Precision measurement has always been a cornerstone of manufacturing, but in today’s industrial landscape, its role is becoming more critical than ever. As tolerances tighten, production cycles shorten, and global supply chains demand consistency, manufacturers are placing renewed emphasis on the tools and standards that define measurement accuracy.

From precision measuring tools used on the shop floor to advanced inspection systems in controlled environments, companies are reassessing how measurement foundations impact product quality. In particular, increased attention is being paid to height gauges, evolving metrology standards, and the long-term advantages of granite surface plates as reference platforms.

This renewed focus reflects a broader industry trend: measurement is no longer just a verification step—it is a strategic element of manufacturing reliability.

Precision Measuring Tools Under New Expectations

In many manufacturing environments, precision measuring tools were once selected primarily based on resolution and durability. Today, expectations extend far beyond those criteria.

Modern precision measuring tools must deliver consistent results across shifts, operators, and facilities. They are expected to integrate with digital systems, support traceability, and perform reliably under increasingly demanding audit requirements.

This shift is especially evident in industries such as automotive, aerospace, medical devices, and semiconductor equipment, where measurement uncertainty directly affects compliance and customer acceptance. As a result, manufacturers are taking a more holistic view—evaluating not only the instrument itself, but also the reference surfaces and environmental conditions that influence measurement outcomes.

Height Gauges: Still Essential in a Digital Era

Despite rapid advances in automated inspection and coordinate measuring machines, the height gauge remains one of the most widely used precision measuring tools in manufacturing.

Its continued relevance lies in its versatility. Height gauges are used for:

-

Dimensional inspection

-

Layout and marking

-

Step height and feature measurement

-

Comparative measurements in production environments

Modern digital and electronic height gauges offer improved resolution, data output capabilities, and operator efficiency. However, regardless of technology level, their accuracy is fundamentally dependent on the quality of the reference surface beneath them.

This is where manufacturers are increasingly recognizing that even the most advanced height gauge cannot perform correctly without a stable, flat, and well-maintained surface plate.

Metrology Standards Are Driving Higher Expectations

The growing emphasis on measurement reliability is closely tied to evolving metrology standards. International frameworks such as ISO, ASME, and national metrology institute guidelines continue to raise expectations for traceability, uncertainty management, and documentation.

In audits and customer assessments, manufacturers are now expected to demonstrate not only that instruments are calibrated, but that the entire measurement system—including reference surfaces—meets defined standards.

This includes:

-

Traceable calibration of measuring tools

-

Verified flatness and condition of surface plates

-

Controlled environmental conditions

-

Documented measurement procedures

As metrology standards become more integrated into quality management systems, surface plates and measurement foundations are increasingly scrutinized as part of formal compliance reviews.

Why Reference Surfaces Are Back in Focus

For many years, surface plates were treated as static infrastructure. Once installed, they were rarely questioned unless visible damage occurred. Today, that approach is changing.

Manufacturers are discovering that subtle changes in reference surfaces can introduce systematic errors that affect multiple measuring tools simultaneously. Height gauges, indicators, and even portable measuring devices all rely on the same foundation.

This realization has brought renewed attention to material selection and long-term stability—particularly when comparing traditional materials with modern alternatives.

Advantages of Granite Surface Plates in Modern Metrology

Among available reference surfaces, the advantages of granite surface plates are increasingly recognized in both inspection rooms and advanced production environments.

Granite offers inherent properties that align well with modern metrology requirements:

-

Thermal stability

Granite expands very slowly with temperature changes, helping maintain consistent measurements in environments where temperature cannot be perfectly controlled. -

Long-term dimensional stability

High-quality granite resists wear and maintains flatness over extended service life, reducing the frequency of reconditioning. -

Non-magnetic and corrosion-resistant

These characteristics are particularly valuable when measuring electronic components or using sensitive precision instruments. -

Low maintenance requirements

Unlike metallic surfaces, granite does not require rust prevention treatments or frequent resurfacing.

As metrology standards place greater emphasis on repeatability and uncertainty control, these advantages have made granite surface plates a preferred choice for precision measurement applications.

Height Gauges and Granite Surface Plates: A System Approach

The relationship between height gauges and granite surface plates highlights a broader shift toward system-level thinking in measurement.

Rather than evaluating tools in isolation, manufacturers are increasingly considering how instruments interact with their environment. A high-resolution height gauge placed on an unstable or worn surface plate cannot deliver reliable results, regardless of its specifications.

By pairing height gauges with properly selected and maintained granite surface plates, manufacturers can improve repeatability, reduce operator variation, and support compliance with metrology standards.

