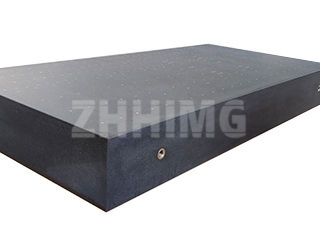

Granite machine components—the precision bases and measuring references used across metrology labs and machine shops—are the undeniable bedrock of high-accuracy work. Crafted from high-density, naturally aged stone like ZHHIMG® Black Granite, these components offer enduring stability, are non-magnetic, rust-proof, and immune to the long-term creep deformation that plagues metallic counterparts. While granite’s innate qualities make it the ideal reference plane for verifying instrumentation and critical machine parts, even this durable material requires meticulous maintenance and, occasionally, precise repair.

The longevity and sustained accuracy of these components depend heavily on strict operational discipline and effective restoration techniques. For the rare instance of minor surface scratches or a dulling of the finish, specific protocols must be followed to restore the component without compromising its critical flatness. Light surface wear can often be addressed effectively using specialized commercial granite cleaners and conditioning agents designed to enhance the stone’s protective barrier and lift surface contaminants. For deeper abrasions, the intervention requires skilled technical application, often involving fine-grade steel wool followed by electric polishing to restore the luster. Crucially, this restoration must be executed with extreme care, as the polishing action must not, under any circumstances, alter the component’s critical geometry or flatness tolerance. Simple cleaning practices also dictate using only a mild, pH-neutral detergent and a slightly damp cloth, immediately followed by a clean, soft cloth to thoroughly dry and buff the surface, strictly avoiding corrosive agents like vinegar or soap, which can leave damaging residues.

Maintaining a contaminant-free working environment is just as vital as the repair process itself. ZHHIMG® mandates strict operational discipline: before any measurement task commences, the working surface must be rigorously wiped down with industrial alcohol or a designated precision cleaner. To prevent measurement errors and surface wear, operators must strictly avoid touching the granite with hands contaminated by oil, dirt, or sweat. Furthermore, the structural integrity of the setup must be verified daily to ensure the reference plane has not shifted or developed any undue inclination. Operators must also recognize that although granite possesses a high hardness rating (6-7 on the Mohs scale), striking or forcefully rubbing the surface with hard objects is strictly forbidden, as this can introduce localized damage that compromises global accuracy.

Beyond daily operational care, protective treatments for the non-working surfaces are essential for long-term stability, particularly in humid or wet-set environments. The back and side surfaces of the granite component require a dedicated waterproofing treatment before installation, a measure vital for preventing moisture migration and mitigating the risk of rust stains or yellowing, which are common in some gray or light-colored granites exposed to damp conditions. The selected waterproofing agent must not only be effective against moisture but must also be fully compatible with the cement or adhesive used for wet-setting, ensuring the bond strength remains uncompromised. This comprehensive approach, blending careful restoration techniques with rigorous operational discipline and specialized waterproofing, ensures that ZHHIMG® granite machine components continue to deliver the sustained accuracy and reliability demanded by the world’s most advanced metrology and manufacturing processes.

Post time: Nov-20-2025