In the field of semiconductor manufacturing, precision is the lifeline of product quality and performance. Semiconductor metering equipment, as a key link to ensure production accuracy, imposes almost strict requirements on the stability of its core components. Among them, the granite platform, with its outstanding thermal stability, plays an indispensable role in semiconductor metering equipment. This article will conduct an in-depth analysis of the thermal stability performance of granite platforms in semiconductor metering equipment through actual test data.

The strict requirements for the thermal stability of measuring equipment in semiconductor manufacturing

The semiconductor manufacturing process is extremely complex and precise, and the width of the circuit lines on the chip has entered the nanometer level. In such a high-precision manufacturing process, even the slightest temperature change can cause thermal expansion and contraction of equipment components, thereby triggering measurement errors. For instance, in the photolithography process, if the measurement accuracy of the metering equipment deviates by 1 nanometer, it may cause serious problems such as short circuits or open circuits in the circuits on the chip, leading to the scrapping of the chip. According to industry data statistics, for every 1℃ fluctuation in temperature, the traditional metal material metering equipment platform may undergo dimensional changes of several nanometers. However, semiconductor manufacturing requires measurement accuracy to be controlled within ±0.1 nanometers, which makes thermal stability a key factor in determining whether the metering equipment can meet the demands of semiconductor manufacturing.

Theoretical advantages of the thermal stability of granite platforms

Granite, as a kind of natural stone, has a compact internal mineral crystallization, a dense and uniform structure, and possesses the natural advantage of thermal stability. In terms of the coefficient of thermal expansion, the coefficient of thermal expansion of granite is extremely low, generally ranging from 4.5 to 6.5×10⁻⁶/K. In contrast, the coefficient of thermal expansion of common metallic materials such as aluminium alloys is as high as 23.8×10⁻⁶/K, which is several times that of granite. This means that under the same temperature variation conditions, the dimensional change of the granite platform is much smaller than that of the metal platform, which can provide a more stable measurement reference for semiconductor metering equipment.

In addition, the crystal structure of granite endows it with excellent uniformity of heat conduction. When the equipment operation generates heat or the ambient temperature changes, the granite platform can quickly and evenly conduct away the heat, avoiding local overheating or overcooling phenomena, thereby effectively maintaining the overall temperature consistency of the platform and further ensuring the stability of measurement accuracy.

The process and method of thermal stability measurement

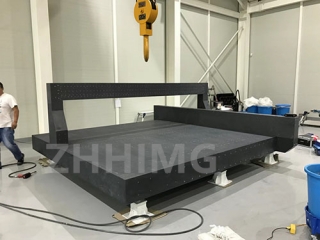

In order to accurately evaluate the thermal stability of the granite platform in semiconductor metering equipment, we have designed a rigorous measurement scheme. Select a high-precision semiconductor wafer measuring instrument, which is equipped with a super-precision processed granite platform. In the experimental environment, the common temperature variation range in the semiconductor manufacturing workshop was simulated, that is, gradually heating from 20℃ to 35℃ and then cooling back to 20℃. The entire process lasted for 8 hours.

On the granite platform of the measuring instrument, high-precision standard silicon wafers are placed, and displacement sensors with nanoscale accuracy are used to monitor the relative position changes between the silicon wafers and the platform in real time. Meanwhile, multiple high-precision temperature sensors are arranged at different positions on the platform to monitor the temperature distribution on the platform surface. During the experiment, the displacement data and temperature data were recorded every 15 minutes to ensure the completeness and accuracy of the data.

Measured data and result analysis

The relationship between temperature changes and platform size changes

Experimental data show that when the temperature rises from 20℃ to 35℃, the change in the linear size of the granite platform is extremely small. After calculation, throughout the entire heating process, the maximum linear expansion of the platform is only 0.3 nanometers, which is far lower than the error tolerance range for measurement accuracy in semiconductor manufacturing processes. During the cooling stage, the platform size can almost completely return to the initial state, and the lag phenomenon of size change can be ignored. This characteristic of maintaining extremely low dimensional changes even under significant temperature fluctuations fully validates the outstanding thermal stability of the granite platform.

Analysis of temperature uniformity on the platform surface

The data collected by the temperature sensor shows that during the operation of the equipment and the process of temperature change, the temperature distribution on the surface of the granite platform is extremely uniform. Even during the stage when the temperature changes most intensely, the temperature difference between each measurement point on the platform surface is always controlled within ±0.1℃. Uniform temperature distribution effectively avoids platform deformation caused by uneven thermal stress, ensuring the flatness and stability of the measurement reference surface, and providing a reliable measurement environment for semiconductor metrology equipment.

Compared with traditional material platforms

The measured data of the granite platform were compared with those of the semiconductor metering equipment of the same type using the aluminum alloy platform, and the differences were significant. Under the same temperature change conditions, the linear expansion of the aluminum alloy platform is as high as 2.5 nanometers, which is more than eight times that of the granite platform. Meanwhile, the temperature distribution on the surface of the aluminum alloy platform is uneven, with the maximum temperature difference reaching 0.8℃, resulting in obvious deformation of the platform and seriously affecting the measurement accuracy.

In the precise world of semiconductor metrology equipment, granite platforms, with their outstanding thermal stability, have become the mainstay in ensuring measurement accuracy. The measured data strongly prove the outstanding performance of the granite platform in responding to temperature changes, providing reliable technical support for the semiconductor manufacturing industry. As semiconductor manufacturing processes advance towards higher precision, the thermal stability advantage of granite platforms will become increasingly prominent, continuously driving technological innovation and development in the industry.

Post time: May-13-2025