This system approach is becoming especially common in inspection rooms supporting automated production lines, where measurement consistency is critical to process control.

Environmental Control and Measurement Confidence

Environmental factors remain a significant influence on measurement performance. Temperature gradients, vibration, and uneven loading can all affect precision measuring tools and reference surfaces.

Granite surface plates perform particularly well in controlled environments, where their natural stability complements modern environmental management practices. As more manufacturers invest in temperature-controlled inspection areas, the benefits of granite become increasingly apparent.

This alignment between material properties and environmental control strategies supports long-term measurement confidence—an essential requirement in regulated industries.

Implications for Quality Management Systems

The growing focus on precision measuring tools, height gauges, and reference surfaces has important implications for quality management systems.

Auditors and customers are increasingly evaluating measurement systems as integrated structures rather than collections of individual instruments. This means that surface plates, stands, and environmental controls are now part of the conversation when discussing measurement capability.

Manufacturers who proactively address these elements are better positioned to demonstrate compliance with metrology standards and reduce the risk of measurement-related nonconformities.

ZHHIMG’s Perspective on Measurement Foundations

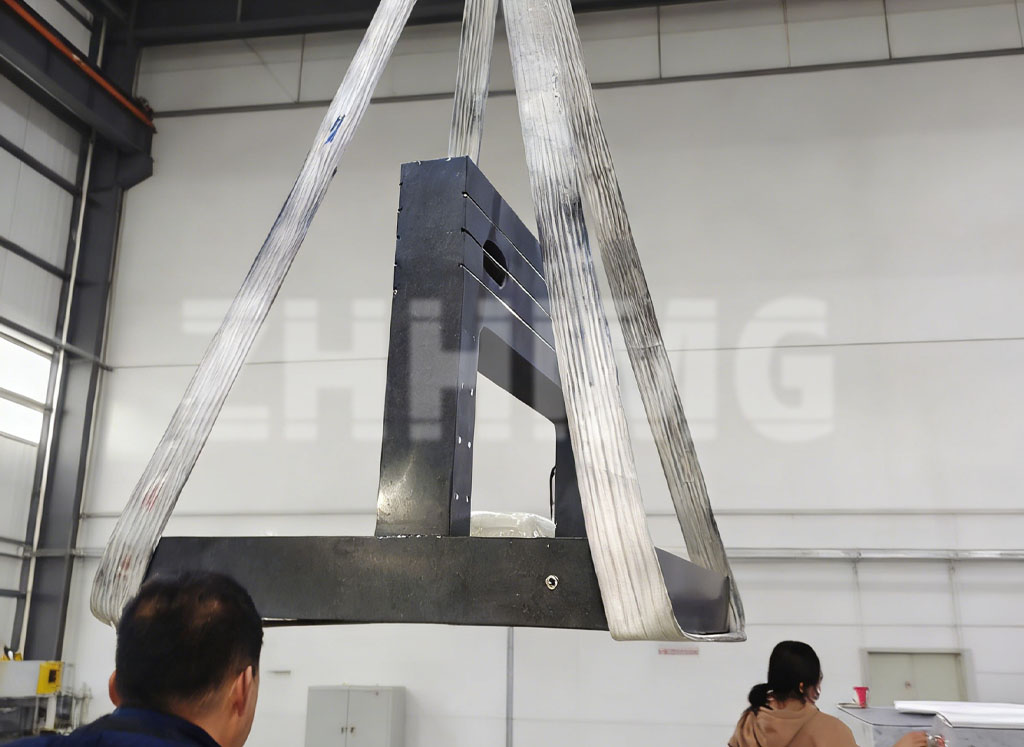

At ZHHIMG, we work with customers who face these evolving expectations across a wide range of precision manufacturing sectors. Through our experience with granite surface plates and precision granite components, we have observed a clear industry trend toward greater awareness of measurement foundations.

Our approach emphasizes not only manufacturing accuracy, but also how granite surface plates support precision measuring tools over their entire service life. By focusing on stability, material quality, and compatibility with modern metrology standards, we help customers build reliable measurement systems rather than isolated solutions.

Looking Ahead

As manufacturing continues to advance, precision measurement will remain a defining factor in quality and competitiveness. The renewed attention on precision measuring tools, height gauges, metrology standards, and the advantages of granite surface plates reflects a broader understanding that measurement accuracy begins at the foundation.

For manufacturers aiming to achieve consistent results, meet international standards, and support long-term process stability, revisiting measurement strategies is no longer optional—it is a strategic necessity.

Post time: Jan-19-2026