In high-end manufacturing and precision engineering, the performance of a machine is determined not only by its drives, controls, or software, but fundamentally by its structural foundation. Machine tool bases and reference assemblies directly influence accuracy, vibration behavior, thermal stability, and long-term reliability. As manufacturing tolerances continue to tighten across industries such as aerospace, semiconductor equipment, optics, and advanced automation, material selection for machine bases has become a strategic engineering decision.

Among the most commonly evaluated solutions are epoxy granite machine bases, traditional cast iron machine tool bases, and natural precision granite assemblies. In parallel, granite surface plates remain essential reference components within both production and metrology environments. This article provides a structured analysis of these materials and components, examines their respective advantages and limitations, and outlines how precision granite assemblies support modern manufacturing systems. It also highlights how ZHHIMG delivers engineered granite solutions aligned with the requirements of global industrial customers.

Epoxy Granite Machine Base: Characteristics and Use Cases

Epoxy granite, also referred to as polymer concrete or mineral casting, is a composite material formed by binding mineral aggregates with epoxy resin. It has gained attention as an alternative machine base material due to its vibration damping characteristics and flexible molding capabilities.

One of the primary advantages of an epoxy granite machine base is its high internal damping. Compared to metal structures, epoxy granite can significantly reduce vibration transmission, improving surface finish and dynamic stability in certain machining applications. Additionally, complex geometries, internal channels, and embedded components can be integrated during the casting process, reducing secondary machining requirements.

However, epoxy granite also presents limitations. Long-term dimensional stability depends heavily on resin formulation, curing quality, and environmental conditions. Resin aging, temperature sensitivity, and potential creep effects must be carefully considered in ultra-precision or long-life applications. As a result, epoxy granite is often selected for medium-precision machine tools rather than systems requiring extreme accuracy over decades of service.

Cast Iron Machine Tool Base: Tradition and Constraints

Cast iron has been the traditional material of choice for machine tool bases for over a century. Its popularity stems from good machinability, reasonable damping, and established manufacturing processes. Many conventional CNC machines and general-purpose equipment continue to rely on cast iron structures.

Despite these advantages, cast iron machine tool bases exhibit inherent drawbacks in high-precision environments. Residual stresses introduced during casting and machining can lead to gradual deformation over time, even after stress-relief treatments. Cast iron is also more sensitive to thermal expansion and environmental temperature fluctuations, which can directly impact positioning accuracy.

Corrosion resistance is another consideration. Cast iron bases typically require protective coatings and controlled environments to prevent oxidation, particularly in humid or cleanroom-adjacent settings. These factors have prompted equipment manufacturers to evaluate alternative materials for applications demanding higher stability and lower maintenance.

Precision Granite Assembly: A Structural Advantage

Precision granite assemblies represent a fundamentally different approach to machine structure design. Formed from natural granite that has undergone geological aging over millions of years, granite is inherently stress-free and isotropic. This natural stability provides a significant advantage in maintaining long-term geometric accuracy.

Precision granite assemblies are manufactured through controlled grinding and lapping processes, achieving micron-level flatness, straightness, and perpendicularity. Unlike cast or composite materials, granite does not suffer from internal stress relaxation, making it highly suitable for ultra-precision and long-life applications.

In addition to dimensional stability, granite offers excellent vibration damping and a low coefficient of thermal expansion. These properties contribute to improved dynamic performance, reduced thermal drift, and consistent accuracy across extended operating periods. Granite is also non-magnetic and corrosion-resistant, enabling use in cleanrooms, optical systems, and precision inspection environments.

Granite Surface Plate: Foundation of Precision Reference

The granite surface plate is one of the most widely recognized and essential precision granite components. Serving as a flat reference plane, it underpins dimensional inspection, calibration, and assembly processes across manufacturing industries.

Granite surface plates are used extensively in quality control laboratories, production inspection areas, and metrology rooms. Their wear resistance and stability allow them to maintain accuracy over long service life with minimal maintenance. Compared to cast iron surface plates, granite plates offer superior corrosion resistance, lower thermal sensitivity, and reduced recalibration frequency.

In advanced manufacturing environments, granite surface plates are increasingly integrated into machine assemblies, optical platforms, and automated inspection stations, extending their role beyond traditional standalone metrology tools.

Comparative Perspective: Material Selection for Machine Bases

When comparing epoxy granite machine bases, cast iron machine tool bases, and precision granite assemblies, material selection should be driven by application requirements rather than initial cost alone.

Epoxy granite offers design flexibility and strong damping, making it suitable for vibration-sensitive but moderate-precision machines. Cast iron remains viable for conventional machine tools where cost efficiency and established manufacturing processes are priorities. Precision granite assemblies, however, provide unmatched long-term stability, thermal performance, and accuracy retention, making them the preferred solution for ultra-precision equipment and advanced metrology systems.

