In the realm where length is measured in millionths of an inch and precision is the only standard—the same demanding environment that drives ZHHIMG®’s manufacturing—there is one tool that reigns supreme: the Gauge Block. Known universally as Jo Blocks (after their inventor), slip gauges, or Hoke blocks, these finely ground and polished metal or ceramic pieces are the bedrock of all dimensional metrology. They are not merely tools; they are the physical embodiment of a specific length, serving as the ultimate reference point for calibrating everything from micrometers and calipers to sine bars and dial indicators across every major industry.

A Revolution in Measurement: The History of the Jo Block

Before 1896, mechanical workshops relied on bespoke, shop-specific measuring tools—custom-filed gauges and specialized “Go/No-Go” checks. While functional, this system lacked the crucial element of universal standardization.

The game-changing concept was introduced by the brilliant Swedish machinist Carl Edvard Johansson in 1896. Johansson’s revolutionary idea was to create individual, ultra-precise length standards that could be stacked together seamlessly. This innovation meant that a small set of meticulously crafted blocks could be combined to achieve thousands of different, highly accurate lengths—a flexibility previously unheard of. Johansson’s gauge blocks effectively standardized the length reference for the industrial world.

The Magic of Adhesion: Understanding “Wringing”

The most remarkable feature of a gauge block is its ability to adhere tightly to another block with minimal dimensional error. This phenomenon is called wringing. It is achieved by sliding two blocks together, causing their microscopically flat surfaces to bond securely, essentially eliminating any air gap and minimizing the joint’s contribution to overall error.

This unique property is what gives gauge blocks their incredible utility. For example, by utilizing just three blocks from a typical set, one can achieve a thousand different lengths—say, from 3.000 mm to 3.999 mm in 0.001 mm increments. It’s a profound engineering trick that makes them indispensable.

The Four Steps to Perfect Wringing

Achieving this precision bond is a meticulous, four-step skill:

- Initial Cleaning: Start by gently wiping the gauge blocks on an oiled conditioning pad.

- Oil Removal: Next, wipe the blocks across a dry pad to remove any excess oil, leaving only a microscopic film.

- Cross Formation: Place one block perpendicularly across the other and apply moderate pressure while sliding them together until they form a cross.

- Alignment: Finally, rotate the blocks until they are perfectly aligned, locking them into a robust, high-precision stack.

This careful technique underscores the necessity of cleanliness, controlled pressure, and precise alignment to achieve the secure and accurate connection required for metrological work. The success of this adhesion is officially defined as “wringability,” which requires a surface finish of 1 microinch 0.025 μm m) AA or better, and a flatness of at least 5 μin (0.13 μm).

Best Practices: Protecting Your Length Standards

Due to their extreme precision, gauge blocks require vigilance in handling and storage. Professionals understand that the longevity and accuracy of a set depend entirely on adherence to best practices:

- Corrosion Prevention: Immediately after use, blocks must be re-oiled or greased. Corrosion is the primary enemy of dimensional stability, and neglecting this step will quickly destroy the surface accuracy.

- Handling: Always handle the blocks by their sides, never touching the critical measuring surfaces. Body heat and skin oils transfer to the block, causing temporary expansion and permanent corrosion over time.

- Temperature Control: Gauge blocks are most accurate when measured at the internationally defined reference temperature of 20℃ (68°F). Any measurement performed outside of this controlled environment requires thermal compensation.

Conclusion: The Precision ZHHIMG® Builds On

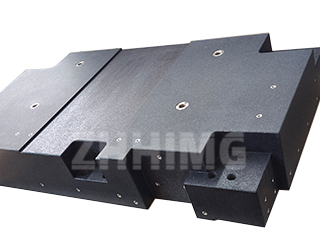

Gauge blocks are the unsung heroes that validate the world of precision manufacturing. They are the immutable reference point against which ZHHIMG® calibrates its advanced measurement tools, ensuring that our granite, ceramic, and metal components achieve the micrometer and nanometer tolerances required for the world’s most advanced machines. By respecting the history and adhering to the best practices of these indispensable tools, we collectively uphold the standard of precision that drives technological progress.

Post time: Nov-05-2025