub-micron level or even the nanometer level, but it also poses strict requirements for the stability of the equipment. The granite base, with its stable internal structure, can control the vibration response at the sub-micron level under high-frequency laser impact, effectively maintaining the positioning accuracy of the laser focus. The measured data shows that the laser marking machine with a granite base still maintains a line width deviation within ±0.5μm after continuous 8-hour picosecond processing.

When the cast iron base is exposed to the high-frequency vibration of picosecond laser, the internal grain structure will undergo microscopic fatigue due to continuous impact, resulting in a decrease in the rigidity of the base. Monitoring data from a certain semiconductor manufacturing enterprise shows that after six months of operation, the processing accuracy attenuation rate of equipment with cast iron bases reaches 12%, mainly manifested as an increase in the roughness of line edges and an expansion of positioning errors. Meanwhile, cast iron is relatively sensitive to environmental humidity. Long-term use is prone to rust, further accelerating the deterioration of precision.

Verification of performance differences in practical applications

In the field of 3C electronic precision component processing, a well-known enterprise conducted a comparative test on the equipment performance of two types of material bases. In the experiment, two picosecond laser marking machines with the same configuration were respectively equipped with granite and cast iron bases to cut and mark the glass of mobile phone screens with a width of 0.1mm. After 200 hours of continuous processing, the retention rate of processing accuracy of the granite base equipment was 98.7%, while that of the cast iron base equipment was only 86.3%. The edges of the glass processed by the latter showed obvious sawtooth defects.

In the manufacturing of aerospace components, the long-term monitoring data of a certain research institute more intuitively reflects the differences: The laser marking machine with a granite base has a cumulative precision attenuation of less than 3μm within a five-year service life; However, after three years, the processing error of the cast iron base equipment caused by the deformation of the base has exceeded the process standard of ±10μm, and the overall machine accuracy calibration has to be carried out.

Suggestions for upgrading decisions

If enterprises take high-precision and long-cycle stable processing as their core demands, especially in fields such as semiconductor chips and precision optical components, granite bases, with their outstanding thermal stability and vibration resistance, are an ideal upgrade choice. Although its initial procurement cost is 30% to 50% higher than that of cast iron, from the perspective of the full life cycle cost, the reduced frequency of precision calibration and equipment downtime for maintenance can significantly enhance the overall benefits. For application scenarios with relatively low processing accuracy requirements and limited budgets, cast iron bases can still be used as a transitional solution under the premise of reasonably controlling the usage environment.

By systematically comparing the precision attenuation characteristics of granite and cast iron in picosecond-level processing, it can be seen that choosing the appropriate base material is a key step to improve the processing accuracy and reliability of the laser marking machine. Enterprises should, in light of their own technological requirements and cost considerations, make scientific decisions on the base upgrade plan to provide a solid equipment foundation for high-end manufacturing.

Post time: May-22-2025