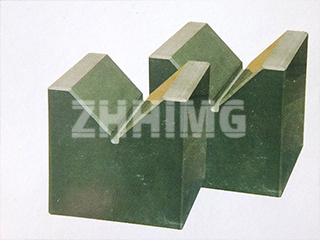

When it comes to precision measurement tools, Granite V-Blocks stand out for their unmatched stability, durability, and accuracy. Crafted from high-quality natural granite through advanced machining and hand-finishing processes, these V-blocks deliver superior performance for industrial and laboratory applications.

Why Choose Granite V-Blocks?

✔ Exceptional Stability & Durability – Made from dense, wear-resistant granite, our V-blocks maintain structural integrity even under heavy loads and temperature variations.

✔ High Precision & Longevity – Ideal for inspecting precision instruments, mechanical parts, and tooling, granite V-blocks ensure consistent accuracy over time without deformation.

✔ Corrosion & Magnetic Resistance – Unlike metal alternatives, granite is non-metallic, non-magnetic, and resistant to rust, acids, and alkalis, making it perfect for sensitive environments.

✔ Minimal Maintenance – Granite’s natural hardness prevents wear and tear. Even accidental impacts only cause minor surface chips, without affecting performance.

✔ Superior to Metal Alternatives – Compared to cast iron or steel, granite V-blocks provide better stability and retain calibration for years, ensuring reliable measurements.

Applications of Granite V-Blocks

- Precision inspection of gauges, bearings, and cylindrical parts

- Ideal reference surface for metrology labs and CNC machining

- Stable support for high-accuracy tool alignment

Trusted by Industries Worldwide

Our granite V-blocks are sourced from premium natural stone, aged over millions of years for maximum stability. Rigorously tested for quality, they guarantee high-precision performance in demanding environments.

Upgrade your measurement process with Granite V-Blocks—where precision meets durability!

Post time: Jul-31-2025