In modern metrology and precision manufacturing, the foundation of every measurement or production system is no longer a passive structure—it is a key factor that directly influences accuracy, repeatability, and long-term reliability. As industries ranging from semiconductor fabrication to high-precision assembly continue to demand micron-level tolerances, precision granite has emerged as the material of choice for machine bases, coordinate measuring machines (CMMs), and critical inspection platforms.

Granite offers a unique combination of properties that support high-precision engineering: superior stiffness, excellent vibration damping, low thermal expansion, and long-term dimensional stability. Selecting the appropriate type of granite and understanding its thermal behavior are therefore central to designing machine bases that consistently deliver reliable performance in demanding environments.

Types of Granite Used for Metrology Applications

Not all granite is created equal. For metrology-grade applications, engineers carefully select granite based on mineral composition, density, grain structure, and internal homogeneity. Common types of granite used in precision machinery include:

-

Black Granite: Known for high density and low porosity, black granite provides excellent vibration damping and thermal stability. Its uniform grain structure minimizes internal stresses, making it ideal for CMM bases and surface plates.

-

Gray Granite: Offers good machinability while maintaining reasonable thermal stability. It is often used for inspection tables and measurement fixtures where ultra-high damping is less critical.

-

Blue Granite / K2 Granite: Sometimes used for high-precision laboratory components, valued for consistent microstructure and wear resistance.

Precision granite manufacturers implement rigorous material selection processes, often sourcing blocks that meet stringent internal criteria for homogeneity and absence of microfractures. This ensures that final machine bases or surface plates meet exacting flatness and stability requirements.

Thermal Stability of Granite Components

Thermal expansion can be a silent but significant source of measurement error in precision machinery. Unlike metals such as cast iron or steel, granite has a low coefficient of thermal expansion, typically ranging between 4–8 × 10⁻⁶ /°C, depending on the specific mineral composition. This low expansion rate allows granite components to maintain their dimensional integrity across temperature variations commonly found in industrial environments.

In applications like CMMs, even minimal thermal distortion can cause probe misalignment or inaccurate scanning results. Precision granite components, with their superior thermal stability, ensure that reference surfaces remain consistent over time, supporting reliable measurements without frequent recalibration. Moreover, high-quality granite naturally resists thermal cycling fatigue, which can degrade other materials under repeated temperature changes.

Comparison of Granite and Cast Iron Machine Bases

For decades, cast iron was the standard material for machine bases due to its high stiffness, low cost, and ease of casting. While cast iron still finds use in many conventional machining environments, it exhibits several limitations in ultra-precision applications:

-

Vibration Damping: Granite outperforms cast iron in dissipating vibrational energy, reducing resonance and improving stability in dynamic measurement or motion systems.

-

Thermal Behavior: Cast iron expands more quickly with temperature changes, introducing geometric errors in high-precision setups. Granite’s low thermal expansion provides a more stable reference frame.

-

Long-Term Stability: Granite remains dimensionally stable over decades with minimal maintenance, whereas cast iron can develop stress-related distortions over time.

As a result, industries that require high-precision positioning and measurement increasingly favor granite-based machine bases, often combined with epoxy or polymer concrete composites for enhanced design flexibility.

Precision Granite Manufacturers in the United States

The United States hosts several leading precision granite manufacturers that supply metrology, semiconductor, aerospace, and automation industries. These manufacturers differentiate themselves through:

-

Material Expertise: Selecting and testing granite blocks for uniformity, density, and microstructure.

