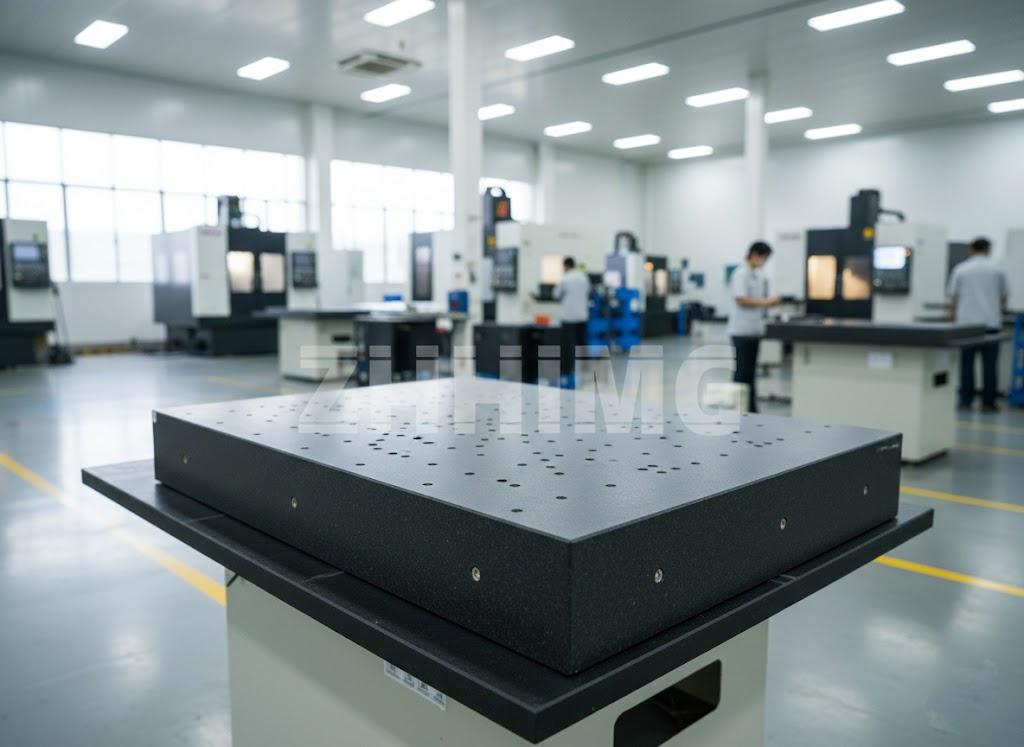

For decades, the foundation of ultra-precision measurement and machining—the metrology platform—has been anchored by two primary materials: granite and cast iron. While both serve the crucial function of providing a stable, flat reference plane, the question of which material offers the superior long-term performance and extended service life is paramount for industries pushing the boundaries of nanotechnology, semiconductor manufacturing, and advanced optics. As operators for ZHONGHUI Group (ZHHIMG®), a global leader pioneering the future of ultra-precision components, we delve deep into the intrinsic properties that define the operational lifespan of both precision granite platforms and traditional cast iron surfaces.

The Unmatched Durability of Precision Granite

To understand the longevity of a precision platform, one must first examine the material’s fundamental properties. ZHHIMG® specifically utilizes the proprietary ZHHIMG® Black Granite, a material that fundamentally redefines the standard for material stability. Unlike lower-density materials often misrepresented in the market, our black granite boasts an exceptionally high density, reaching approximately 3100 kg/m³. This is a critical factor, as high density minimizes internal voids and maximizes stiffness, directly contributing to long-term stability.

The core advantage of granite, particularly ZHHIMG®’s material, lies in its superior resistance to wear and its inherent material composition. Granite is composed of hard, interlocked minerals, primarily quartz, feldspar, and mica. This structure gives it an extremely high hardness (Mohs hardness scale often between 6 and 7), making it highly resistant to abrasion from sliding measuring instruments or component placement.

In contrast to cast iron, granite is non-magnetic and boasts a near-zero coefficient of thermal expansion compared to metals. Cast iron, while rugged, is susceptible to magnetic interference and, critically, rust and corrosion. Over time, a cast iron platform requires meticulous maintenance—frequent oiling and climate control—to prevent oxidation, which directly degrades the flatness and surface integrity. Granite, being chemically inert, requires only routine cleaning, drastically reducing maintenance downtime and preserving its original geometric accuracy. This intrinsic resistance to environmental degradation is a major contributor to the extended usage lifespan of a granite surface plate.

The Lifespan Defining Factor: Material Stability and Creep

The lifespan of a precision platform is not simply about how long the physical block lasts, but how long it can maintain its guaranteed flatness, often reaching nanometer-level precision (as offered by ZHHIMG® for critical applications).

