As global manufacturing moves decisively toward higher accuracy, higher speed, and greater stability, precision component manufacturing companies are under increasing pressure to deliver not only tighter tolerances, but also long-term reliability. In this context, precision granite components have become a foundational element in ultra-precision motion stages, advanced metrology systems, and high-end industrial equipment. Their unique material properties enable performance levels that are difficult to achieve with conventional metal structures.

This article explores the manufacturing of precision granite components, their critical role in ultra-precision motion stage systems, and the broader industry trends shaping demand among precision component manufacturing companies in Europe and North America. It also outlines how ZHHIMG supports global customers with engineered granite solutions designed for demanding industrial environments.

Precision Granite Components: Material Advantages and Engineering Value

Precision granite components are widely used in applications where dimensional stability, vibration damping, and thermal consistency are essential. Compared with steel, cast iron, or aluminum structures, granite offers a combination of physical properties that align closely with the requirements of ultra-precision systems.

Granite exhibits a low coefficient of thermal expansion, allowing components to maintain geometric accuracy even under fluctuating ambient temperatures. This characteristic is particularly important in ultra-precision motion stages, where micron- and sub-micron-level positioning accuracy must be preserved throughout long operating cycles.

In addition, the internal crystalline structure of high-density black granite provides excellent vibration damping. This reduces the transmission of external disturbances and improves dynamic performance in motion platforms, optical systems, and semiconductor equipment. Granite is also naturally corrosion-resistant and non-magnetic, making it suitable for cleanroom environments and sensitive measurement applications.

Manufacturing Precision Granite Components: From Raw Stone to Finished Structure

The manufacturing of precision granite components is a highly specialized process that combines material selection, controlled machining, and high-accuracy inspection. Unlike standard stone processing, precision granite manufacturing focuses on achieving flatness, straightness, and geometric tolerances measured in microns.

The process begins with careful selection of raw granite blocks. Only granite with uniform grain structure, high density, and minimal internal defects is suitable for precision applications. Once selected, the material undergoes stress-relief and aging processes to ensure long-term dimensional stability.

Machining and grinding are performed in temperature-controlled environments using precision equipment. Surface grinding, lapping, and fine finishing are applied to achieve the required flatness and surface quality. For complex components, precision drilling, slotting, and embedded inserts are integrated without compromising structural integrity.

Throughout manufacturing, dimensional verification is conducted using calibrated reference instruments, laser measurement systems, and coordinate measuring machines. This ensures that each precision granite component meets the specified accuracy requirements before delivery.

Ultra-Precision Motion Stages: Structural Requirements and Performance Drivers

Ultra-precision motion stages are central to applications such as semiconductor lithography, optical alignment, laser processing, and advanced inspection systems. These stages require exceptional stiffness, thermal stability, and damping to achieve repeatable, high-speed, high-accuracy motion.

Granite-based structures provide an ideal foundation for such systems. Precision granite bases and bridges support linear motors, air bearings, and guide systems while maintaining alignment under dynamic loads. The inherent damping characteristics of granite improve settling time and reduce positioning errors caused by vibration.

In many designs, granite components are combined with air bearing technology to achieve near-frictionless motion. This combination enables smooth, repeatable positioning with minimal wear, supporting long service life and reduced maintenance requirements.

Integration of Precision Granite in Motion Stage Systems

Successful integration of precision granite components into ultra-precision motion stages requires close collaboration between system designers and component manufacturers. Factors such as mounting interface design, load distribution, and thermal management must be considered early in the development process.

Custom granite structures are often engineered to accommodate linear motors, encoder systems, cable management, and vacuum or cleanroom requirements. Precision component manufacturing companies increasingly rely on custom granite solutions rather than standard catalog parts to optimize system performance.

ZHHIMG works closely with equipment manufacturers to develop granite bases, gantries, and frames that align with specific motion stage architectures. This collaborative approach ensures compatibility, accuracy, and long-term stability in demanding applications.

Industry Trends Driving Demand for Precision Granite Components

Several macro-level trends are driving increased demand for precision granite components across Europe and North America. The continued growth of semiconductor manufacturing has significantly increased requirements for ultra-stable machine platforms and inspection systems. At the same time, advances in optics, photonics, and laser-based manufacturing have raised expectations for positioning accuracy and environmental stability.

