In the CNC numerical control equipment industry, precision, stability and durability are the key indicators for measuring the performance of equipment. Granite, with its outstanding physical and chemical properties, has gradually become an important material in the manufacturing of CNC equipment and is widely used in various key devices, injecting new impetus into the development of the industry.

I. Application Scenarios of Granite in CNC Numerical Control Equipment

High-precision machining center base

In fields such as precision mold processing and aviation parts manufacturing, extremely high requirements are placed on the positioning accuracy and repeat positioning accuracy of machining centers. Granite, with its excellent stability, is often used as the base material for high-end machining centers. Its dense structure and high rigidity can effectively support the core components of the machine tool such as the spindle and guide rails, reducing processing errors caused by base deformation. For example, when processing the molds of aero engine blades with complex curved surfaces, the machining center using a granite base can ensure the precise execution of the tool path and improve the forming accuracy of the molds.

2. Three-coordinate measuring machine platform

The three-coordinate measuring machine is a key equipment for quality inspection in CNC machining, and its measurement accuracy directly affects product quality. Granite platforms, with their extremely high flatness (up to ±0.1μm/m) and very low surface roughness (Ra≤0.02μm), provide a stable reference surface for measuring probes. When inspecting the dimensions, shapes and positional tolerances of precision parts, granite platforms can effectively avoid measurement errors caused by their own deformation or uneven surfaces, ensuring the accuracy and reliability of the inspection data.

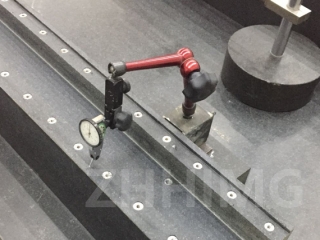

3. Guide rails for CNC machine tools

The performance of the guide rail determines the smoothness and accuracy of the machine tool's movement. Granite guide rails feature a low coefficient of friction and strong wear resistance. Compared with metal guide rails, they can reduce the wear of moving parts and lower the frequency of maintenance. Meanwhile, its excellent damping performance can effectively absorb the vibration during the operation of the machine tool and improve the quality of the machined surface. In high-speed cutting processes, granite guide rails can keep the cutting tool in a stable cutting state, reduce the surface roughness of the workpiece, and improve processing efficiency and product quality.

4. Electrical discharge machining machine tool worktable

During the electrical discharge machining process, high temperatures and electromagnetic interference are generated, which places high demands on the stability and insulation of the worktable. Granite not only has excellent thermal stability, capable of withstanding temperature changes during processing, but also has natural insulation properties and is not affected by electromagnetic interference. Therefore, granite workbenches can provide a stable working environment for electrical discharge machining, ensuring processing accuracy and surface quality.

Ii. Core Advantages of Granite in CNC Numerical Control Equipment

Outstanding thermal stability

During the long-term continuous operation of CNC equipment, a large amount of heat is generated, causing the thermal expansion and contraction of the equipment components. The coefficient of thermal expansion of granite is extremely low (only 4-8 ×10⁻⁶/℃), and its size remains almost unchanged when the temperature changes, which can effectively avoid processing errors and measurement deviations caused by thermal deformation. For instance, in high-temperature environments, CNC equipment with granite bases can still maintain stable processing accuracy, ensuring that product quality is not affected by temperature fluctuations.

2. Excellent anti-vibration performance

During the CNC machining process, the high-speed operation of the machine tool and the cutting force will cause vibration, affecting the machining accuracy and surface quality. The unique crystal structure inside granite endows it with excellent damping performance, enabling it to rapidly attenuate external vibration energy and minimize vibration interference. Experimental data show that the damping ratio of granite can reach 0.05-0.1, which is 5-10 times that of metal materials. It can effectively reduce tool vibration and the waviness of the workpiece surface, and improve processing accuracy and surface finish.

3. High rigidity and wear resistance

Granite has a high density (up to 2.6-3.0g /cm³) and great hardness (with a Mohs hardness of 6-7), and it features excellent rigidity and wear resistance. When subjected to the heavy loads and frequent mechanical movements of CNC equipment, granite components are not prone to deformation or wear and can maintain a high-precision state for a long time. According to statistics, the precision retention time of CNC equipment using granite components can be 3 to 5 times longer than that of traditional metal equipment, significantly reducing equipment maintenance costs and downtime.

4. Strong chemical stability

In the CNC machining process, chemical reagents such as cutting fluids and lubricants are often used, and these substances may cause corrosion to the equipment components. Granite has stable chemical properties, a wide pH tolerance range (1-14), can resist the erosion of common chemical substances, and is not prone to rust or corrosion. This feature not only extends the service life of the equipment components, but also ensures the cleanliness of the processing environment, avoiding the impact on product quality due to chemical pollution.

Against the backdrop of the CNC numerical control equipment industry's continuous pursuit of high precision and high efficiency, granite, with its advantages such as thermal stability, vibration resistance, high rigidity and chemical stability, plays an irreplaceable role in a variety of key equipment. With the continuous advancement of technology, granite materials will be more widely applied in the CNC field, promoting the industry to develop towards higher precision and higher quality.

Post time: May-24-2025