1. Long-Term Dimensional Stability

Granite’s metamorphic structure means that, provided it has been properly aged and stress-relieved—a rigorous process guaranteed by ZHHIMG®’s adherence to international standards like DIN 876, ASME, and JIS—it exhibits virtually no internal stress relief over time, a phenomenon known as “creep.” This stability is crucial. Even after decades of use, a high-quality granite platform, when routinely calibrated, will maintain its overall dimensional integrity far better than metal structures.

Cast iron, a ferrous alloy, is an inherently stable material when properly cast and annealed. However, it remains susceptible to micro-structural changes and internal stress migration, which can slightly alter the reference plane over an extremely long duration. Furthermore, the risk of surface damage is more acute. While cast iron is tougher against impact, scratches and surface scoring on cast iron require significantly more invasive repair (re-machining or scraping) than the lapping and resurfacing techniques applicable to granite.

2. The Role of ZHHIMG®’s Manufacturing Excellence

The longevity of a granite platform is profoundly influenced by its initial manufacturing quality. ZHHIMG®’s commitment to the quality policy—“The precision business can’t be too demanding”—is evidenced by our manufacturing infrastructure:

-

Massive Production Capability: Our facility, spanning 200,000 m², houses four production lines and utilizes advanced equipment, including massive CNC machines capable of handling single parts up to 100 tons and lengths up to 20 meters. This scale ensures uniform quality across large and complex platforms, such as those used for granite air bearings and granite components in semiconductor equipment.

-

Thermal Control: The dedicated 10,000 m² Constant Temperature and Humidity Workshop, featuring a 1000 mm thick military-grade ultra-hard concrete foundation and surrounding anti-vibration trenches, ensures that the initial lapping and measurement processes are performed in a perfectly stable environment. This foundation quality guarantees the maximum initial accuracy, which in turn extends the period before resurfacing is required.

-

Human Expertise: Our competitive edge is our personnel. Our master lappers, with over 30 years of manual lapping experience, possess the sensitivity to “lap to the nanometer level,” a skill often referred to by customers who call them “walking electronic levels.” This ensures that the platform leaves the factory at its absolute peak performance, maximizing its operational life.

Direct Comparison: Lifespan and Maintenance

When directly comparing the operational lifespan, it’s essential to look beyond the initial purchase.

| Feature | Precision Granite Platform (ZHHIMG®) | Cast Iron Platform |

| Wear Resistance | Extremely High. Highly resistant to abrasion due to mineral hardness. | High, but susceptible to surface scoring and localized wear. |

| Dimensional Creep | Negligible after proper aging and stress relief. Excellent long-term stability. | Low, but metal relaxation can occur over decades. |

| Corrosion/Rust | Non-existent. Chemically inert and requires minimal environmental control. | Highly susceptible to rust and requires constant oiling and controlled humidity. |

| Maintenance | Low. Requires simple cleaning. Re-calibration via resurfacing/lapping is straightforward. | High. Requires constant oiling/wiping to prevent rust. Resurfacing requires complex re-scraping or re-machining. |

| Material Contamination | Non-magnetic, no metallic particles generated. Ideal for cleanroom/semiconductor environments. | Can generate magnetic fields and ferrous dust from wear. |

| Operational Lifespan | Significantly Longer. Often exceeds multiple decades with proper calibration, retaining higher initial accuracy for longer. | Long, but requires stricter environmental control; accuracy degrades faster if maintenance is neglected. |

Conclusion: ZHHIMG® Granite – The Epitome of Longevity and Precision

For applications demanding the highest level of geometric accuracy and long-term stability—such as semiconductor equipment bases, coordinate measuring machines (CMM), and ultra-precision CNC machinery—Precision Granite is the undisputed superior choice for lifespan and total cost of ownership (TCO). While cast iron remains a robust option for certain heavy-duty, less-critical applications, the inherent material science and low maintenance of granite platforms make them the standard bearer for modern metrology.

At ZHHIMG®, our commitment to quality is underpinned by our extensive international certifications (ISO 9001, ISO 45001, ISO 14001, CE) and our partnerships with global institutions like the National University of Singapore, Stockholm University, and various National Metrology Institutes. Our products, from granite surface plates to complex granite air bearing assemblies, are designed to be a permanent, high-precision asset in your production line. We firmly believe that quality and precision define lifespan, and we guarantee that our materials—far exceeding the standards of cheap alternatives—offer a service life that truly makes Zhonghui Group—ZHHIMG® the synonym for industry standards.

Our promise to customers is simple: No cheating, No concealment, No misleading. When you choose ZHHIMG®, you are investing in a precision platform with an operational lifespan engineered for the future of ultra-precision industry.

Post time: Dec-12-2025