The Challenge of Transporting Multi-Ton Accuracy

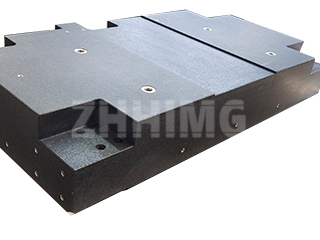

Purchasing a large-scale precision granite platform—especially components capable of supporting a 100-ton load or measuring up to 20 meters in length, as we produce at ZHHIMG®—is a significant investment. A critical concern for any engineer or procurement specialist is the safe delivery of these components. Given their weight, sheer size, and the need to maintain nanometer flatness, how do suppliers mitigate the risk of catastrophic damage from impact and vibration during global logistics?

The answer lies in a highly engineered, multi-layered approach to protection, where the supplier’s commitment to packaging is as critical as the platform’s manufacturing precision.

The Supplier’s Responsibility: Engineered Protective Packaging

At ZHHIMG®, we view the logistics phase as an extension of our quality control. We do not simply “box” a precision component; we engineer a robust, shock-absorbing containment system for transit.

- Custom-Built, Heavy-Duty Crating: The fundamental protective measure is the crate itself. For large granite platforms, we use custom-designed, multi-layered wooden crates constructed from high-strength timber, specifically engineered to manage the component’s massive weight (often thousands of kilograms). These crates are reinforced internally with steel banding and structured to distribute dynamic loads across the entire base.

- Strategic Isolation and Damping: The most crucial element is isolating the granite component from the wooden crate walls. High-density, closed-cell foam or specialized rubber isolation pads are strategically placed at the component’s support points (which we determine based on FEA analysis) to absorb vibration and prevent direct contact with the rigid crate structure. This creates a cushion against impact shock during handling and road transit.

- Surface and Edge Protection: The highly polished, metrology-grade working surface is covered with protective film and cushioned foam sheets. Edges and corners—the most vulnerable points—are reinforced with extra layers of corner protection blocks to prevent chipping or spalling, which could compromise the component’s structural integrity.

- Moisture and Climate Control: For long ocean freight or transit across varied climates, the granite component is sealed inside a vapor barrier bag containing desiccants (moisture absorbers). This protects the material from potential moisture absorption, which could lead to temporary thermal expansion issues upon arrival.

Mitigating Collision Damage: Handling Protocols

While professional packaging is key, safe transport also relies on stringent handling protocols applied both at the port and during final mile delivery:

- Center of Gravity Marking: All large crates are clearly marked with the precise center of gravity (COG) and designated lifting points. This essential detail prevents workers from mis-slinging the crate, which could cause rotational momentum and internal shifting upon lifting.

- Tilt and Shock Indicators: We affix shock indicators and tilt monitoring devices externally on the crates. If the platform experiences excessive impact (G-force) or is tilted beyond a permissible angle, these indicators will visibly change color. This provides immediate, traceable evidence of mishandling, offering protection and clarity for the client upon receipt.

- Orientation Compliance: Crates are explicitly marked with “DO NOT STACK” and clear orientation arrows to ensure the platform remains upright, which is essential for preserving the integrity of its engineered support points.

In conclusion, when procuring high-value, large-scale precision granite platforms, protective packaging is non-negotiable. At ZHHIMG®, our logistics expertise, backed by our Quad-Certified standards, guarantees that the nanometer-level accuracy we achieve in our 10,000 m2 cleanroom is preserved, delivered safely to your door anywhere in the world.

Post time: Oct-13-2025