As the semiconductor industry aggressively pursues sub-2nm process nodes, the margin for mechanical error has virtually vanished. In this high-stakes environment, the stability of the process chamber is no longer a secondary concern; it is the primary bottleneck for yield. At ZHHIMG, we are observing a fundamental shift in how global OEMs approach the structural integrity of semiconductor capital equipment.

The Physics of Silence: Advanced Vibration Damping Techniques

In modern wafer fabrication, vibrations that were once considered “background noise” are now catastrophic. Whether it is the micro-oscillations from a facility’s HVAC system or the internal inertia of a high-speed scanning stage, uncontrolled energy directly translates to overlay errors and blurred patterns.

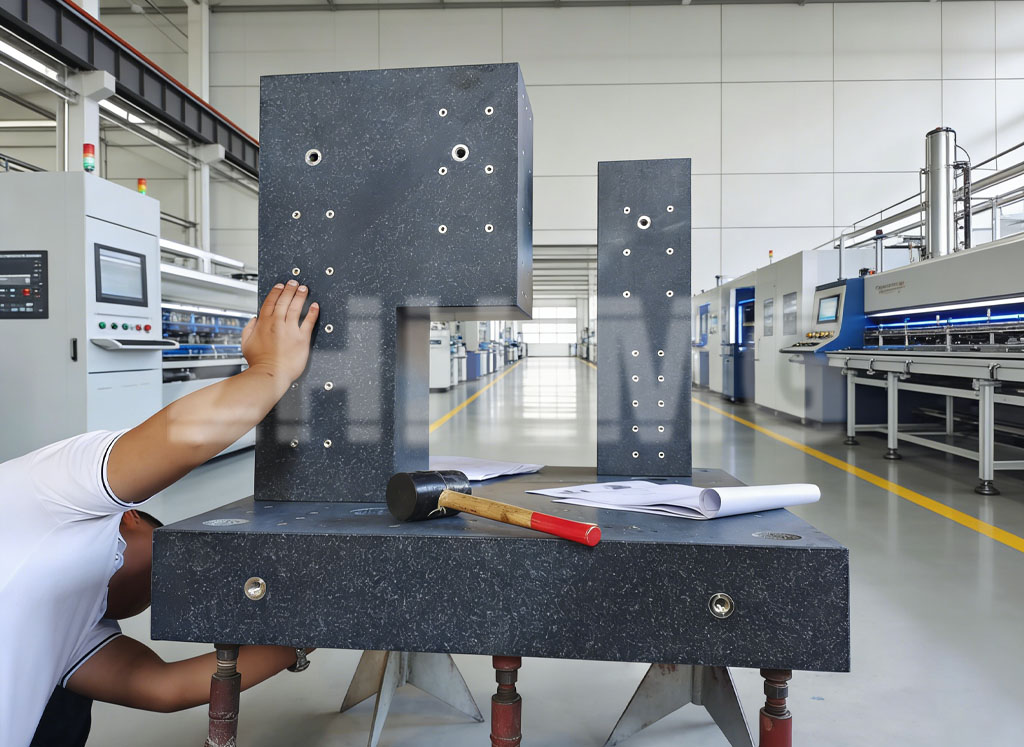

Current vibration damping techniques in semiconductor manufacturing have evolved into a multi-layered architecture. While passive damping—utilizing high-mass materials like mineral casting or precision granite—remains the foundation, we are seeing a surge in active damping integration.

Active systems utilize piezoelectric actuators and real-time sensors to “cancel” vibrations by generating counter-frequencies. However, the effectiveness of active systems is inherently limited by the base material’s damping ratio. This is where ZHHIMG’s expertise in high-damping structural materials becomes critical. By combining active electronics with a naturally inert granite or composite base, we provide a “Quiet Zone” where nano-positioning can occur without interference.

The Rise of Frictionless Motion: Air Bearing Technology

The demand for higher throughput has pushed traditional mechanical bearings to their limits. Friction leads to heat, and heat leads to thermal expansion—the enemy of precision. This has led to the widespread adoption of air bearing technology for precision stages.

Air bearings support a load on a thin film of pressurized air, typically only a few microns thick. Because there is no physical contact, there is zero static friction (stiction). This allows for:

-

Hysteresis-Free Motion: Ensuring that the stage returns to the exact same nanometer coordinate every time.

-

Velocity Constancy: Critical for scanning applications like E-beam inspection where even the slightest “cogging” of a mechanical bearing would distort the image.

-

Extreme Longevity: Since there are no touching parts, there is no wear and no particulate generation, making them ideal for Class 1 cleanroom environments.

At ZHHIMG, we manufacture the ultra-flat granite surfaces that serve as the guide-ways for these air bearings. To function correctly, these surfaces must be lapped to a flatness measured in fractions of a light wavelength.

Trends in Semiconductor Capital Equipment: 2026 and Beyond

As we move through 2026, the trends in semiconductor capital equipment are characterized by “The Three Pillars”: Modularization, Sustainability, and Thermal Control.

-

Modular Platform Design: OEMs are looking for “plug-and-play” base modules. Instead of designing a new base for every tool, they are utilizing standardized ZHHIMG precision foundations that can be adapted for lithography, metrology, or etching.

-

Thermal Management: As EUV (Extreme Ultraviolet) light sources generate immense heat, the machine base must act as a massive heat sink. We are integrating complex cooling channels directly into our mineral and granite components to maintain a delta of $<0.01^\circ\text{C}$.

-

Vacuum Compatibility: With more processes moving into high-vacuum environments, the materials used must have zero outgassing. Our specialized granite and ceramic processing ensures that the integrity of the vacuum is never compromised by the structural foundation.

Strategic Partnership with ZHHIMG

ZHHIMG is not merely a component manufacturer; we are a strategic partner in the motion control supply chain. Our facility in China works in close coordination with engineering teams in Silicon Valley and Eindhoven to solve the most difficult stability challenges in the industry.

By leveraging our proprietary lapping techniques and our deep understanding of vibration damping techniques, we enable our clients to push the boundaries of Moore’s Law. Whether you are developing a next-generation ALD (Atomic Layer Deposition) tool or a high-speed wafer prober, the foundation starts with ZHHIMG.

Conclusion

The evolution of semiconductor manufacturing is a race against the laws of physics. As the industry moves toward 2026, the focus on air bearing precision and advanced damping will only intensify. Staying ahead of these trends requires a foundation—both literally and figuratively—built on expertise and innovation.

Post time: Jan-26-2026