In the current landscape of high-precision engineering, the transition from traditional mechanical contact to frictionless motion is no longer just a trend—it is a technical necessity. For industries ranging from semiconductor wafer inspection to advanced laser processing, the quest for the “perfect scan” has led engineers back to a fundamental material: natural black granite. When this ancient material is engineered into a Gantry Type Air Bearing Stage, it solves the most persistent challenges in metrology: friction, thermal drift, and mechanical hysteresis.

At ZHHIMG (www.zhhimg.com), we have observed that the most successful ultra-precision systems are not merely a collection of parts, but a holistic synergy between material science and fluid dynamics. The foundation of this performance lies in the interface between a Granite Air Guide Rail and its corresponding Granite Air Slide Block. Unlike steel recirculating ball guides, these components operate on a thin film of pressurized air, typically between 5 to 10 microns thick. This air film acts as a natural filter, averaging out microscopic surface imperfections and providing a level of straightness that mechanical bearings simply cannot replicate.

One of the most significant advantages of using a Granite Air Guide Rail is its inherent dimensional stability. In high-speed scanning applications, metal rails generate heat through friction, leading to thermal expansion and “accuracy drift” over hours of operation. Granite, being an igneous rock with an incredibly low coefficient of thermal expansion, remains indifferent to these temperature fluctuations. When a Granite Air Slide Block glides over this surface, the absence of physical contact means there is zero wear, zero vibration from recirculating balls, and zero need for lubrication—a critical factor for ISO Class 1 cleanroom environments where oil mist or metallic dust would compromise the entire production batch.

However, the precision of a motion system is only as good as its weakest link. This is why the industry is shifting toward the complete Granite assembly with ball screws and rails. While air bearings provide the frictionless “float,” the drive mechanism—often a precision-ground ball screw or a linear motor—must be integrated with extreme care. By mounting these drive components directly onto a precision-lapped granite base, we eliminate the alignment errors that often plague hybrid metal-and-stone systems. This integrated approach ensures that the center of gravity and the center of thrust are perfectly balanced, minimizing the “Abbe error” that can degrade accuracy at high accelerations.

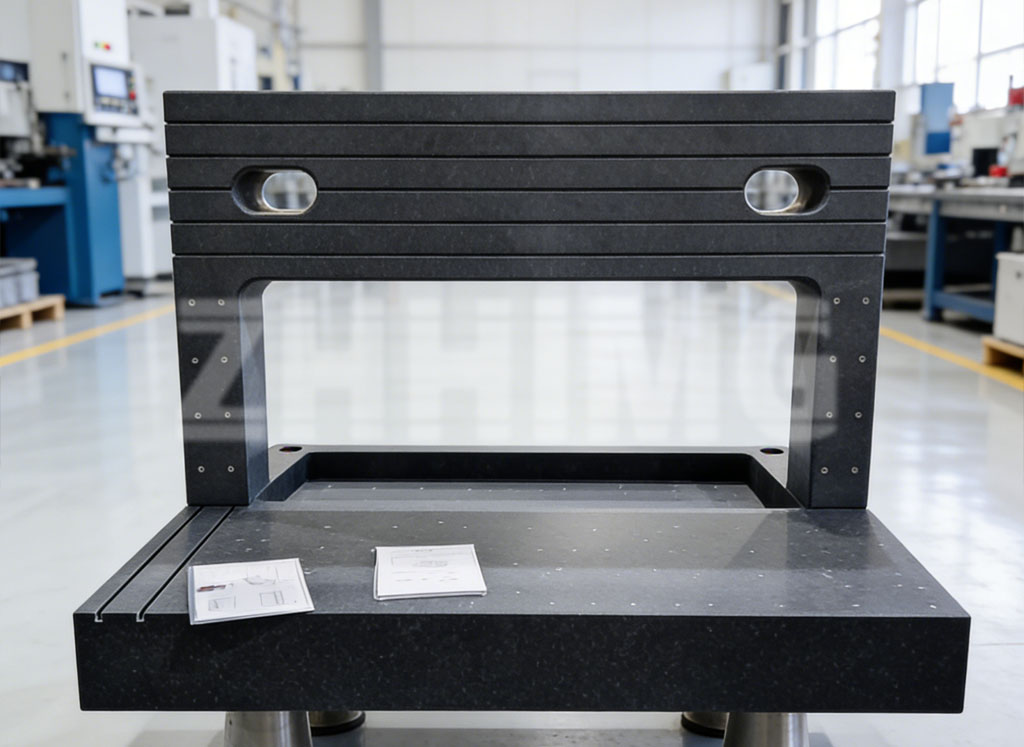

For global OEMs, the choice of a Gantry Type Air Bearing Stage is often driven by the need for high throughput without sacrificing repeatability. In a typical gantry configuration, the dual-drive architecture allows for large-format travel—essential for modern FPD (Flat Panel Display) inspection—while maintaining the structural rigidity provided by the granite cross-beam. The natural damping properties of granite are significantly superior to cast iron or aluminum, allowing the system to “settle” almost instantaneously after a high-speed move. This reduction in settling time directly translates to higher units-per-hour (UPH) for the end-user.

Designing these systems requires a deep understanding of the “error budget.” Every micron counts. When we manufacture a Granite assembly with ball screws and rails, our process involves hand-lapping the granite surfaces to Grade 00 specifications before any mechanical installation occurs. This ensures that the Granite Air Guide Rail provides a perfectly planar reference for the entire motion envelope. The result is a system that offers nanometer-level resolution and sub-micron repeatability, day after day, in the most demanding industrial environments.

As we look toward the future of nanotechnology and 2nm semiconductor nodes, the role of stone-based air bearing technology will only expand. The stability of a Granite Air Slide Block moving silently over a precision rail is a testament to how traditional materials and modern physics can be combined to push the limits of what is measurable. At ZHHIMG, we continue to refine these granite-based solutions, ensuring that our partners have the stable, frictionless foundation they need to build the next generation of technological breakthroughs.

Discover the technical specifications and customization possibilities of our motion platforms at www.zhhimg.com.

Post time: Jan-16-2026