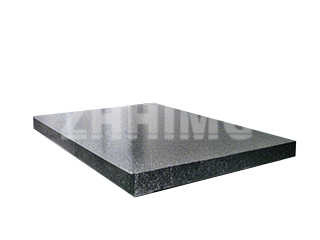

In the realm of ultra-precision metrology, the integrity of the Granite Component Platform is non-negotiable. While ZHHIMG® adheres to the highest manufacturing and inspection standards—certified by ISO 9001, 45001, and 14001—no natural material or process is entirely immune to potential issues. Our commitment is not just to produce quality, but to share the expertise required to understand and maintain that quality.

This guide outlines common issues that can affect Precision Granite Platforms and the professional methods used to mitigate or correct them, driving continuous performance improvement.

1. Loss of Flatness or Geometric Accuracy

The primary function of a granite platform is to provide a perfectly true reference plane. Loss of flatness is the most critical defect, often caused by external factors rather than material failure.

Cause and Impact:

The two main causes are improper support (the platform is not resting on its defined three primary support points, leading to deflection) or physical damage (heavy impact or dragging heavy objects across the surface, causing localized chipping or wear).

Improvement and Mitigation Methods:

- Re-Leveling and Support: Immediately check the platform’s installation. The base must strictly follow the three-point support principle to ensure the granite mass is freely resting and not subjected to twisting forces. Referencing our leveling guides is essential.

- Surface Re-Lapping: If the deviation exceeds the tolerance (e.g., Grade 00), the platform must be professionally re-lapped (re-ground). This process requires highly specialized equipment and the expertise of craftsmen with decades of experience, like those at ZHHIMG®, who can restore the surface to its original geometric accuracy.

- Protect from Impact: Implement strict operational protocols to prevent heavy tools or equipment from being dropped or dragged, protecting the surface from localized wear.

2. Cosmetic Defects: Staining and Discoloration

While not directly affecting the underlying mechanical precision, cosmetic defects can detract from the cleanliness required in environments like cleanrooms or high-end labs.

Cause and Impact:

Granite is naturally porous. Staining occurs when chemicals, oils, or pigmented liquids are allowed to sit on the surface, penetrating the pores. While ZHHIMG® Black Granite is highly resistant to acid and alkali corrosion, neglect will lead to visible mottling.

Improvement and Mitigation Methods:

- Immediate Cleaning: Spills of oil, grease, or corrosive chemicals must be cleaned immediately using only soft, lint-free cloths and neutral, approved granite cleaners. Avoid abrasive cleaning agents.

- Sealing (Periodic Maintenance): While often sealed during manufacturing, periodic professional application of a penetrating granite sealer can fill the microscopic pores, dramatically increasing resistance to future staining and making routine cleanup easier.

3. Edge Chipping or Cracking

Damage to the edges and corners is a common issue during transport, installation, or heavy use. While minor edge chipping doesn’t compromise the central working area, major cracks can render the platform unusable.

Cause and Impact:

High-impact stress, often concentrated on an unsupported edge during transit or moving, can cause chipping or, in severe cases, cracking due to the tensile force.

Improvement and Mitigation Methods:

- Safe Handling: Always use proper lifting equipment and secure rigging points. Never lift large platforms using unsupported edges.

- Epoxy Repair: Minor chips on the non-critical edges or corners can often be professionally repaired using a pigmented epoxy filler. This restores the cosmetic appearance and prevents further fragmentation, although it does not affect the certified measuring area.

- Scrapping Severe Damage: If a crack propagates significantly into the measuring surface, the structural integrity and stability are compromised, and the platform must typically be removed from service.

At ZHHIMG®, our goal is to supply components that minimize these issues from the start, thanks to our high-density materials (≈ 3100 kg/m³) and meticulous finishing. By understanding these potential defects and following best practices for maintenance and leveling, users can ensure their Precision Granite Platforms maintain their Grade 0 accuracy for decades.

Post time: Nov-10-2025