Lifecycle performance is an increasingly important evaluation criterion. While initial investment in precision granite assemblies may be higher, reduced maintenance, longer calibration intervals, and sustained accuracy often result in lower total cost of ownership.

Industry Trends and Evolving Design Strategies

Several industry trends are accelerating the adoption of granite-based machine structures. The growth of semiconductor manufacturing, optics, and laser processing has driven demand for ultra-stable platforms capable of sub-micron accuracy. Automation and digital manufacturing further emphasize the need for reliable structural foundations that can operate continuously with minimal drift.

Machine tool designers are increasingly adopting hybrid architectures that combine granite bases with linear motors, air bearings, and advanced control systems. In these configurations, granite assemblies provide the stability required to fully realize the performance potential of high-end motion and measurement technologies.

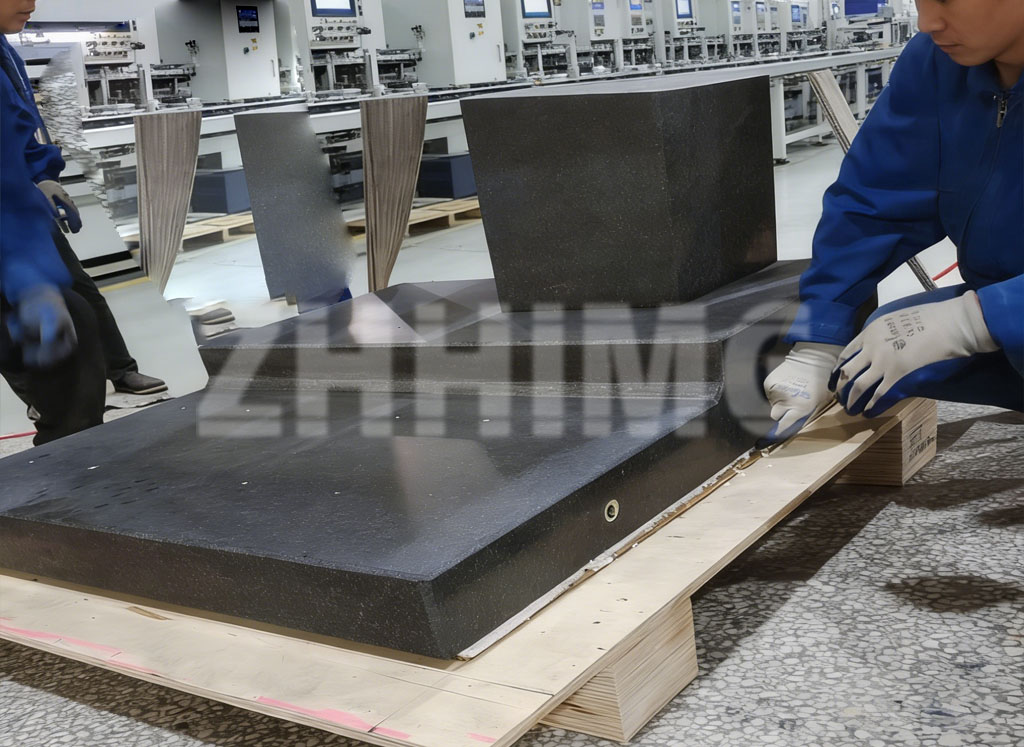

ZHHIMG’s Capabilities in Precision Granite Manufacturing

ZHHIMG specializes in the design and manufacturing of precision granite assemblies for global industrial customers. Utilizing premium black granite and advanced precision grinding technologies, ZHHIMG produces granite machine bases, surface plates, and custom assemblies that meet stringent international accuracy standards.

The company’s manufacturing processes are conducted under controlled environmental conditions, with comprehensive inspection at each stage to ensure consistency and reliability. ZHHIMG supports customers across machine tool manufacturing, metrology systems, semiconductor equipment, and advanced automation.

By collaborating closely with equipment designers and engineers, ZHHIMG delivers granite solutions that integrate seamlessly into complex machine architectures and support long-term performance objectives.

Conclusion

As manufacturing continues to move toward higher precision and greater system integration, the importance of machine base materials and reference assemblies will only increase. Epoxy granite machine bases and cast iron machine tool bases each retain relevance within specific application ranges, but precision granite assemblies offer distinct advantages in stability, accuracy, and lifecycle performance.

Granite surface plates and granite-based machine structures remain foundational elements in modern precision engineering. Through dedicated expertise in precision granite manufacturing, ZHHIMG is well positioned to support global customers seeking reliable, long-term solutions for advanced manufacturing and metrology applications.

Post time: Jan-21-2026