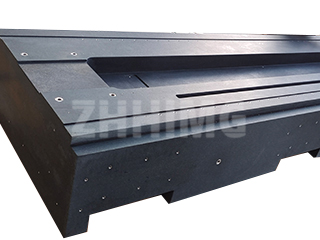

The seemingly simple question of whether size impacts the difficulty of precision control in granite platforms often receives an intuitive but incomplete “yes.” In the realm of ultra-precision manufacturing, where ZHHIMG® operates, the difference between controlling the accuracy of a small, benchtop 300 × 200 mm granite surface plate and a massive 3000 × 2000 mm machine base is not merely quantitative; it is a fundamental shift in engineering complexity, demanding entirely different manufacturing strategies, facilities, and expertise.

The Exponential Rise of Error

While both small and large platforms must adhere to stringent flatness specifications, the challenge of maintaining geometric accuracy scales exponentially with size. A small platform’s errors are localized and easier to correct through traditional hand lapping techniques. Conversely, a large platform introduces several layers of complexity that challenge even the most advanced manufacturers:

- Gravity and Deflection: A 3000 × 2000 mm granite base, weighing many tons, experiences significant self-weight deflection across its span. Predicting and compensating for this elastic deformation during the lapping process—and ensuring the required flatness is achieved under the eventual operating load—requires sophisticated finite element analysis (FEA) and specialized support systems. The sheer mass makes repositioning and measurement immensely difficult.

- Thermal Gradients: The larger the volume of granite, the longer it takes to reach full thermal equilibrium. Even small temperature variations across the surface of a large base create thermal gradients, causing the material to subtly warp. For ZHHIMG® to guarantee nanometer-level flatness, these massive components must be processed, measured, and stored within specialized facilities—such as our 10,000 ㎡ climate-controlled workshops—where temperature variation is tightly controlled across the entire volume of the granite.

Manufacturing and Metrology: A Test of Scale

The difficulty is deeply rooted in the manufacturing process itself. Achieving true precision on a large scale requires tools and infrastructure that few in the industry possess.

For a small 300 × 200 mm plate, expert manual lapping is often sufficient. However, for a 3000 × 2000 mm platform, the process demands ultra-large capacity CNC grinding equipment (like ZHHIMG®’s Taiwan Nanter grinding machines, capable of handling 6000 mm lengths) and the ability to move and handle components weighing up to 100 tons. The scale of the equipment must match the scale of the product.

Furthermore, metrology—the science of measurement—becomes intrinsically more difficult. Measuring the flatness of a small plate can be done relatively quickly with electronic levels. Measuring the flatness of a massive platform requires advanced, long-range instruments like Renishaw Laser Interferometers and requires the entire surrounding environment to be absolutely stable, a factor addressed by ZHHIMG®’s vibration-damped floors and anti-seismic trenches. Errors of measurement on a small scale are marginal; on a large scale, they can compound and invalidate the entire component.

The Human Element: Experience Matters

Finally, the human skill required is profoundly different. Our experienced craftsmen, with over 30 years of manual lapping experience, can achieve nano-level precision on both scales. However, achieving this level of uniformity across a vast 6 ㎡ surface requires a level of physical endurance, consistency, and spatial intuition that transcends standard craftsmanship. It is this combination of world-class infrastructure and unrivaled human expertise that ultimately differentiates a supplier capable of handling both the small and the extremely large.

In conclusion, while a small granite platform tests the precision of material and technique, a large platform fundamentally tests the entire manufacturing ecosystem—from material consistency and facility stability to the capacity of the machinery and the profound experience of the human engineers. The scaling of size is, in effect, the scaling of engineering challenge.

Post time: Oct-21-2025