In the fast-evolving landscape of advanced manufacturing, precision remains the ultimate frontier. Today, a groundbreaking innovation is set to redefine industry standards: the Precision Marble Three-Axis Gantry Platform, a marvel of engineering that combines natural granite’s inherent stability with cutting-edge mechanical design to achieve micron-level accuracy previously thought unattainable in industrial applications.

The Science Behind the Stability

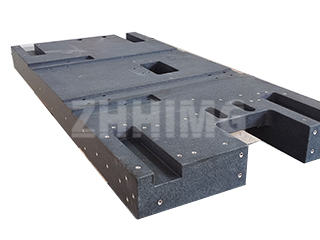

At the heart of this technological leap lies an unexpected material choice: natural granite. The platform’s 1565 x 1420 x 740 mm precision-machined marble base isn’t just a design aesthetic—it’s a scientific solution to the age-old challenge of maintaining stability in high-precision systems. “Granite’s extremely low coefficient of thermal expansion (2.5 x 10^-6 /°C) and exceptional damping characteristics provide a foundation that resists environmental temperature fluctuations and mechanical vibrations far better than traditional metal structures,” explains Dr. Emily Chen, lead mechanical engineer at the Precision Engineering Research Institute.

This natural advantage translates directly to performance metrics that are turning heads across industries. The platform achieves ±0.8 μm repeatability—meaning it can return to any position with deviations smaller than the wavelength of visible light—and ±1.2 μm positioning accuracy after compensation, setting a new standard for motion control systems

Engineering Excellence in Motion

Beyond its stable foundation, the platform’s three-axis gantry design incorporates several proprietary innovations. The X-axis features a dual-drive system that eliminates torsional deformation during high-speed movement, while both X and Y axes deliver 750 mm of effective travel with ≤8 μm straightness in both horizontal and vertical planes. This level of geometric precision ensures that even complex 3D trajectories maintain sub-micron accuracy.

The system’s motion capabilities strike a remarkable balance between speed and precision. While its maximum speed of 1 mm/s may seem modest, it’s optimized for applications requiring fine control and slow scanning—where accuracy matters more than rapid movement. Conversely, the 2 G acceleration capability ensures responsive start-stop performance, critical for maintaining throughput in precision inspection processes.

With a 40 kg load capacity and 100 nm resolution (0.0001 mm), the platform bridges the gap between delicate micro-manipulation and industrial robustness—a versatility that’s generating significant interest across manufacturing sectors.

Transforming Critical Industries

The implications of this precision breakthrough extend across multiple high-tech sectors:

In semiconductor manufacturing, where even nanometer-scale defects can render chips useless, the platform’s stability is revolutionizing wafer inspection and photolithography alignment processes. “We’re seeing defect detection rates improve by 37% in early trials,” reports Michael Torres, senior process engineer at a leading semiconductor equipment manufacturer. “The marble base’s vibration damping has eliminated the micro-wobble that previously obscured sub-50 nm features.”

Precision optical manufacturing is another beneficiary. Lens polishing and assembly processes that once required hours of painstaking manual adjustment can now be automated with the platform’s sub-micron positioning, reducing production times while improving optical performance consistency.

In biomedical research, the platform is enabling breakthroughs in single-cell manipulation and high-resolution microscopic imaging. Dr. Sarah Johnson of Stanford’s Biomedical Engineering Department notes, “The stability allows us to maintain focus on cellular structures for extended periods, capturing time-lapse images that reveal biological processes previously hidden by equipment drift.”

Other key applications include high-precision coordinate measuring machines (CMMs), microelectronics packaging, and advanced scientific research instruments—all areas where the platform’s unique combination of precision, stability, and load capacity addresses longstanding technical limitations.

The Future of Ultra-Precision Manufacturing

As manufacturing continues its relentless push toward miniaturization and higher performance standards, the demand for ultra-precision positioning systems will only intensify. The Precision Marble Three-Axis Gantry Platform represents not just an incremental improvement but a fundamental shift in how precision is achieved—harnessing natural material properties alongside advanced engineering rather than relying solely on complex active compensation systems.

For manufacturers navigating the challenges of Industry 4.0, this platform offers a glimpse into the future of precision engineering. It’s a future where the line between “laboratory precision” and “industrial production” continues to blur, enabling innovations that will shape everything from next-generation electronics to life-saving medical devices.

As one industry analyst put it: “In the world of precision manufacturing, stability isn’t just a feature—it’s the foundation upon which all other advancements are built. This platform doesn’t just raise the bar; it rebuilds it entirely.”

Post time: Oct-31-2025