In the world of precision engineering, the granite platform is the ultimate foundation for accuracy. It is a universal tool, yet its application focus shifts fundamentally depending on whether it resides in a dedicated metrology lab or on a dynamic industrial production floor. While both environments demand stability, the core differences lie in the required accuracy grade, purpose, and operating environment.

The Precision Pursuit: Measurement and Testing Industry

When a precision granite platform is utilized in a measurement or testing industry setting—such as a national metrology institute, a primary calibration house, or a specialized aerospace quality control lab—its focus is exclusively on Absolute Metrology and Calibration.

- Accuracy Grade: These applications almost universally require the highest level of precision, typically Grade 00 or the ultra-high-precision Grade 000 (often referred to as Laboratory Grade AA). This stringent flatness guarantees that the surface plate itself introduces negligible error into the measurement equation.

- Purpose: The granite serves as the master reference standard. Its primary function is to calibrate other tools (like height gauges, micrometers, or electronic levels) or to provide the static base for high-end instruments, such as Coordinate Measuring Machines (CMMs) or optical comparators.

- Environment: These platforms operate in highly controlled, often temperature-stabilized environments (e.g., 20 ± 1℃) to minimize the effect of thermal expansion, ensuring that the granite’s intrinsic stability translates into absolute dimensional accuracy.

The Durability Drive: Industrial Production and Manufacturing

In contrast, the granite platform deployed on an industrial production or workshop floor faces a different set of challenges and priorities. Here, the focus shifts to Process Control and Durability.

- Accuracy Grade: These applications typically use Grade 0 (Inspection Grade A) or Grade 1 (Workshop Grade B). While still highly precise, these grades offer a balance between accuracy and cost-effectiveness, acknowledging the higher wear rate of a busy manufacturing environment.

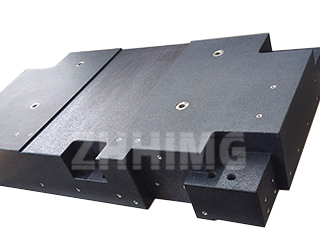

- Purpose: The granite’s role is not to calibrate master tools, but to provide a robust, stable base for in-process inspection, assembly, and layout. It serves as the physical foundation for machinery itself, such as wafer processing equipment, automated assembly lines, or high-speed laser engraving systems. In this capacity, the focus is on the granite’s superior vibration damping properties and stiffness to maintain dynamic positional accuracy during operation.

- Environment: Production environments are often less controlled, exposing the platform to greater temperature fluctuation, airborne debris, and higher physical use. The granite’s inherent resistance to rust and corrosion makes it ideal for these demanding, day-to-day conditions where a metal surface plate would quickly degrade.

ZHHIMG®’s Commitment to Dual Focus

As a leading global supplier, ZHONGHUI Group (ZHHIMG®) understands that the true value of a precision granite platform lies in matching its construction to its intended focus. Whether supplying an ultra-precise, finely finished platform for a university research lab, or a highly durable machine base for a factory automation line, the underlying commitment to the globally recognized standards like Federal Specification GGG-P-463c remains constant. We ensure that every platform, regardless of its grade, leverages the stability of our ZHHIMG® Black Granite to deliver reliability where it matters most: at the foundation of precise measurement and manufacturing.

Post time: Oct-22-2025