-

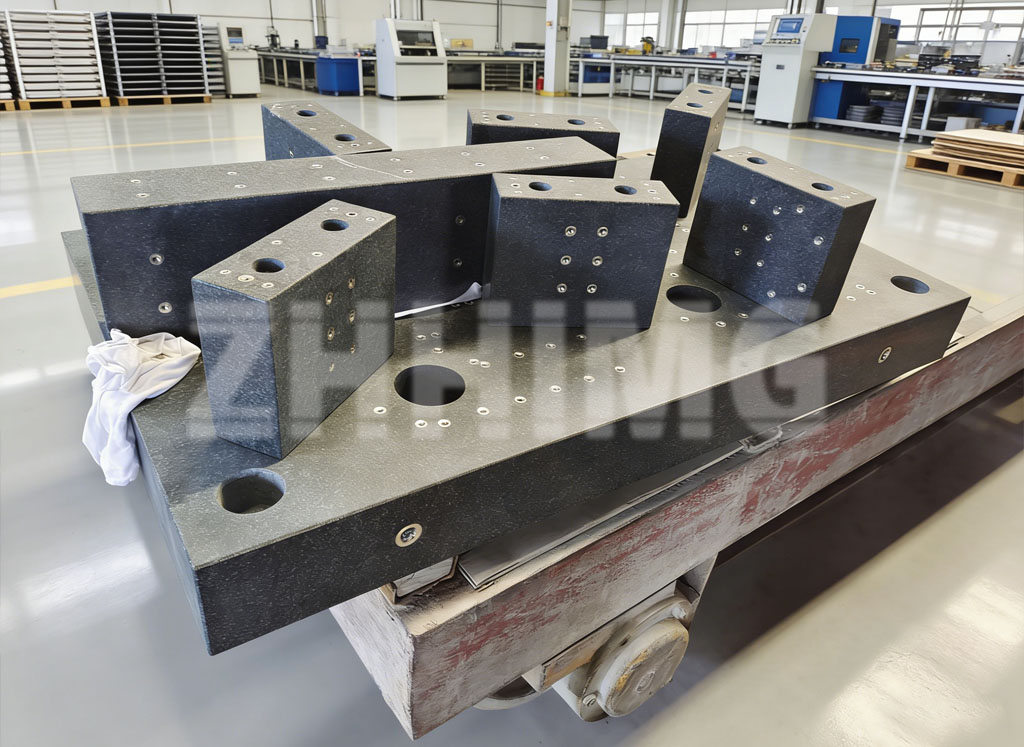

Advanced Machining: Employing CNC grinding, lapping, and hand scraping to achieve sub-micron flatness and alignment.

-

Metrology Integration: Conducting in-house calibration and verification to meet international granite surface plate standards (ISO, DIN, ASME).

-

Customization: Providing tailored solutions for CMM bases, inspection tables, and automation platforms with integrated features such as mounting points, channels, and vibration damping elements.

Manufacturers that combine high-quality raw material selection with precise machining and metrological validation offer machine bases that perform reliably over decades, supporting both OEM equipment builders and end users.

Material Selection as a Strategic Advantage

Choosing the right granite type and manufacturer is not merely a technical decision—it is a strategic one. Machine base performance directly affects measurement accuracy, production quality, and equipment uptime. Working with established precision granite manufacturers ensures:

-

Reduced calibration frequency

-

Consistent measurement accuracy

-

Enhanced system lifespan

-

Lower total cost of ownership

As industries push toward tighter tolerances and higher automation densities, the role of granite machine bases and precision components becomes increasingly central to operational excellence.

Conclusion

Precision granite has solidified its role as the material of choice for metrology-grade machine bases, surface plates, and high-accuracy components. Its superior vibration damping, thermal stability, and long-term reliability distinguish it from traditional cast iron structures. Selecting the right type of granite and partnering with experienced manufacturers—particularly in the United States—ensures that precision engineering systems can meet the exacting demands of today’s industrial and laboratory environments.

At ZHHIMG, our expertise in precision granite manufacturing and our commitment to international standards allow us to provide machine bases, CMM foundations, and granite components that meet the highest levels of metrology and automation accuracy. As the industry continues to advance, granite will remain the foundation upon which the next generation of precision equipment is built.

Post time: Jan-27-2026