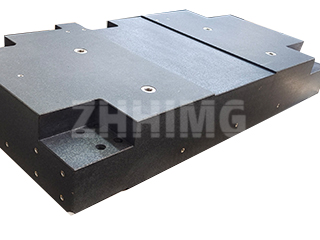

Granite components serve as the foundational benchmark for precision industries, and their performance and maintenance directly impact the reliability of measurement results. At ZHHIMG®, we understand the critical importance of material selection and daily care. We’ve compiled a professional guide for leveling and maintaining your granite components to ensure your equipment remains in optimal condition.

We exclusively select and use our premium ZHHIMG® Black Granite. With its dense crystalline structure and exceptional hardness, it boasts a compressive strength of up to 2290-3750 kg/cm² and a Mohs hardness of 6-7. This superior material is resistant to wear, acid, and alkali, and it will not rust. Even if the work surface is accidentally impacted or scratched, it will only result in a slight indentation, not a raised burr that would affect measurement accuracy.

Pre-Application Preparation for Granite Components

Before beginning any measurement task, thorough preparation is crucial for guaranteeing precision:

- Inspect and Clean: Confirm that the granite component’s surface is clean and free from rust, damage, or scratches. Use a clean, soft cloth or lint-free fabric to thoroughly wipe the working surface, removing all oil stains and debris.

- Workpiece Ready: Before placing a workpiece on the component, ensure its measuring surface is clean and burr-free.

- Organize Tools: Arrange all instruments and tools neatly; avoid stacking them.

- Protect the Surface: For delicate components, a soft velvet cloth or a soft wiping cloth can be placed on the workbench for protection.

- Record and Verify: Check calibration records before use and, if necessary, perform a quick verification.

Routine Maintenance and Cleaning

Correct and consistent daily maintenance is essential for extending the life of your granite components.

- Post-Use Cleaning: After each use, the working surface should be cleaned immediately.

- Apply Protective Oil: After cleaning, apply a thin layer of protective oil (such as machine oil or diesel) to the surface. The main purpose of this protective layer is not to prevent rust (as granite doesn’t rust), but to prevent dust from adhering, ensuring a clean surface for the next use.

- Authorized Personnel: Any disassembly, adjustment, or modification of the component should only be carried out by trained professionals. Unauthorized actions are strictly prohibited.

- Regular Inspection: Periodically check the component’s performance and maintain a detailed maintenance log.

Granite Component Leveling Methods

Leveling a granite component is a critical step in establishing a precise reference plane. Here are two effective leveling methods:

- Precision Instrument Method:

- Begin by using a frame level, electronic level, or autocollimator for initial leveling.

- Next, use a bridge level in conjunction with a level to inspect the surface section by section. Calculate the flatness based on the measurements and then make micro-adjustments to the component’s support points.

- Practical Adjustment Method:

- Before adjusting, ensure all support points are firmly in contact with the ground and are not suspended.

- Place a straight edge on the diagonal of the component. Gently rock one end of the ruler. The optimal support point should be located at approximately the 2/9 mark along the ruler’s length.

- Follow the same process to adjust all four corners of the component. If the component has more than three support points, use the same method to adjust the auxiliary points, noting that the pressure on these points should be slightly less than on the main four corners.

- After this method, a final check with a frame level or autocollimator will show that the entire surface is extremely close to perfectly level.

The Superior Performance of Granite Components

Granite components are superior to traditional cast iron platforms due to their unparalleled physical properties:

- Exceptional Stability: Formed over millions of years of natural aging, granite’s internal stress is completely eliminated, and its structure is uniform. This ensures the component will not deform.

- High Hardness: Its excellent rigidity and hardness, along with strong wear resistance, make it an ideal base for high-precision measurement.

- Non-Magnetic: As a non-metallic material, it allows for smooth, uninterrupted movement during measurement and is unaffected by magnetic forces.

ZHHIMG®, a benchmark in the industry, ensures that every granite component meets the highest standards of precision. All of our products are thoroughly protected before leaving the factory and after maintenance, guaranteeing their superior performance in a clean, low-vibration, and temperature-stable environment.

Post time: Sep-30-2025