Amidst increasingly fierce competition in the global manufacturing industry, precise measurement plays a key role in improving product quality, optimizing production efficiency, and driving technological innovation. As a leading company in precision measurement, ZHHIMG is committed to providing high-performance, precision granite measurement platforms to customers worldwide, enabling high-precision measurement and reliable inspection across various industries.

Excellent Material Advantages

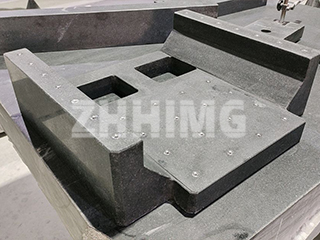

ZHHIMG’s precision granite measurement platforms are made of natural granite, a natural rock formed by geological sedimentation and characterized by exceptional stability and durability. Natural granite’s internal stresses are dissipated over time, resulting in a stable structure and resistance to deformation, enabling it to maintain high precision over time. Compared to traditional cast iron platforms, they offer minimal accuracy degradation, require less maintenance, and offer higher measurement reliability.

Granite also offers excellent wear resistance, ensuring the platform maintains a flat surface over long-term use, ensuring consistent measurement accuracy. Furthermore, granite has extremely low thermal conductivity and coefficient of thermal expansion, making it minimally affected by ambient temperature fluctuations and capable of reliable operation in both normal and non-constant temperature environments. Its excellent internal damping properties effectively absorb external vibrations, ensuring accurate measurement data. Granite is also non-conductive and anti-magnetic, making it safe for use in electromagnetically sensitive measurement environments.

Advanced Processing and Precision Control

To fully leverage the advantages of granite, ZHHIMG employs precision machining technology to achieve ultra-high flatness and geometric accuracy on its platforms. Five-axis nano-grinding technology achieves an ultra-flat surface with a flatness of ≤1μm/㎡, providing a stable benchmark for high-precision measurement. The platform’s straightness, perpendicularity, and parallelism errors are all controlled within a range of ≤2μm/m, meeting the stringent geometric accuracy requirements of high-dynamic precision equipment.

Each platform undergoes rigorous quality testing before shipment, including multiple indicators such as flatness, straightness, and perpendicularity, to ensure compliance with international standards. Our rigorous testing process and traceable test reports provide customers with reliable product quality assurance.

Application Value Across Multiple Industries

Due to its stable and reliable performance, ZHHIMG’s precision granite measurement platforms have been widely adopted in various industries:

Semiconductor Manufacturing: Used in key areas such as nanometer-level positioning stages in lithography machines and wafer inspection modules, they ensure precise positioning and inspection during the semiconductor production process, ensuring improved product yield.

Aerospace: Used in applications such as satellite inertial navigation test benches and spacecraft component inspection tooling, they meet high-precision and high-reliability requirements and provide technical support for the aerospace industry.

Medical Research: Serving as a key support for CT/MRI equipment bases and biological testing stages, they ensure stability and accuracy in medical diagnostics and scientific research.

Smart Manufacturing: Used as calibration bases for industrial robots and core platforms for automated inspection systems, they provide a reliable measurement benchmark for smart manufacturing, improving production efficiency and product quality.

International Certifications and Customer Trust

ZHHIMG’s precision granite measurement platforms are ISO 8512-2:2016 certified and comply with JIS B7516 Level 0 standards. They also support accuracy traceability and thermodynamic simulation analysis. Our products have successfully served over 100 companies worldwide, including semiconductor manufacturing giants, testing organizations for listed companies, and national key laboratories. Typical application cases demonstrate an increase in wafer inspection yield to 99.999% and a 60% reduction in testing cycles for university laboratories. This customer recognition and positive feedback fully demonstrate the platform’s reliability and technical advantages.

Professional Consulting and Customization Services

ZHHIMG offers comprehensive technical consulting services to help customers select the most suitable measurement platform. We also provide customized solutions tailored to specific needs, providing personalized high-precision measurement support. ZHHIMG’s professional team provides attentive guidance throughout the selection, installation, and operation process, ensuring every customer has the best measurement experience.

Contact Us

If you are looking for a high-precision and highly stable measurement platform, ZHHIMG’s precision granite measurement platform is the ideal choice. Feel free to contact us for professional consultation or customized solutions. Together, we can advance precision measurement technology and create greater value for your business.

Post time: Sep-16-2025