In the fast-paced world of electronics manufacturing, where circuits are shrinking and complexity is soaring, the demand for precision has never been higher. The quality of a printed circuit board (PCB) is the foundation of any electronic device, from a smartphone to a medical scanner. This is where an often-overlooked hero emerges: the precision granite platform. At ZHONGHUI Group (ZHHIMG®), we’ve seen firsthand how this seemingly simple material has become the silent, unmoving bedrock for critical inspection and manufacturing processes in the electronics industry, particularly for PCB testing. The applications are diverse, but they all share a common need for a stable, ultra-flat, and reliable base.

The Core Challenge of PCB Manufacturing

PCBs are the nervous system of modern electronics. They are a delicate network of conductive pathways, and any flaw—a tiny scratch, a misaligned hole, or a minor warp—can render a component useless. As circuits become more compact, the tools used to inspect them must be orders of magnitude more precise. This is where the core challenge lies: how do you ensure perfect accuracy when the very machines doing the inspection are subject to thermal expansion, vibration, and structural deformation?

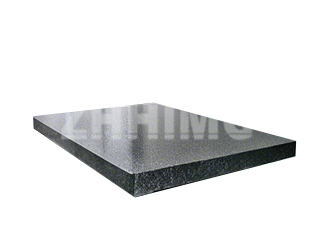

The answer, for many of the world’s leading electronics manufacturers, lies in the unique physical properties of granite. Unlike metals, which are highly susceptible to thermal changes and vibrations, granite offers a level of stability that is unparalleled. Our ZHHIMG® Black Granite has a low coefficient of thermal expansion and excellent vibration dampening properties, making it the ideal material for a stable metrology base. This allows inspection machines to operate with true accuracy, uncorrupted by environmental noise.

Key Applications in PCB and Electronics Testing

Precision granite platforms from ZHHIMG® are integral to several key stages of electronics manufacturing and quality control:

1. Automated Optical Inspection (AOI) & X-ray Inspection: AOI and X-ray machines are the first line of defense in quality control. They rapidly scan PCBs to detect flaws like short circuits, opens, and misaligned components. These systems rely on a perfectly flat reference plane to ensure that the image captured is free of distortion. A granite base provides this ultra-flat, stable foundation, ensuring that the machine’s optics or X-ray source and detector remain in a fixed, precise relationship. Our granite platforms can be manufactured with a flatness of just a few microns, and even at the nanometer level for the most demanding applications, thanks to our experienced craftsmen who possess over 30 years of hand-lapping expertise.

2. PCB Drilling Machines: Creating the thousands of tiny holes on a PCB requires extreme precision. The drilling machine’s entire structure, including the drilling head and the XY table, must be built on a foundation that will not warp or shift. Granite provides this stability, ensuring that every hole is drilled in the exact location specified in the design file. This is particularly critical for multilayer PCBs, where misaligned holes can ruin the entire board.

3. Coordinate Measuring Machines (CMMs) & Vision Measuring Systems (VMS): These machines are used for dimensional verification of PCBs and other electronic components. They require a base with exceptional geometrical accuracy. Our granite platforms serve as the main base for CMMs, providing the perfect reference plane against which all measurements are taken. The inherent stiffness of granite ensures that the base doesn’t flex under the weight of the machine, maintaining a consistent reference for the measurement probe.

4. Laser Processing & Etching Machines: High-power lasers are used for cutting, etching, and marking circuit boards. The laser’s path must be incredibly stable to ensure a clean, precise cut. A granite base provides the necessary vibration dampening and thermal stability to keep the laser head and the workpiece perfectly aligned throughout the process.

The ZHHIMG® Advantage in Electronics

Our partnerships with electronics giants and our commitment to a Quality Policy that states, “The precision business can’t be too demanding,” are what set us apart. We understand that in the electronics sector, there is No cheating, No concealment, No misleading when it comes to quality.

Our 10,000m2 climate-controlled workshop and sophisticated measurement tools, including Renishaw laser interferometers, ensure that every granite base we produce is perfectly tailored to the client’s needs. We’re not just a supplier; we’re a collaborative partner in advancing technology. In an industry where a fraction of a millimeter can be the difference between success and failure, ZHHIMG® provides the stable, accurate, and reliable foundation that the electronics industry relies on to build the future.

Post time: Sep-28-2025