Automation and digital manufacturing also contribute to this trend. As production lines become more automated, inline measurement and high-speed motion systems must operate continuously with minimal drift. Granite-based structures help ensure consistent performance over extended operating periods.

These factors have positioned precision granite components as strategic elements within the supply chains of leading precision component manufacturing companies.

ZHHIMG’s Capabilities in Precision Granite Manufacturing

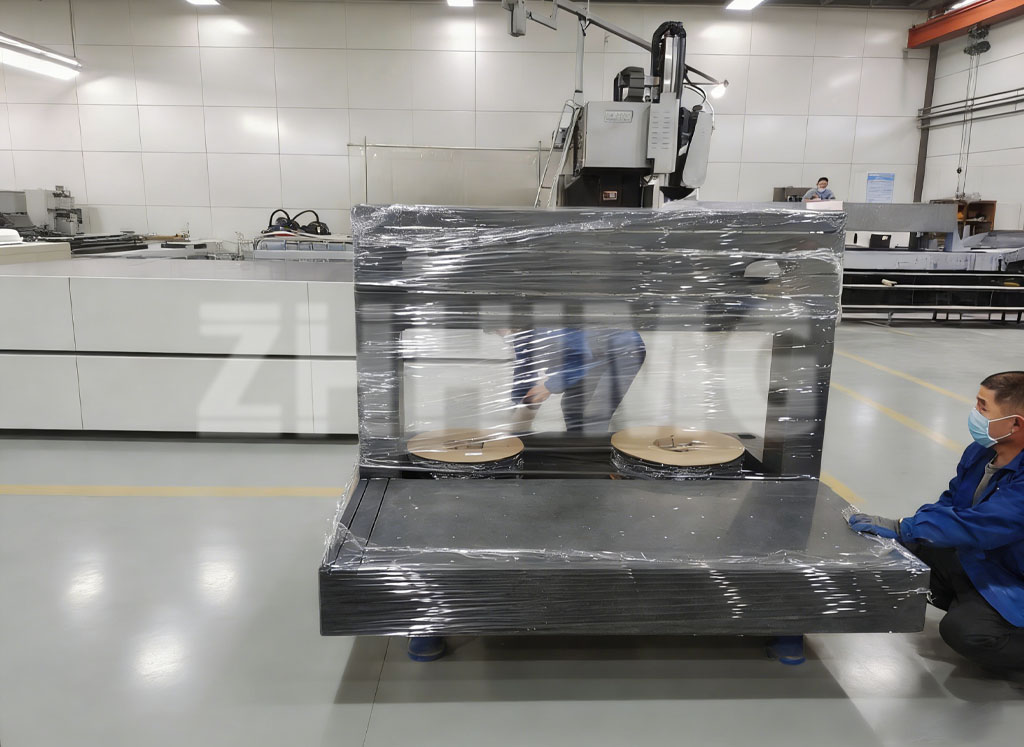

ZHHIMG specializes in the manufacturing of precision granite components for global industrial customers. By combining premium black granite materials with advanced precision grinding and inspection technologies, ZHHIMG delivers components that meet stringent international accuracy standards.

The company’s product portfolio includes granite bases for ultra-precision motion stages, precision surface plates, machine frames, and custom-engineered granite structures. Each component is manufactured under controlled environmental conditions and verified through comprehensive inspection procedures.

With experience supporting customers in semiconductor equipment, metrology systems, and high-end automation, ZHHIMG provides not only components, but also technical support throughout the design and integration process.

Conclusion

As ultra-precision manufacturing continues to advance, the role of precision granite components in motion systems and metrology equipment will only grow in importance. Their unique combination of thermal stability, vibration damping, and durability makes them a preferred choice for ultra-precision motion stages and high-end industrial applications.

For precision component manufacturing companies seeking reliable, long-term solutions, granite-based structures offer clear performance and lifecycle advantages. Through dedicated expertise in precision granite manufacturing, ZHHIMG remains committed to supporting global customers with engineered solutions that meet the evolving demands of modern industry.

Post time: Jan-21-2026